IN THE WET

Page 60

Page 61

Page 62

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

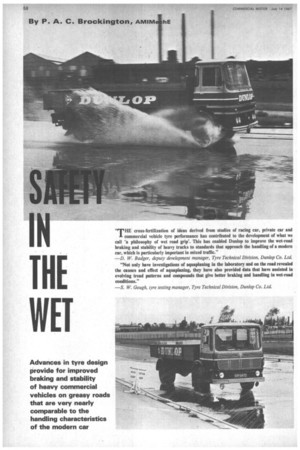

"Pr HE cross-fertilization of ideas derived from studies of racing car, private car and commercial vehicle tyre performance has contributed to the development of what we call 'a philosophy of wet road grip'. This has enabled Dunlop to improve the wet-road braking and stability of heavy trucks to standards that approach the handling of a modern car, which is particularly important in mixed traffic."

— D. W. Badger, deputy development manager, Tyre Technical Division, Dunlop Co. Ltd.

"Not only have investigations of aquaplaning in the laboratory and on the road revealed the causes and effect of aquaplaning, they have also provided data that have assisted in evolving tread patterns and compounds that give better braking and handling in wet-road conditions."

— S. W. Gough, tyre testing manager, Tyre Technical Division, Dunlop Co. Ltd.

During a roadside check of commercial vehicles by MoT examiners that I attended some years ago, the veteran driver of a 10-year-old eight-wheeler, whose vehicle could not be faulted, observed that "you can judge a vehicle and the operator by the tyres; if the tyres are good, the vehicle is good nine times out of 10 and it shows that the boss cares."

About a third of personal-injury accidents are caused by skidding on wet roads and it is reasonable to assume that a substantial proportion of these accidents result from the use of worn, ill-matched or unsuitable tyres, combined with a lack of knowledge by the driver of the hazards involved in emergency braking on wet surfaces.

Of the incompatibilities of heavy commercial vehicles with private cars, the most serious is the difference between braking efficiencies. But although the braking of a heavy lorry on a dry road is at best considerably less efficient than that of a wellmaintained private car, the difference in braking and handling in the wet creates the more serious hazards, despite the higher average skill of commercial vehicle drivers. Eliminate this difference and one of the most dangerous incompatibilities of mixed traffic is removed. The driver will then be able safely to utilize in the wet the dry-road braking efficiency that the new regulations require.

And it can be done, or very nearly, with the right tyres.

My request to Dunlop for information on the technicalities of recent tyre developments was prompted by an article in a Silverstone programme on the cornering power of racing cars by Charles Bulmer, editor of Motors writing on the all-important part that tyre improvements have played in reducing lap times. He pointed out that the latest racing tyres enabled the car to round a curve with a centrifugal acceleration of about 1.2 g.,

compared with an acceleration that could be achieved by a skilful driver of a private car of around 0.6 g.

A racing car is far removed from a heavy commercial vehicle in design and purpose, but surely there was a link, I considered, between the design (and development) of racing car and commercial vehicle tyres— with the private car in the middle somewhere. I went to Dunlop to find out.

In choosing compounds for the larger truck tyres special consideration has to be given to combining a high-grade property with cool-running characteristics which means that the compounds must have lowhysteresis losses. Fortunately tread pattern improvements have been the dominant contribution to progress in the truck tyre field and better wet-road grip has been achieved without a sacrifice of tread life.

First requirement

In the wet the first requirement is that the tread pattern should effectively wipe the road to give dry contact between rubber and road surface; then and only then can high grip tread compounds add to tyre safety. In the wet, the tread pattern is far more important than the properties of the compound with regard to anti-skid performance.

The most marked of the differences between the designs of racing car and commercial vehicle tyres is the size of the tyre section of the former compared with the latter and the relatively low pressure and loading of racing tyres. A large groundcontact area is an essential feature of the racing tyre in that it enables a higher-than-g centrifugal acceleration to be achieved (in the dry) by virtue of increased spragging action between tyre and road, which is a measure of the direct thrust derived from road surface irregularities.

