SAFETY FIRST IN COACH INSPECTION

Page 21

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

Vital Matters which Call for Careful Attention During a Chassis Overhaul. How a Weekly Inspection of Such Matters Should be Carried Out.

AS THE opening of the motor-coaching season is close upon us now, it is essential that the owners of such vehicles should fully realize the importance of making a good stait by thoroughly inspecting all vehicles Which are to operate in such service. Considering the huge numbers of passengers carried throughout the to-aching season, the number of accidents to life and limb of those who adopt this very pleasant and instructive method of travelling is infinitesimal, but, small as it is, it would be better were there no such accidents at all.,

Although the motor coach is one Of the safeet places one can be in, the public do not look always at the good side of such a matter, and are more likely to be prejudiced by a report of an accident, although it may be the only one during the whole year, than they would be guided by pages of figures pointing to the safety of the motor coach as a means of travelling. No one will deny that, from every point of view, accidents are best avoided.

Motor coaching is, of course, most popular in picturesque country, and picturesque country is usually hilly country. With few exceptions, those accidents which have happened have been due to failure of the brakes. In such cases one usually reads in the daily Press that " the brakes failed to act." Now, all motors must be fitted with two separate and independent brakes, and according to the law of chances it is extremely improbable that two brakes should " fail " at the same moment.

As brakes are constructed in British-made coaches, a failure of even one brake, provided it was in order when the journey was started, is almost an impossibility. With the brake lining materials available to' day, with all nuts split-pinned, etc., what can fail'? In the early days of the industry, when construction was not so well understood, there were many things which might account for a brake "failing," but today there is only one thing that can account for a brake refusing to act, and that is neglect and nothing else. In some cases, tampering has been the cause of failure, but this tampering can be usually traced to neglect. Neglect started the trouble, and tampering was resorted to to cover up.the result of the neglect. The writer has made a special study of such accidents and has been present. at more than one inquest, and, in his opinion, all recent accidents through brake failures were due to neglect. In the earlier days of the industry, some of the accidents were due to faulty design, and no amount of care on the part of those having charge of the vehicle could have prevented their happening. This, however, is. not the ease now, and there is no excuse for even one brake failing to act, and we all know the odds against a double event.

One of the commonest causes of brakes failing to develop their full power is the exuding of grease from the hub bearing. In the case of the brakes which were on the transmission, there was little -danger of this happening, but as this form of brake is fast disappearing, we must confine our remarks to wheel brakes. As most British -coaches are now made, the -brakes both operate inside one drum on the rear wheel. Although this form of brake has proved itself to be highly satisfactory in use, there is the danger that, shculd grease escape from the hub bearing, it may seriously reduce the effect of both brakes in that particular drum. In all makes of coach, there is provision for retaining oil in the hubs, and any serious escape can only be due to some part having worn badly or having been wrongly re-assembled at some time, as no coach chassisis now turned out by any firm of repute in which a serious leakage of grease at this part is possible provided all is in order.

