The Equipment and Organisation of a Motor Repair Shop or Running Shed.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

SIXTH ARTICLE.

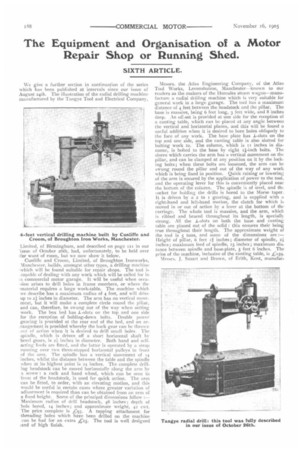

We give a further section in continuation of the series which has been published at intervals since our issue of August 241.11. The illustration of the radial drilling machine manufactured by the Tangye Tool and Electrical Company, 4-feet vertical drilling machine built by Cunliffe and Croom, of Broughton Iron Works, Manchester.

Limited, of Birmingham, and described on page 121 in our -issue of October 26th, had unfortunately, to be held over for want of room, but we now show it below.

Cunliffe and Croom, Limited, of Broughton Ironworks, Manchester, builds, amongst other types, a drilling marhine • which will be found suitable for repair shops. The tool is capable of dealing with any work which will be called for in :a commercial motor garage. It will be useful when men

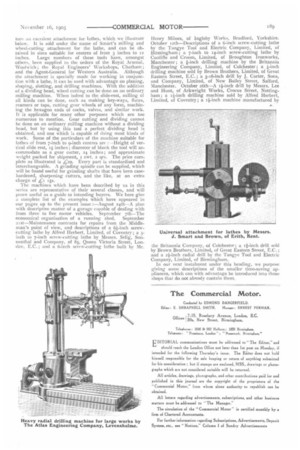

• sion arises to drill holes in frame members, or where the -material requires a large work-table. The machine which we describe has a maximum radius of 4 feet, and will drive up to 21 inches in diameter. The arm has no vertical movement, but it will make a complete circle round the pillar, and can, therefore, be swung out of the way when setting work. The box bed has 1-slots on the top and one side for the reception of holding-down bolts. Double power gearing is provided at the rear end of the bed, and an arrangement is provided whereby the back gear can be thrown out of action when it is desired to drill small holes. The spindle, which is driven off a short horizontal shaft b■ 'bevel gears, is '4 inches in diameter. Both hand and selfacting feeds are fitted, and the latter is operated by a strap running over two three-stepped horizontal pulleys in front of the arm. The spindle has a vertical movement of 14 'inches, whilst the distance between the table and the spindle when at its highest point is 24 inches. The complete drilling headstock can be moved horizontally along the arm by a screw : a rack and hand wheel, which can be seen in 'front of the headstock, is used for quick action. The arm can be fitted, to order, with an elevating motion, and this would be useful in certain cases where greater variation of adjustment is required than can be obtained from an arm of a fixed height. Some of the principal dimensions follow :— Maximum radius of drill headstock, 48 inches ; depth of "hole bored, 14 inches ; and approximate weight, 42 cwt. The price complete is L:93. A tapping attachment for • threading holes which have been drilled on the machine can be had for an extra 4.is. The tool is well designed and of 'high finish, Messrs. the Atlas Engineering Company, of the Atlas Tool Works, Levenshultne, Manchester—known to our readers as the makers of the Hercules steam wagon—manufacture a radial drilling machine which is very suitable for general work in a large garage. The tool has a maximum distance of 4 feet between the headstock and the pillar. The base is massive, being 6 feet long, 3 feet wide, and 8 inches deep. :In off-set is provided at one side for the reception of a canting table, which can be placed at any angle between the vertical and horizontal planes, and this will be found a useful addition when it is desired to bore holes obliquely to the face of any work. The base plate has 1-slots on the top and one side, and the canting table is also slotted for bolting work to. The column, which is it inches in diameter, is bolted to the base by eight ti-inch bolts. The sleeve which carries the arm has a vertical movement on the pillar, and can be clamped at any position on it by the locking bolts; when these bolts are loosened, the arm can be swung round the pillar and out of the way of any work which is being 6xed in position. Quick raising or lowering of the arm is secured by the application of power to the tool, and the operating lever for this is conveniently placed near the bottom of the column. The spindle is of steel, and the Socke t for holding the drills is bored to the Morse taper. It is driven by a a to i gearing, and is supplied with a right-hand and left-hand motion, the clutch for which is moved in or out of action by a lever at the bottom of the carriage. The whole tool is massive, and the arm, which is ribbed and braced throughout its length, is specially strong. All the _l_-slots on both the base and canting table are planed out of the solid : this ensures their being true throughout their length. The approximate weight of the tool is 5 tons, and some of the dimensions are 'Height of pillar, 6 feet mi inches; diameter of spindle, 2•41. inches ; maximum feed of spindle, 15 inches; maximum distance between spindle and base-plate, 5 feet 6 inches. The price of the machine, inclusive of the canting table, is .4;159.