It is pertinent to note that the latest Dunlop heavy truck tyre, the Highway 70, has a flat contact surface across the tread face, and of particular significance in the link between racing-car and truck tyre design is the common problem of maintaining road-surface contact of the tread in the wet, which necessitates getting rid of a very large volume of water at a very high rate from a large contact area.

Adhesion is reduced on a wet surface because water acts as a lubricant, and to obtain a grip at least part of the tread footprint must be wiped clean to give a dry road contact. If there is no dry contact the tyre can easily skid and may even aquaplane —when applying the brakes has no effect and lateral stability is completely lost without braking. Although aquaplaning with a smooth, tyre will not normally occur below 50 m.p.h. and a patterned tread will raise the critical aquaplaning speed to a value above the maximum speed normally attainable by a heavy truck, the study of aquaplaning has contributed to an important extent, as mentioned by Mr. S. W. Gough, to improving the braking and lateral adhesion of truck tyres.

The three-zone concept

In a paper presented at a meeting of the International Road Federation last year Mr. Badger and Dr. V. E. Gough (a brother of Mr. S. W. Gough) explained that the contact patch of a tyre on a wet surface can be divided into three zones. These are; the zone in which the water flow is unbroken; the wet-to-dry transition area; and the dry zone—which may in practice be only "substantially dry", in that globules of water are trapped in the tread slots or road cavities. These zones apply under any or all conditions, whether the tyre is rolling freely, being braked, cornering, or locked and skidding.

The relative proportions of these zones decide how much effective friction force the tyres can develop. Putting it very simply, friction is measured by relating the weight of an object to the force required to move it horizontally: for example, if a 11b. weight requires +lb. force to pull or push it along a surface, the frictional value is 0.5. In the case of the three zones, the first (unbroken water flow) has a friction of virtually nil, the third (dry zone) is nearly 1, while the transition zone provides an intermediate value dependent on a wide variety of factors. When a wheel equipped with a patterned tyre is locked at a very low speed, say 2 m.p.h., most of the water is expelled from the contact patch, and nearly the whole area is in dry contact with the road; in contrast, all the so-called contact area of an aquaplaning tyre is riding on an unbroken water film and there is no dry zone or measurable friction.

Squeezing out the water film takes time, and this explains the reduction in tyre friction as speed increases, depending on the extent of tread wear, the type of vehicle and the nature of the road surface.

The effectiveness of a tread pattern and high-grip compound in improving the peak braking efficiency obtainable in the wet is most marked in the case of a polished closetextured surface (which is relatively common and looks slippery) and tread patterns are least effective on what is known by the tyre technicians as a polished, smooth open macro-texture road surface, that is one that looks coarse from a distance but comprises highly-polished aggregate separated by grooves. These canal ways in the road retain water (unlike the grooves in tyre patterns) and feed the water into the contact patch.

The typical peak braking efficiency in the dry of a heavy truck in good mechanical condition is about 0.5/0.6 g., while a car can normally record an efficiency of 1.0 g. From 30 m.p.h., therefore, a car will stop in 32 ft. and a truck in 55 ft., the stopping distances from 50 m.p.h. being 88 ft. and 144 ft. respectively.

There are virtually no measures that tyre manufacturers can take to narrow this gap since retardation is governed by brake efficiency, the dry-road coefficient of a smooth tyre being as good if not slightly better than the coefficient of a patterned tyre. But they can close the gap between car and truck in wet-road conditions, which, as mentioned earlier, is far more important, notably because very few car drivers brake with an efficiency of more than 0.6 g. in the dry even in an emergency (at least at the start of art emergency) and the average commercial vehicle driver has a more highlydeveloped ability to anticipate a hazard. Moreover, the onset of instability or loss of control is much quicker if a vehicle is braked in an emergency in the wet.

Optimum stopping distance

Until recently, the optimum stopping distance of a truck when braked from 30 m.p.h. on a wet polished close-textured road surface was about 200 ft., representing a braking efficiency of 0.2 g., whereas a car can stop in 75 ft., the value for the truck being not far short of 300 per cent greater than the stopping distance for the car. have seen this demonstrated (from the passenger seat of the vehicle) on the proving ground at Fort Dunlop following an emergency crash stop by a Mini-Cooper from the same speed, all the wheels being locked on both vehicles. Although an improvement in efficiency could have been obtained by the skilled drivers of the vehicles by cadency braking, that is pumping the brake pedal to simulate the action of an anti-locking system such as the Dunlop Maxaret, full locking is necessary in such tests to enable accurate comparisons to be made.

