Guy Six-wheeler with Underfloor 112 b.h.p. Engine

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

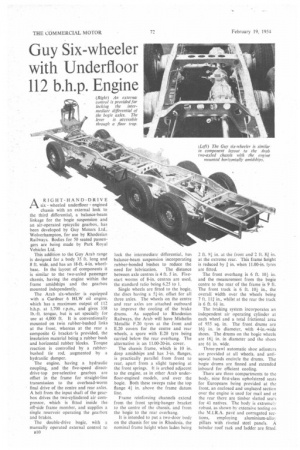

ARIGHT-HAND-DRIVE six wheeled underfloor engined chassis with an external lock to the third differential, a balance-beam linkage for the bogie suspension and an air-operated epicyclic gearbox, has been developed by Guy Motors Ltd., Wolverhampton, for use by Rhodesian Railways. Bodies for 50 seated passengers are being made by Park Roal Vehicles Ltd.

This addition to the Guy Arab range is designed for a body 35 ft. long and 8 ft. wide, and has an 18-ft. 4-in. wheelbase. In the layout of components it is similar to the two-axled passenger chassis, having the engine within the frame amidships and the gearbox mounted independently.

The Arab six-wheeler is equipped with a Gardner 6 HLW oil engine, which has a maximum output of 112 b.h.p. at 1,700 r.p.m., and gives 358 113.-ft. torque, but is set specially for use at 4,000 ft. It is conventionally mounted on twin rubber-bushed links at the front, whereas at the rear a composite G bracket-is provided, the insulation material being a rubber bush and horizontal rubber blocks. Torque reaction is controlled by a rubberbushed tie rod, augmented by a hydraulic damper.

The engine, having a hydraulic coupling, and the five-speed directdrive-top pre-selective gearbox are offset in the frame for straight-line transmission to the overhead-worm final drive of the centre and rear axles. A belt from the input shaft of the gearbox drives the two-cylindered air compressor. which is fitted inside the off-side frame member, and supplies a single reservoir operating the gearbox and brakes.

The double-drive bogie, with a manually operated external control to sl 0 lock the intermediate differential, has balance-beam suspension incorporating rubber-bonded bushes to reduce the

need for lubrication. The distance between axle centres is 4 ft. 5 in. Fivestart worms of 8-in, centres are used, the standard ratio being 6.25 to 1.

Single wheels are fitted to the bogie, the discs having a 51-in, offset for all three axles. The wheels on the centre and rear axles are attached outboard to improve the cooling of the brake drums. As supplied to Rhodesian Railways, the Arab will have Michelin 'Metallic F.20 tyres at the front and E.20 covers for the centre and rear wheels, a spare with E.20 tyre being carried below the rear overhang. The alternative is an 11.00-20-in, cover.

The chassis frame, which is 10 in. deep amidships and has 3-in, flanges, is practically parallel from front to rear, apart from a slight tapering at the front springs. It is arched adjacent to the engine, as in other Arab underfloor-engined models, and over the bogie. Both these sweeps raise the top flange 41 in. above the frame datum line.

Frame reinforcing channels extend from the front spring-hanger bracket to the centre of the chassis, and from the bogie to the rear overhang.

It is intended to put a two-door body on the chassis for use in Rhodesia. the nominal frame height when laden being 2 ft. 9.1. in. at the front and-2 ft. 81 in. at the extreme rear. This frame height is reduced by in. when 11.00-in. tyres arc fitted.

The front overhang is 6 ft. 10f in. and the measurement from the bogie centre to the rear of the frame is 9 ft. The front track is 6 ft. 10f in., the overall width over the wheels being 7 ft. 11,1 in., whilst at the rear the track is 6 ft. 6+ in.

The braking system incorporates an independent air operating cylinder at each wheel and a total frictional area of 935 sq. in. The front drums are 16f in. in diameter, with 4-in.-wide shoes. The drums on the bogie wheels are 161 in. in diameter and the shoes are 6+ in. wide.

Three-pawl automatic shoe adjusters are provided at all wheels, and antisqueal bands encircle the drums. The bogie drums are finned and extended inboard for efficient cooling.

There are three compartments to the body, nine first-class upholstered seats for Europeans being provided at the front, an enclosed and unglazed sectien over the engine is used for mail and at the rear there are timber slatted sews for 41 natives. The body is extremely robust, as shown by extensive testing on the M.I.R.A. pave and corrugated sections, employing aluminium-alloy pillars with riveted steel panels. A tubular roof rack and ladder are fitted.