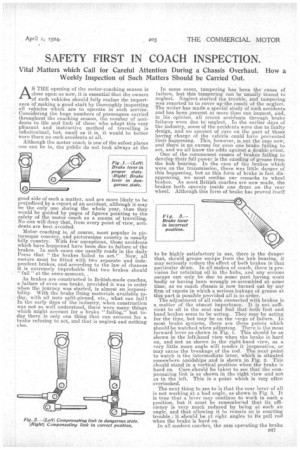

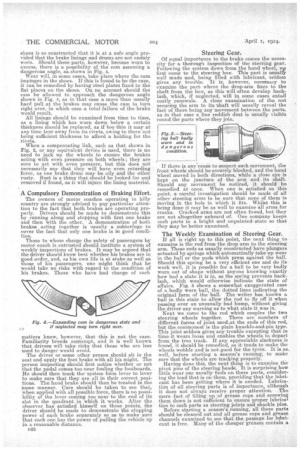

The adjustment of all rods connected with brakes is a matter of the utmost importance. It is not sufficient to sit in the seat and find that both foot and hand brakes seem to be acting.. They may be acting for the time, but may be on the verge of failure. In most brake systems, there are three points which should be Watched when adjusting.There is the most forward lever as shown in Fig. 1. This should be as shown in the left-hand view when the brake is hard on, and not as shownin the right-hand view, as a very little more angle will render it inoperative, or may -cause the breakage of the rod. The next point to watch is the intermediate lever, which is situated somewhere amidships and is shown in Fig. 2. This -should stand in a vertical position when the brake is hard on. Care should be taken to see that the compensating link is as shown in the right view and not as in the left. This is a point which is very often overlooked.

The next thing to see to 'is that the rear lever or all is not working at a bad angle, as shown in Fig. 3. It is true that a lever may continue to work in such a position, but it must be remembered that its efficiency is very much reduced by being at such an angle, and that allowing it to remain so is courting trouble ; it should be at right angles to its pull rod when the brake is hard en. In all modern coaches, the cam operating the brake D27

shoes is so 'constructed that it is at a safe angle provided that the brake linings and drums are not unduly worn. Should these parts, however, become worn to excess, there is a possibility of the cam assuming a dangeroue angle, as. shown in Fig. 4.

ear will, in some cases, take place where the cam impinges in the shoes. If this is found to be the case, it can be remedied by having steel plates fixed to the flat places on the shoes. On no account should the cam be allowed to approach the dangerous angle Shown in Fig. 4, as in that Case a more than usually hard pull at the brakes may cause the cam to turn right over, in which case a total failure of the brake would result.

All linings should be examined from time to time, as a lining which has worn down below a certain thickness should be replaced, as if -too thin it may at any time tear away from its rivets, owing to there not being sufficient thickness to afford a holding for the rivets.

When a compensating link, such as that shown in Fig. 2, or any equivalent device is used, there is no need to jack up the wheels to ensure the brakes acting with even pressure on both wheels ; they are sure to act with even pressure, but this does not necessarily say that they will have .evert retarding force, as one brake drum may be oily and the other rusty. Rust is a thing that should be looked for and removed if found, as it will injure the lining material.

A Compulsory Demonstration of Braking Effort.

The .owners of motor coaches operating in hilly country are strongly advised to pay particular attention to the fact that both brakes are operating properly. Drivers should be made to demonstrate this by running along and stopping with first one brake and then with the other. A demonstration of both brakes acting together is usually a subterfuge to cover the fact that only one brake is in good condition.

Those to whose charge the safety of passengers by motor coach is entrusted should institute a system of weekly inspections of brakes. It may be argued that the driver should know best whether his brakes are in good order, and, as his own life is at stake as well as those of his passengers, one might think that he would take no risks with regard to the condition of his brakes. Those who have had charge of such matters know, however, that this is not the case. Familiarity breeds contempt, and it is well known that drivers will take risks that those who are less used to danger would avoid.

The driver or some other person should sit in the seat and apply the foot brake with all his might. The person inspecting should first notice whether or not that the pedal comes too near fouling the footboards. He should then track the system form lever to lever to make sure that they are all in their correct i positions. The hand brake should then be treated n the name manner.Care should be taken to see that, when applied with all possible force, there is no possibility of the lever coming too near to the end of its slot in the quadrant in which it works. After the observer has satisfied himself on these points, the driver should be made to demonstrate the stopping power of each brake separately so as to make sure that each one has the power of pulling the vehicle up in a. reasonable distance.

D2B

Steering Gear.

Of equal importance to the brake comes the necessity for a thorough inspection of the steering gear. Following the system down from the hand wheel, wip first come to the steering box. This part is usuallY well made and, being filled with lubricant, seldom gives any trouble. It is, however, necessary to examine the part where the drop-arm fixes to the shaft from the box, as this will often develop backlash, which, if neglected, will in some cases entail costly renewals. A close examination of the nut securing the arm to its 'shaft will usually reveal the fact of then being any movement between the parts, as in that case a fine reddish dust is usually visible round the parts where they join.

