A BRS manager

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

in the cupboard by Johnny Johnson

The alternatives to buying vehicles for own transport operation might be many, but one Newport timber importer has its own Western BRS depot on the premises complete with manager

THE high price of vehicles alone among the constantly escalating cost of transport is making the operation of own transport by supply services and manufacturers less and less attractive. The growing trend toward contract hire is proof of this.

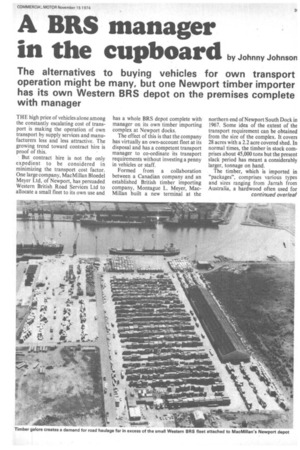

But contract hire is not the only expedient to be considered in minimizing the transport cost factor. One large company, MacMillan Bloedel Meyer Ltd, of Newport, has persuaded Western British Road Services Ltd to allocate a small fleet to its own use and has a whole BRS depot complete with manager on its own timber importing complex at Newport docks.

The effect of this is that the company has virtually an own-account fleet at its disposal and has a competent transport manager to co-ordinate its transport requirements without investing a penny in vehicles or staff.

Formed from a collaboration between a Canadian company and an established British timber importing company, Montague L. Meyer, MacMillan built a new terminal at the northern end of Newport South Dock in 1967. Some idea of the extent of the transport requirement can be obtained from the size of the complex. It covers 28 acres with a 2.2 acre covered shed. In normal times, the timber in stock comprises about 45,000 tons but the present slack period has meant a considerably larger, tonnage on hand.

The timber, which is imported in packages", comprises various types and sizes ranging from Jarrah from Australia, a hardwood often used for continued overleaf railway sleepers, to softwood from Canada, Scandinavia and Russia. As well there are other forest products to be distributed throughout the United Kingdom such as Kraft liner board, chipboard, and newsprint. Metal ingots are also imported from Canada.

Though mostly derived from one source, the traffic is, therefore, somewhat varied.

Because of the implication of vessel detention, cargo is rarely loaded on to vehicles straight from the hold. It is usually unloaded and carried into stock, either in the open air or under cover according to its nature, by fork-lift trucks. Macmillan then sells from stock on a countrywide basis. The depot at Newport supplies the demand from the western side of the country up to Scotland and another of the company's depots at Tilbury supplies the eastern side. This, too, incidentally, is serviced by BRS vehicles.

40 trailers

The nucleus of the transport fleet is the nine tractive units and 40 trailers provided by Western BRS. This is sufficient to handle the hard core of the timber distribution on a fairly local basis. Additional units are hired by BRS depot manager, Alan Beese, as the demand develops beyond this capacity.

This is done on a loose priority system taking first any available haulage strength from other BRS depots and then progressing to other independent hauliers on the basis of those having satisfactorily undertaken work in the past being approached first.

The demand for vehicles to convey timber from the depot considerable distances can be far in excess of the Western BRS capacity to fulfil it. In the spring of this year, for instance, timber was being consigned at the rate of over 2,000 tons a day. This involved the use of something like 12532-ton vehicles some running as far as Scotland.

All that the company needs to do in this case is to supply a daily schedule of tonnage of types and sizes of timber to particular destinations. Depot manager Alan Beese then determines the numbers and types of vehicles required and establishes their availability from the sources at his disposal and orders them for the time required.

Military operation

As the vehicles enter the depot they are directed to the appropriate timber holding area and, in collaboration with MacMillan's own staff, they are loaded by fork-lift truck.

At the peak, such as during the spring when the quoted number of vehicles each day was involved, the whole business is conducted like a military operation. Anything less would result in vehicles being detained unnecessarily because the fork-lift truck capacity was unable to cope.

In effect, this would increase costs and render the operation not viable. Moreover, the delay incurred could mean a customer having men idle waiting for timber. A situation to be avoided at all costs.

With an annual throughput of something like half a million tons a year, the depot obviously creates a huge demand for road transport. When it is realized that as much as 6,000 tons can be landed in one day and perhaps over 17,000 tons in a week, then its dependence on the efficiency and availability of road transport to keep the timber flowing becomes apparent.