Messrs. J. Smart and Brown, of Erith, Kent, manufac

Lure an exceilent attachment for lathes, which we illustrate below. It is sold under the name of Smart's milling and wheel-cutting attachment for the lathe, and can be obtained in sizes suitable for centres of from 3 inches to 12 inches. Large numbers of these tools have, amongst -others, been supplied to the orders of the Royal Arsenal, 'Woolwich ; the Royal Engineers' Workshops, Chatham ; and the Agent-General for Western Australia. Although the attachment is specially made for working in conjunction with a lathe, it can be used with advantage on planing, shaping, slotting, and drilling machines. With the addition of a dividing head, wheel cutting can be done on an ordinary milling machine. When bolted to the slide-rest, milling of all kinds can be done, such as making key-ways, flutes, reamers or taps, cutting gear wheels of any form, machining the hexagon ends of cocks, valves, and similar work. It is applicable for many other purposes which are too numerous to mention. Gear cutting and dividing cannot be done on an ordinary milling machine without a dividing head, but by using this tool a perfect dividing head is obtained, and one which is capable of doing most kinds of work. Some of the particulars of the machine suitable for lathes of from 7-inch to 9-inch centres are : —Height of vertical slide rest, 15 inches ; diameter of blank the tool will accommodate as a gear cutter, 24 inches; and approximate weight packed for shipment, i cwt. 2 qrs. The price complete as illustrated is .20. Every part is standardised and interchangeable. A grinding spindle can be supplied, which will be found useful for grinding shafts that have been casehardened, sharpening cutters, and the like, at an extra charge of Li 15s.

The machines which have been described by us in this series are representative of their several classes, and will prove useful as a guide to intending buyers. We here give a complete list of the examples which have appeared in our pages up to the present issue :—August 24th—A plan with descriptive matter of a garage capable of dealing with from three to five motor vehicles. September 7th—The economical organisation of a running shed. September 21st—Maintenance contracts for repairs from the Middleman's point of view, and descriptions of a 61-inch screwcutting lathe by Alfred Herbert, Limited, of Coventry; a 5inch to 7-inch screw-cutting, lathe by Messrs. Selig, Sonnenthal and Company, of 85, Queen Victoria Street, London, E.C. ; and a 6-inch screw-cutting lathe built by Mr. ihenry Milnes, of Ingleby Works, Bradford, Yorkshire. October 12th—Descriptions of a 6-inch screw-cutting lathe by the Tangye Tool and Electric Company, Limited, of Birmingham ; a 7-inch to 4-inch screw-cutting lathe by Cunliffe and Groom, Limited, of Broughton Ironworks, Manchester; a 1-inch drilling machine by the Britannia Engineering Company, Limited, of Colchester; a -inch drilling machine sold by Brown Brothers, Limited, of Great Eastern Street, E.G. ; a 5-16-inch drill by J. Carter, Sons, and Company, Limited, of New Bailey Street, Salford, Manchester. October 26th—A fl-inch drill by Messrs. Lee and Hunt, of Arkwright Works, Crocus Street, Nottingham; a ti-inch drilling machine sold by Alfred Herbert, Limited, of Coventry ; a fl-inch machine manufactured by

the Britannia Company, of Colchester; a i.-inch drill sold by Brown Brothers, Limited, of Great Eastern Street, E.C.; and a 21-inch radial drill by the Tangye Tool and Electric Company, Limited, of Birmingham.

In our next instalment under this heading, we purpose giving some descriptions of the smaller time-saving appliances, which can with advantage be introduced into those shops that do not already contain them.