Vanadium Steel:

Page 28

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

(Concluded from page 152.)

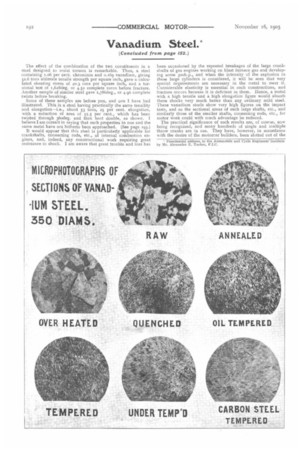

The effect of the combination of the two constituents in a steel designed to resist torsion is remarkable. Thus, a steel containing r.o6 per cent. chromium and 0.569 vanadium, giving 52.6 tons ultimate tensile strength per square inch, gave a calculated shearing stress of 40.3 tons per square inch, and a torsional test of r,628deg. or 4.52 complete turns before fracture. Another sample of similar steel gave 1,786deg., or 4.96 complete twists before breaking.

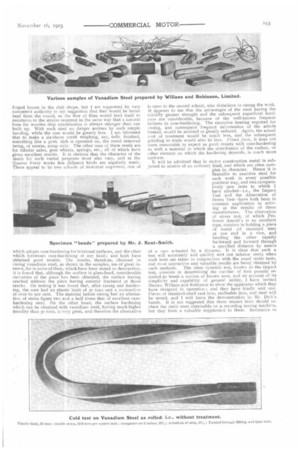

Some of these samples are before you, and one I have had illustrated. This is a steel having practically the same tensility and elongation--i.e., about 53 tons, 25 per cent. elongation, with a reduction of area of 55.5 per cent., which has been twisted through 36odeg. and then bent double, as shown. I believe I am correct in saying that such properties in one and the same metal have not hitherto been approached. (See page 193.}

It would appear that this steel is particularly applicable for crankshafts, connecting rods, etc., of internal combustion engines, and, indeed, any constructional work requiring great resistance to shock. I am aware that great trouble and loss has

been occasioned by the repeated breakages of the large crankshafts of gas engines working on blast furnace gas and developing some 5oah.p., and when the intensity of the explosion in these large cylinders is considered, it will be seen that very special requirements are necessary in the metal to meet it. Considerable elasticity is essential in such constructions, and fracture occurs because it is deficient in them. Hence, a metal with a high tensile and a high elongation -figure would absorb these shocks very much better than any ordinary mild steel. These vanadium steels show very high figures on the impact tests, and so the sectional areas of such large shafts, etc., and similarly those of the smaller shafts, connecting rods, etc., for motor work could with much advantage be reduced.

The practical significance of such results arc, of course, now being recognised, and many hundreds of single and multiple throw cranks are in use. They have, however, in accordance with the desire of the motorcar builders, been slotted out of the forged bloom in the slab shape, but I am supported by very competent authority in my suggestion that they would be better bent from the round, as the flow of fibre would lend itself to resistance to the strains required in the same way that a natural knee for wooden ship construction is always stronger than one built up. With such steel no danger accrues by such simple bending, while the cost would be greatly less. I am informed that to make a six-throw crank weighing, say, both, finished, something like a 3cwt. slab is operated on, the metal removed being, of course, scrap only. The other uses of these steels aro for tubular axles, gear wheels, springs, etc., all of which have given excellent results. It is obvious that the character of the steels for such, varied purposes must also vary, and at the Queens Ferry works five different kinds are regularly made. There appear to be two schools of motorcar engineers, one of

which adopts case-hardening for frictional surfaces, and the other which forswears ease-hardening, of any kind ; and both have obtained good results. The results, therefore, obtained in casing vanadium steel, as shown in the samples, are of great interest, for in some of them, which have been tested to destruction, it is found that, although the surface is glass-hard, considerable curvature of the piece has been obtained, the surface having cracked without the piece having entirely fractured at those cracks. On testing it was found that, after casing and hardening, the core had an elastic limit of 30 tops and a contraction of over 6o per cent. The material before casing hail an alternation of stress figure two and a half times that of excellent casehardening steel. On the other hand, the surface hardening which can be obtained with vanadium steel, having much higher tensility than 30 tons, is very great, and therefore the alternative

is open to the second school, who disbelieve in casing the work. It appears to me that the advantages of the steel having the initially greater strength and the subsequent superficial hardness are considerable, because of the well-known frequent failures in case-hardening. The excessive heating required for casing, and consequent frequent deformation of the article treated, would be avoided or greatly reduced. Again, the actual cost of treatment would he much less, and the subsequent grinding to truth would also be less, Prima facie, it does not seem reasonable to expect as good results with case-hardening as with a. material in which the distribution of the carbon, or other element on which the hardening depends, is much more uniform.

It will be admitted that in motor construction metal is subjected to strains of no ordinary kind, and which are often complex in character. Hence it is desirable to examine steel for such work in every possible practical way, and two comparatively new tests to which I have alluded—i.e., the Impact Test and the Alternation of Stress Test—have both been in constant application in arriving at the results of these manufactures. The alternation of stress test, of which Professor Arnold's is an excellent type, consists in holding a piece of metal (of standard size) at one end in a vice, and bending the other rapidly backward and forward through a specified distance by means of a cam actuated by a dynamo. It is clear that such a test will accurately and quickly sort out inferior steels when such tests are taken in conjunction with the usual static tests, and most instructive and valuable results are being obtained by such methods. The other dynamic test, known as the impact test, consists in determining the number of foot pounds re• quired to break a section of known area, and on account of its simplicity and capability of general utility, I have invited Messrs. Wiltans and Robinson to show the apparatus which they have designed in operation ; and they have kindly sent one. Pieces of standard-sized cast iron, malleable iron, and steel will be tested, and I will leave the demonstration in Mr. Dick's hands. It is not suggested that these impact tests should replace the static tests obtainable on a recording testing machine, hut they form a valuable supplement to them. Resistance to Kent-Smith.

shock can be definitely measured by the tensile test, using an extensometer, but, as v7il1 be shown, if it can be indicated very comparatively by the single pendulum one-blow method, the practical advantage in point of general convenience and rapidity is obviously very great.

I cannot conclude this paper without recording my obligatious to my friend, Mr. Kent-Smith, who has pioneered this steel to its present position, and who has permitted me to place the Jesuits of his researches before you. 1 have also to thank Messrs. Willans and Robinson for the loan of the samples.