The Evolution of Modern Driving Chains.

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

(Continued from page 79 ) The figures published last week illustrated the steady progress in chain design from die crude chain of the " kangaroo " bicycle to the excellent tyims now used for motorcars. Improvement has not been limited to the design of the chains ; there has been even greater progress in the development of accurate duplicating machinery. All the links can now be turned out absolutely to the same standard gauge, without a hair's breadth of variation in any part, which perfection is partly due to the use of a class of steel that was previously unknown. If the time should ever come when the motorcar is displaced by some other method of locomotion, its era will always be remembered as the most potent factor in the introduction of the high-class steels of the present day. The demand for lighter and still lighter chains, to withstand not merely the same pull but a greater pull, has only been met by the use of steels of special cornposition and extremely high tensile strength. Hans Ronald. Limited, makes three classes of chains which are known as short-pitch chains, medium-pitch chains, and long-pitch chains, the various sizes ranging front ;in. to fun., but the longest links are not necessarily the strongest. A comparison between the various classes for equal pitches is as follows :— In the short-pitch class, those tin, pitch with a roller dia meter of .55in. will stand a breaking load of 4,000lb., or nearly two tons, whilst the iin. pitch chain, the roller diameter of which is .85in., will stand a breaking load of 4,500ib.-approximately 6-&tons. In the medium-pitch class, those tin, pitch with a roller diameter of .335in, will stand a breaking load of 1,98o1b., and the tin. pitch chain, the roller diameter of which is .55in., will stand a load of 4,000lb. In the long-pitch class, the lin. pitch chain, with a roller diameter of .3o5in.,.will stand a breaking load of 16,000lb„ and the 1-Ain. pitch chain, with a roller diameter of .410., will stand a breaking load of 25,000lb. It is worth while to consider what these loads mean. Yet, as the dependence of the lives of those riding on any motor vehicle may be at the mercy of a chain, it is a great comfort to realise that the metal will carry with safety such

enormous loads.

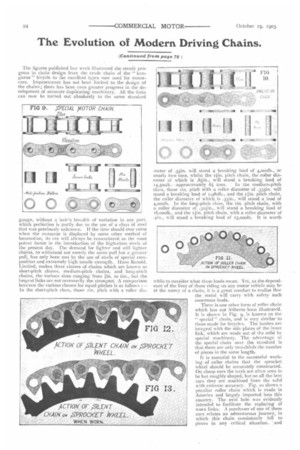

There is one other form of roller chain which has not hitherto been illustrated. It is shown in Fig, 9, is known as the " special " chain, and is very similar to those made for bicycles. The bushes are integral with the side plates of the inner link, which are made out of the solid by special machinery. The advantage of the special chain over the standard is that there are only two-thirds the number of pieces in the same length.

It is essential to the successful working of roller chains that the sprocket wheel should be accurately constructed. On cheap cars the teeth are often seen to be but roughly shaped, but on all the best cars they are machined from the solid with extreme accuracy. Fir,. to shows a peculiar roller chain which is made in America and largely imported into this country. The oval hole was evidently intended to facilitate the replacing Of worn links. ,A purchaser of one of these cars relates an adventurous journey, in which this chain consistently fell to pieces in any critical situation, and

cut in two all the way round the chain wheel. One great advantage of this form of chain is that it is unnecessary to increase the diameter of the chain wheels to take big loads. All that is necessary is to widen the face of the wheel, and to increase the number of links in the width of the chain.

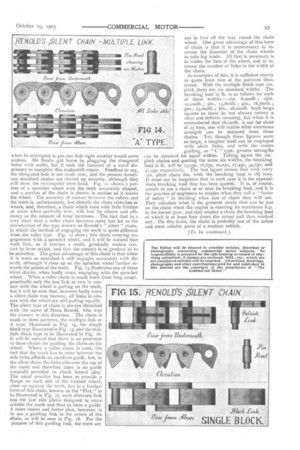

As examples of this, it is sufficient merely to quote from two of the patterns aimtrated. With the multiple block type tin. pitch there are six standard widths. The breaking load in lb. is as follows for each of these widths 8,acioib.; 2iin. 12,200lb.; 3in., 13,800lb.; fin., t8,7oolb.;

FIG IC 4A" TYPE.

AZ finks 8111e: 23,600lb.; din., 28,000lb. Such large iigures as these do not always convey a clear and definite meaning, but when it is remembered that 28,e00lb. is not far short of 13 tons, one will realise what enormous strength can be obtained from these chains. Yet, though these figures seem so large, a tougher steel can be employed with plate links, and with the centre guiding, or " C" type, greater strengths can be obtained for equal widths. Taking again the tin. pitch chains and quoting the same six widths, the breaking load in lb. will be 13,050, 16,650, 20,250, 27,450, 34,650, and 41.550 respectively. The last figure means that with every zin. pitch chain 61n. wide the breaking load is tons. It must not be forgotten that in each case it is the approximate breaking load that has been quoted. It is, of course, unsafe to use a chain at or near its breaking load, and it is the practice of engineers to employ what they call a "factor of safety " in deciding what size of chain they will use. They calculate what is the greatest strain that can be put on the chain when the engine is exerting its maximum h.p. in the lowest gear, and they employ a chain the breaking load of which is at least four times the actual pull thus worked Out. On this basis, the chain is probably one of the safest and most reliable parts of a modern vehicle.