Road and workshop

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

by Handyman

Vehicle recovery tricks, trucks and tactics (5)

• Almost everyone in goods transport must be familiar with the sight of a set of differential chain blocks hanging above a loading dock. From time-to-time they will use them to swing some part of a load from dock to vehicle. But surprisingly few people other than certain repair staff know much about block and tackle, their design, capacity, and their various uses, particularly in recovery.

Before I discuss the mechanical advantage of various arrangements of blocks and tackles, it will be as well to examine the make up of different styles of block to obtain a clear picture of their design and duty. A block consists of a shell, strap, sheave and pin, with shackle or hook. The sheave, which is the running pulley or wheel, can be wood with a plain bush inserted, or a wood sheave with a roller bearing insert, or a metal sheave with roller bearing or self-lubricating bush.

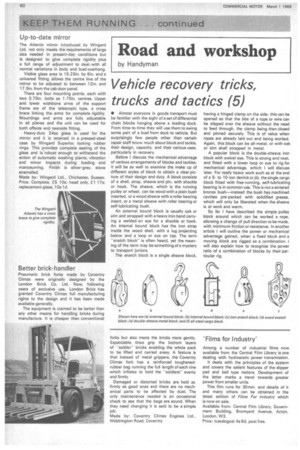

An external bound block is usually oak or elm and strapped with a heavy iron band carrying a welded-on eye for a shackle or hook. An internal bound block has the iron strap inside the wood shell, with a lug projecting below and a loop or eye on top. The term "snatch block" is often heard, yet the meaning of the term may be something of a mystery to transport juniors.

The snatch block is a single sheave block, having a hinged clamp on the side; this can be opened so that the bite of a rope or wire can be slipped over the sheave without the need to feed through, the clamp being then closed and pinned securely. This is of value when ropes are already laid out and being worked. Again, this block can be all-metal, or with oak or elm shell strapped in metal.

A popular block is the double-sheave iron block with swivel eye. This is strong and neat. and fitted with a lower loop or eye to rig for mechanical advantage, which I will discuss later. For really heavy work such as at the end of a 5to 10-ton derrick or jib. the single cargo block fitted with free-running, self-lubricating bearing is in common use. This is not a sintered bronze bush—instead the bush has machined cavities pre-packed with solidified grease, which will only be liberated when the sheave is at work and warm.

So far I have described the simple pulley block around which can be worked a rope, allowing a change of pull direction to be made, with minimum friction or resistance. In another article I will outline the power or mechanical advantage gained, when a fixed block and a moving block are rigged as a combination. I will also explain how to recognize the power ratio of a combination of blocks by their particular rig.