BISCUIT DISTRIBUTION DEPE II

Page 14

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

ON CONTRACT TRANSPORT

WHEN passing through Carlisle it is hardly possible to overlook the huge factory of Carr and Co., Ltd.—Carrs of Carlisle—which proclaims itself as the birthplace of the biscuit industry. That is the headquarters of the spruce fleet which carries Carr's biscuits all over the country.

Thousands of visitors are welcomed and shown around the factory every year and, in a place of honour, they see the original biscuit-making machine—much like a printing press of the period—which was invented by Mr. Jonathan Dodgson Carr, who founded the business in 1831. The invention was destined to initiate rapid development in the industry. In 1841 Mr. Carr was appointed biscuit maker to H.M. Queen Victoria. Since that time the little factory has grown, and grown, and grown.

When founded in 1831, Mr. Carr's establishment was well situated to carry on a local trade, but the development of the business throughout the country, as well as embracing a considerable export trade, brought new problems. Carlisle might, consequently, well appear to be a much less attractive centre from the viewpoint of those charged with the important task of distribution.

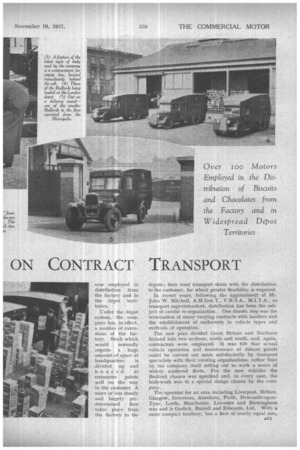

The Border City is remote from large centres of population. There is no water access, either natural or arti depots; then road transport deals with the distribution to the customer, for which greater flexibility is required. In recent years, following the appointment of Mr.

John W. Mitchell, A.M.Inst.T., M.I.T.A., as transport superintendent, distribution has been the subject of careful re-organization. One drastic step was the termination of many varying contracts with hauliers and the establishment of uniformity in vehicle types and methods of operation.

The new plan divided Great Britain and Northern Ireland into two sections, north and south, and, again, contractors were employed. It was felt that actual vehicle operation and maintenance at distant points could be carried out more satisfactorily by transport specialists with their existing organizations, rather than by the company itself setting out to work a series of widely scattered fleets. For the new vehicles the Bedford chassis was specified and, in every case, the bodywork was to a special design chosen by the company.

The operator for an area including Liverpool, Belfast, Glasgow, Inverness, Aberdeen, Perth, Newcastle-uponTyne, Leeds, Manchester, Leicester and Birmingham was and is Garlick, Burrell and Edwards, Ltd. With a more compact territory, but a fleet of nearly equal size,

so as to cope with denser traffic, is Keith and Boyle (London), Ltd., operating from Norwich, London, Southampton, Bristol, Cardiff and Plymouth.

In addition, the company itself operates five MorrisCommercial 2-ton vans (also with bodies of the specified design) on direct deliveries from the factory to Cumberland and the Border Country, and employs three MorrisCommercial lorries on work in and around Carlisle.

Payment to the contractors includes standing charges in relation to interest, profit, depreciation on a five-year basis, insurance, registration, administration, garage, washing and uniforms, also running costs (based on mileage), covering petrol, tyres, oil, grease and repairs. Further, the company is responsible for the drivers' wage bill.

Heavy Costs Eliminated .

In addition to the exclusive use of the fleet, the company has the right to call for spare vehicles to meet r requirements at rush periods. By the contract method of operation, heavy costs for maintenance work at points where only a few machines are used are avoided, whilst the advertising value and personal link between factory and retailer are just as effective as with a C-licence fleet. Although the service of transport specialists naturally has to be paid for, the company is convinced that none of the possible alternatives would offer any prospect of substantial savings.

The total number of vehicles in use is over 100, of which 55 are in the 30-cwt. class—a type that, with improving designs in van bodywork, has the greatest utility. The lightness of the goods to be carried makes capacity an important factor.

At present, other units of the fleet range from 12-cwt. to 40-cwt. capacity. A notable change that took place when the new body design was evolved was the elimination of the traditional roof rails that, in the past, denoted the biscuit-delivery van.

Instead of the returned empties "living" on the roof, in Carrs fleet they are provided with a special cubicle. When leaving the depot, the van is fully loaded, so far as the main section is concerned, but the cubicle is left free for tins collected on the early part of the journey. When the " empty " section is full, the load in the main compartment will have been reduced, thus leaving space for still more empties.

Special Bodywork .

On the smaller vehicles, access to the empties cubicle is obtained by way of the specially wide doors of the cab, but on the 2-ton and the later 30-cwt. machines a roller-shutter is located at the side. Early types had shutters on both sides, but as in practice only one was used, the redundant fitting was omitted. The 30-cwt. and 2-ton vehicles have narrow rear shutters, At first, the 30-cwt, type was designed to carry 380 of the well-known standard square tins, but improved design has brought the capacity up to nofewer than 565 tins, whilst the 2-ton class has jumped from a capacity of 611 tins to 706 tins. As already indicated, responsibility for all Work on the fleet lies with the contractor, and it is provided that, normally, the vehicles shall be washed each night, whilst overhauls and repaints shall take place at yearly intervals, so that a smart appearance is ensured.

Requisitions are received at the factory each day from the managers of the sales depots and goods are loaded into rail vehicles. Complete wagon loads reach the depots and are put into stock or passed on for immediate distribution by motor.

1314 Drivers and vehicles from the contractors come on duty according to a strict schedule that ensures that they shall not obstruct each other, as would happen if all reported at once. Loads are set out in delivery order and each man assists with the loading of his goods.

A radius not exceeding 60 miles from the depot is the standard for road delivery, but, naturally, this must be curtailed in congested districts and extended in areas such as the far north of Scotland. Working a fixed. list of journeys, the vans follow, so far as possible, the rounds of the company's travellers, although, in this connection, difficulty is frequently encountered, owing to the variations in. half-day closing customs which prevent the arrangement of schedules being anything like straightforward.

In addition to the usual data regarding weights, hours, etc., thd drivers' logsheets make provision for the entry of the number and types of tins taken out, the number of empties brought in, miles run, petrol used and drivers' expenses. These forms are forwarded to head office immediately they are completed, so that the transport superintendent can check the work done and its cost from week to week.

Before the sheet is returned, however, there are three questions on the back that have to be answered by the depot manager. They are : —Is the vehicle in first-class condition and to your entire satisfaction as regards the appearance of all bodywork, chromium plating, etc.? Has the van been regularly washed and cleaned throughout the week under review? Is the driver's uniform in order and neat and clean? Full uniform is, of course, provided.

A good proportion of the drivers has been employed with Carrs of Carlisle for lengthy periods, and their wages and conditions compare favourably withthose laid down by the National Joint Conciliation Board. The men work under the direct instructions of the depot managers andare engaged in straight delivery work, not normally collecting cash, although they are responsible for issuing credit notes for all empties collected, the notes being passed back to the depot for attention by the company's clerical staff.

In an average day, each driver will call on some 50 customers, although the rounds rary somewhat according to the distances and type of country. Altogeihez, the total mileage for the contract fleet during the year 1935-6 was 1,928,171,