If there is anicaule to suspect such movement, the front wheels should be securely blocked, and the hand wheel moved in. both directions, while a close eye is kept on the juncture of the arm and its shaft. Should any movement be noticed, it should be remedied at once. When one is satisfied on this. point, a careful investigation should be made of all other steering arms to be sure that none of them is moving in the hole in which it fits. Whilst this in being done it may be as well to examine all arms for cracks. Cracked arms are not often found, but they are not altogether unheard of. One company keeps such parts in a bright and unpainted state so that they may be better examined.

The Weekly Examination of Steering Gear.

If all is right up to this point, the next thing to examine is the rod from the drop arm to the steering arm. These rods as usually constructed have plungers actuated by springs which automatically take up wear in the ball or the pads which press against the ball. Should this spring be a very efficient one and do its work well, it is possible for a ball to be very badly worn out of shape without anyone knowing exactly how bad a state it is in, as the spring prevents backlash, which would otherwise indicate the state of affairs. Fig. 5 shows a, somewhat exaggerated case of a badly worn ball, the dotted lines indicating the original form of the ball. The writer has known a ball in this state to allow the rod to fly off it when passing over an unusually bad bump, without. giving the driver any warning as to what state it was in.

Next we come to the rod which couples the two steering wheels together. There are numbers of different forms of joint used.at the ends of this rod, but the commonest is the plain knuckle-and-pin type. This joint seldom gives any trouble excepting that in time it wears loose and enables the wheels to depart from the true track. If any appreciable slackness is found, it should be remedied, as it tends to make the wheels wobble and in not good for the tyres. It is aswell, before starting a season's running, to make sure that the wheels are tracking properly.

Having done this, the next thing is to examine the pivot pins of the steering heads. It is surprising how little wear one usually finds on these parts, considering the load that is on them, providing that the lubricant has been getting where it is needed. Lubrication of all steering parts is of importance, although it does not always receive proper attention. The mere fact of filling up of grease cups and screwing them down is not sufficient to ensure proper lubricai Lion to such parts as steering joints and shackle pine. Before starting a season's running, all these parts should be cleaned out and all grease cups and grease channels examined to see that the passage for lubricant is free. Many of the cheaper greases contain a

high proportion of-earthy matter. When the lubricant is pressed through the channels which direct it to the places where it is required, this earthy matter in many cases remains in the channels until they become clogged, consequently the lubricant fails in the future to reach the rubbing surfaces, which soon begin to wear unless the fault be rectified so soon as possible.

The condition of the vertical pins of the steering heads should be noted, as these, like all other working parts, will wear slack in ,time. The result of wear in these pins is not apparent while the weight of the vehicle is on them, as weight has the effect of jamming them sideways in their bushes, and their condition can only be ascertained by dismantling. Whilst there is; no danger to be anticipated from a certain amount= of wear in these parts there is the annoyance to passengers -caused through rattle when travelling over rough roads.

All parts connected with the steering of motor coaches should be examined weekly on lines similar

to the brake inspection recommended. To carry this out properly, the front wheels should be driven against a wall, or in some way prevented from steering. Whilst in this position some person should try to move the hand wheel, first in one direction, then in the other. There will always be a certain amount of backlash found in all steering gears—a certain amount is unavoidable. Should the backlash be ex. cessive, the cause should be traced out. It may be in the wormbox alone, in which case there is not much actual danger; but things should be seen to if it is excessive. In most cases, . it will be found where the drop arm joins,its shaft, or Where the steering arms fit in to the steering heads. In this case the remedy is plain, and matters should be put right immediately.The practice of keeping the steering arms bright instead of being painted is one that should be followed, as it is the outcome, of experience. By this means, a crack can be seen immediately. A weekly inspection should include a most careful examination of these levers for cracks.