WAYS AND MEANS.

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions from Our Driver and Mechanic Readers.

More About Petrol Pipes.

CORRESPONDENT, " F.S.," of Orpington, writes as follows :—I was very interested in your article on petrol pipes (issue January 11th) and should like to put forward my views on the matter. One can agree with your contributor that something more should be done to prevent the fracture of a length of copper tube holding up a valuable load.

The idea of an alloy for tubing that will stand vibration is good, as most of the trouble is caused through vibration hardening the tube, and it is useless to repair broken tubes unless these are softened at the same time, otherwise they are sure to break again before long.

Copper tube is softened by bringing to a red heat and cooling in cold water, exactly as one would harden steel.

The writer has had experience with steel pipes. and these stood up well on the particular make of lorry to which they were fitted.

Are there any makes of flexible pipe which will stand up to lorry work? The aeroplane makers have experimented with same, but I understand that they have gone back to copper tube with rubber inserted at intervals.

Stiffening the bottom of petrol tanks near the unions with pieces of angle brass, as supplied for footboard edging, has been found to cure some cases of petrol-pipe breakages.

There are three other unions in addition to those shown in your article, each of which the writer has found to reduce the trouble. In one the petrol pipe is swelled out to form its own nipple. This is used on a well-known lorry of British make. Another type was, no doubt, first fitted for cheapness, but it is very good, and has the advantage that should the pipe break near the union the driver can push it in and couple up again. This joint is simply a stuffing box with string packing. A type resembling this has a soft brass ring which is slipped on to the pipe and closed in petrol-tight the first time the union nut is screwed up. The brass ring cannot be removed again, but a joint is easily made with string, as described above, if necessary. An advantage these three joints have is that the same union nut and socket will do for each method, and a steel sleeve for extra support can be fitted if required.

Drilling on a Lathe.

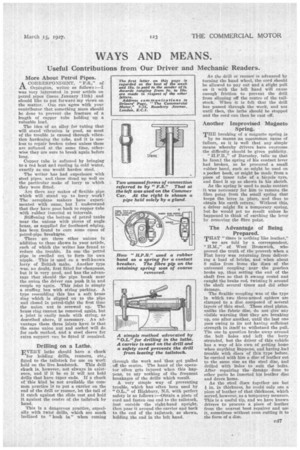

EVERY lathe should have a chuck

for holding drills, reamers, etc., fitted to the tailstock for use on work held on the live headstock. This drill chuck is, however, not always in existence, and if it be so it will not hold drills that have taper ends. If a chuck of this kind be not available the common practice is to put a carrier on the end of the drill or reamer, let the tail of it catch against the slide rest and hold it against the centre of the tailstock by hand.

This is a dangerous practice, especially with twist drills, which are much inclined to "hook in" when coming

through the work and thus get pulled . off the centre. The hand of the operator often gets injured when this happens, to say nothing of the frequent breakages of the drills which result.

A very simple way of preventing trouble, which has often been used by " 0.L.," of Highbury, N.5, with perfect safety is as follows :—Obtain a piece of cord and fasten one end to the tailstock, just outside the right-hand upright, then pass it around the carrier and back to the end of the tailstock, as shown, holding the end in the left hand. As the drill or reamer is advanced by turning the hand wheel, the cord should be allowed to pay out and a slight pull on it with the left hand will cause enough friction to prevent the drill from slipping off the centre of the tailstock. When it is felt that the driU has passed through the work, and not until then, the lathe should be stopped and the cord can then be cast off.

Another Improvised Magneto Spring.

THE breaking of a magneto spring is

by no means an tincommon cause of failure, so it is well that any simple means whereby drivers have overcome the difficulty should be given publicity.

" H.P.B.," of Barnsley, tells us that he found the spring of his contact lever had broken, so he procured a small rubber band, such as might be used on a pocket book, or might be made from a piece of inner tube of a bicycle tyre, and fixed it up as shown in his sketch.

As the spring is used to make contact it was necessary for him to remove the fibre point from the small spring that keeps the lever in place, and thus to obtain his earth return. Without this, a driver might fix a temporary spring, but -he would get no result unless he happened to think of earthing the lever by removing the fibre point.

The Advantage of Being Prepared.

THAT "there is nothing like leather,"

we are told by a correspondent, " H.M.," of West Bromwich, who proved the truth of the proverb when a Fiat lorry was returning from delivering a load of bricks, and when about 8 miles from home the discs of the universal coupling near the gearbox broke up, thus setting the end of the shaft free so that it swung round and caught the brake rod, twisting it around the shaft several times and did other damage.

The flexible coupling was of the type In which two three-armed spiders are clamped to a disc composed of several layers of thin steel. These steel plates, unlike the fabric disc, do not give' any visible warning that they are breaking up, one after another, until the last one goes owing to its not having sufficient strength in itself to withstand the pull. The one in question broke away around the bolt holes and left the lorry stranded, but the driver of this vehicle has a way of his own of getting home when anything happens, and having had trouble with discs of this type before, he carried with him a disc of leather cut to the same size as the steel disc, and drilled with holes to suit thel bolts. After repairing the damage done to other parts he inserted his leather disc and drove home.

As the steel discs together are but in. in thickness, he could only use a piece of leather of that thickness, which served, however, as a temporary measure. This is a useful tip, and we have known drivers to procure a piece of leather from the nearest boot repairer and use It, sometimes without even cutting it to the form of a disc.