Alloy Tubular Construction Reduces Body Weight

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

•

Reduces Body Weight

•

(Left) The British Tubular Construction Co., Ltd., built the 1,000-cubic-ft. body of this Dennis van, which has tubular pillars and flash-fitting panels. The vehicle weighs under 2+ tons.

SUBSTANTIAL reduction in weight, yet greater strength, as compared with coachbuilt bodywork, is a ,feature of new constructional methods used by an Aintree company. Half-tubular alloy sections are responsible for this advantage.

This method of building, combined with other specialities of the manufacturer, the British Tubular Construction Body Co., Ltd_ Albany Road, Aintree, Liverpool, makes the products of particular interest. Actually, the tubular construction has been the subject of lengthy practical tests, for' customers have had vehicles of this type in service for periods up to 12 months,

One such model, which left the works a year ago, is claimed to have been the first A.E.C. of maximum size and capacity to have been licensed with an unladen weight under 6 tons. The body—which measures 25 ft. by 8 ft. 6 ins. by 7 ft. 6 ins.—added only a ton to the weight of the A.E.C. Mammoth chassis, but, without trouble, it has continuously handled a 12-ton load, usually consisting of .3,200 tins of biscuits, throughout the period.

Various developments have now been completed and the company is ready to

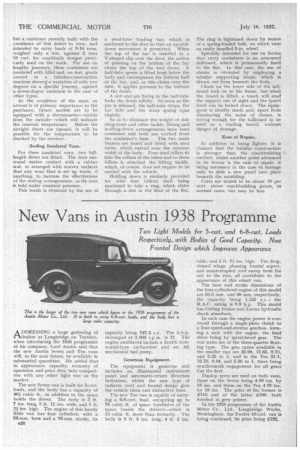

deal with orders-Al:4n the public. • Pillars and roof supports of wood are replaced by similar fittings made from light alloy in the form shown in the accompanying sketch. The tubular member, is keyed on the outside, panels, with their pressed-over edges, fitting to

the keyed section. The pillar and panels are held firmly together by the moulding that slides over them.

Pillars are bolted to the main bearers and cant-rails by means of angle brackets and the panels are normally 2 it to 2 ft, 6 ins, wide, so that the pillars ;Ind roof supports occur at similar intervals. To give added stability, two or three cross-straps are fitted between the pillars.

One effect of the tubular construction is great lateral .strength and the body is stated to resist any tendency towards distortion caused by a load settling and its weight resting upon the sides.

This is particularly liable to occur in the carriage of frozen meat carcasses,

but a container recently built with the avoidance of this defect in view, and intended to carry loads of 9-10 tons, weighed only a ton, against 2 tons 18 cwt, for coachbuiit designs previously used on the work. For use on lengthy journeys, these containers are insulated with Alfol and, on test, goods carried • in a tubular-construction machine showed a variation Of only two degreeson a specific journey,, against a seven-degree variation in the case of other types.

As the condition of the meat on arrival is of primal), importance to the purchaser, future models are to be equipped with a thermometer—visible from the outside—which will indicate the internal temperature. Before the airtight doors are opened, it will be possible for the temperature to be checked by the receiver.

Seating Insulated Vans.

For these insulated vans, two fulllength doors are fitted. The door surround makes contact with a rubber seal, so arranged with convex surfaces that any wear that is set up tends, if anything, to increase the effectiveness of the sealing arrangements, as the door is held under constant pressure.

This result is obtained by the use of a steel-tube loading bar, which is anchored to the door so that an up-anddown movement is permitted. When the top of the bar is inserted in a V-shaped clip over the door, the action of pressing on the bottom of the bar closes the top of the two doors. A half-tube spoon is lifted from below the body and encompasses, the bottom half of the bar, and, as this closes over the tube, it applies pressure to the bottom of the doors.

A slot and pin fixing in the half-tube locke the doors solidly. So soon as the pin is released, the half-tube drops, the bar falls and the doors spring open slightly.

So as to eliminate the weight of side sling-irons and other tackle, lifting and holding-down arrangements. have been combined and both are worked from the container's base. The two main bearers are bored and fitted with steel tubes, which extend over the extreme width of the body. Four steel billets fit into the collars of the tubes and to these billets is attached the lifting tackle, which, of course, does not require to be carried with the vehicle.

Holding down is ,similarly provided for with four billets, each being machined to take a ring, which slides through a slot in the floor of the flat.

The ring is tightened down by means of a spring-loaded bolt, on which -runs an easily handled 5-in. wheel.

Specially intended for-use on lorries that carry containers is ass armoured tailboard, which is permanently fixed to the fiat. In this' case, the use of chains is obviated by employing a tubular supporting. frame, Which is drawn out from beneath the body.

'Cleats on the lower side of the tai17 board lock on to the frame, birtiwhen the board is lifted, a touch will send the" simport out of sight and the board itself can be locked down. The equipment is stoutly made and, apart from eliminating the noise of chains, is strong enough for the tailboard to be used as a loading board, without danger of damage.

Ease of Repair.

In addition to being lighter, it is claimed that the tubular construction is stronger than the coachbuilifing method, whilst another point advanced in its favour is the ease of repair, it being necessary in the case of damage only to slide a new panel into place beneath the molding.

Costs are stated to be about 30 per cent, above coachbuilding prices, in normal cases, hist may be less.