VOLVO IS to introduce three new versions of its TD100

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

and T120 engines to Britain, which will be available from early next year.

As far as the UK operator is concerned, the most significant engine is the TD100 GA which rePlaces the TD100 B in the F10 series. It develops 192kW (257bhp) at 2,050rpm, compared with the 207kW (278bhp) at 2,200rpm of the earlier version.

If this seems a curious move, in that most manufacturers increase power output with a new engine, it is linked with Volvo's thoughts on total driveability within the usable power range, with the emphasis on "usable".

Thus maximum torque is increased from 1,000 to 1,060Nm (779 lbft) and this has been achieved at a lower engine speed. It is now at 1,300 compared with 1,400rpm.

The TD100 GA has now a '1,200 to 1,900rpm useful performance sector, with the torque never dropping more than ten per cent below the maximum.

Although the basic engine is still the long-serving 9.6-litre (586cuin) turbocharged sixcylinder unit, the increase in torque has not been achieved merely by increasing the fuel delivery and boost pressure. For a start, the turbocharger is different, with a claimed improvement in both turbine and compressor efficiency giving a more symmetric air flow through the turbocharger assembly.

In addition, the exhaust manifold has been reduced in cross-section to give a better pulse rate to the exhaust gases upstream of the turbine. The whole fuel-injection ar air-delivery system has been changed in order to improve combustion efficiency and th widen the speed range. The Wale Bosch pump is retainet though some of the internals hove been changed.

The plungers and delivery valves are different, and a modified camshaft has given higher opening pressure and thus a faster injection rate.

A rapid pressure rise is normally a prime cause of die combustion "crack", but the timing has been adjusted to compensate with the overall noise level, according to Volv ng no higher than with the the far end of the injection )ss, the nozzle diameter has increased, though the !spray angle has been led.

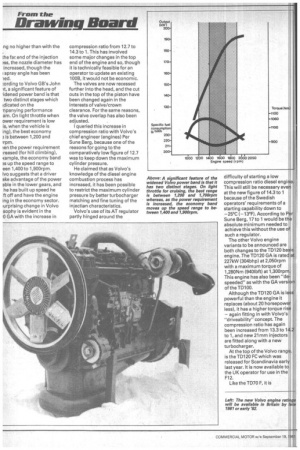

:ording to Volvo GB's John it, a significant feature of idened power band is that two distinct stages which idicated on the

npanying performance am. On light throttle when ower requirement is low is, when the vehicle is Ing), the best economy 3 is between 1,200 and Irpm.

ten the power requirement :reased (for hill climbing), Kample, the economy band ?.s up the speed range to een 1,400 to 1,900rpm. Ivo suggests that a driver ake advantage of the power able in the lower gears, and he has built up speed he ft off and have the engine ing in the economy sector. .urprising change in Volvo sophy is evident in the 0 GA with the increase in

compression ratio from 12.7 to 14.3 to 1. This has involved some major changes in the top end of the engine and so, though it is technically feasible for an operator to update an existing 100B, it would not be economic.

The valves are now recessed further into the head, and the cut outs in the top of the piston have been changed again in the interests of valve/crown clearance. For the same reasons, the valve overlap has also been adjusted.

I queried this increase in compression ratio with Volvo's chief engineer (engines) Per Sune Berg, because one of the reasons for going to the comparatively low figure of 12.7 was to keep down the maximum cylinder pressure.

He claimed that as Volvo's knowledge of the diesel engine combustion process has increased, it has been possible to restrict the maximum cylinder pressure by better turbocharger matching and fine tuning of the injection characteristics.

Volvo's use of its AT regulator partly hinged around the difficulty of starting a low compression ratio diesel engine. This will still be necessary even at the new figure of 14.3 to 1 because of the Swedish operators' requirements of a starting capability down to —25°C ( —13°F). According to Per Sune Berg, 17 to 1 would be the absolute minimum needed to achieve this without the use of such a regulator.

The other Volvo engine variants to be announced are both changes to the TD120 basic engine. The TD120 GA is rated at 227kW (304bhp) at 2,050rpm with a maximum torque of 1,280Nm (940Ibft) at 1,300rpm. This engine has also been "despeeded" as with the GA version of the TD100.

Although the TD120 GA is less powerful than the engine it replaces (about 20 horsepower less), it has a higher torque rise — again fitting in with Volvo's "driveability" concept. The compression ratio has again been increased from 13.3 to 14.2 to 1, and new 21mm injectors are fitted along with a new turbocharger.

At the top of the Volvo range, is the TD120 FC which was released for Scandinavia early last year. It is now available to the UK operator for use in the

F12.

Like the TD70 F, it is

turbocharged and charge-cooled using an air-to-air system to produce 265kW (355bhp) at 2,050rpm. The maximum torque is 1,550Nm (1,140Ibft) at 1,30Orpm Volvo claims that the air-to-air charge-cooler lowers the temperature of the inlet air to around 50°C (122°F) from 150° to 160°C (300° to 320'F). Volvo prefers the air-to-air layout because of its inherently higher efficiency in contrast to Scania which uses an air-to-water system with the DS18.

The significant feature of th 120FC is the vast increase in a of maximum efficiency plotte on the iso-consumption diagram. Plotting lines of constant sfc against torque ar engine speed, one is left with area within which the engine operating at peak efficiency.

Comparing the diagrams fo the turbocharged TD120C anc the turbocharged and chargecooled TD120FC, the improvement is readily apparent, with the maximum efficiency being maintained o a wide area.

Also launched last year for Scandinavia was the SR70 gearbox, which was develope to be capable of handling higi torque ratings without loss of reliability.

This box is used in conjunct with the TD120 FC and as such will be available in the UK as from December.

The SR70 has 12 speeds, pit two crawler ratios. The basic gate is a three-speed layout w a planetary range-change unit giving a further three speeds. with the SR62, a splitter opera on all gears giving a total of 1: speeds.

In fact, Volvo considered' putting larger gear wheels an bigger synchronisers into the S962, but finally decided on a brand new design as providin more scope for further development.

In contrast to the SR62, whi had the range-change switch the lever but the splitter selec. on the dash, the new SR70 ha both controls mounted on the lever.

All the gears are carried in either roller or needle bearing and are case hardened. Helica cut teeth have been specified quieter running.

Volvo claims that the new gearbox weighs 335kg (740 lb — a reduction of ten per cent over the SR62.

With these latest Volvo engines, the period between c changes has been doubled to 20,000km (12,500 miles) on lo distance machines and 10,000km (6,200 miles) for loc distribution work.

The new Volvo engines and the SR70 gearbox will probab be available in the UK by midDecember.