With the latest type of truck tyre produced by Dunlop (the Highway 70) the stopping distance under the test conditions was reduced to 90 ft., representing an increase of only 20 per cent compared with the car. Over 80 per cent of the improvement achieved is derived from the type of tread pattern and the remainder to the high-grip polymer used in the production of the tread. The intensity of loading of a heavy truck tyre is about four times the loading of a car tyre or racing tyre and this exacerbates the problem of providing wet-grip without sacrificing rib stability under high cornering forces on dry roads. The series of tests on the Dunlop proving ground also included one in which two fully laden 16-tonners were driven on a wetted surface round a curve of 150 ft. radius which is similar to that of a typical traffic roundabout. Equipped with tyres having an obsolescent five-ribbed tread pattern, the first vehicle was driven into the curve at 26 m.p.h., skidded off-course, spun and finished up travelling backwards. Highway 70 tyres were fitted to the second vehicle and the curve was negotiated at 30 m.p.h. without deviation.

The extra channels of the Highway 70 provide for the bulk disposal of water from the flat-profile contact patch, while the rib section and the properties of the polymer ensure stability when the tyre is subjected to the high lateral forces created by dry-road cornering at speed. Having disposed of the main bulk of the water, when the vehicle is travelling on a wet surface, the problem remains of removing the vestiges of fluid between the tread rubber and the road surface over at least a substantial part of the contact patch to increase the area of dry contact. Moulded in the tread rubber across the ribs, over 1,000 knife slots in the Highway 70 sponge up the thin film of moisture remaining on the tread after the bulk of the water has been dispelled from the contact area to the grooves between the ribs, the total area of the slots being minimal compared with the total contact area.

Greater tread life

Dunlop claim that the improved grip of the Highway 70 has been combined with an increase of tread life of around 30 per cent (which has been confirmed by a number of operators) by virtue of the flat profile of the tread and the type of compound used. As with all types of tread, wet-road grip is reduced by wear, partly because the ability of the channels between the ribs to dispose of the bulk of the water is in part a function of their depth. Dunlop has recently published the results of its latest research into the relation between wet-grip and pattern wear on car tyres, and it is pertinent to record that when the tread pattern has been reduced to 2 m.m., the wet-grip is only about 35 per cent of that of a full-depth pattern in heavy rainstorm conditions (21 m.m. of water) at 70 m.p.h.

Because of its greater diameter and length of contact patch, the time that each part of a truck tyre is in useful contact with the road is about 0.010 sec. at 60 m.p.h. compared with 0.005/0.008 sec. in the case of a private car, but despite the much higher contact pressure of the truck-tyre tread, disposal of the bulk of the water is the more difficult, the increased water-flow distance being the main obstacle to water removal. With smooth tyres, disposal becomes impossible at around 50 m.p.h. and the tyres aquaplane—that is the tread is completely waterborne (without application of the brakes), the coefficient of friction is reduced to zero and the wheel comes to rest.

In a laboratory test in which the tyre is held in contact with the "road surface" of the revolving drum with the normal load, the tyre can be rotated by hand against the action of the drum, and on the road (as I observed as a passenger) the driver can spin the steering wheel to full lock in either direction with no deviation of the vehicle when the front wheels are aquaplaning. If the rear wheels aquaplaned, the vehicle would be completely unstable.

All grip is lost

When a tyre aquaplanes at 50 m.p.h. all grip is lost and grip is not restored until the speed of the vehicle has been reduced to 35 m.p.h. Dunlop contends that "few people live to talk about aquaplaning".

In simulation of steady rain conditions water is supplied to the drum surface at 10 gal./min. and the rate is then increased to 100 gal./min. to simulate a heavy rainstorm, which is sufficient to cause earlier types of tyre with a good tread to loose a considerable amount of grip at speeds of 60 m.p.h. or less. Even under rainstorm conditions, the Highway 70 provides a substantial grip at this speed.

Despite the advances that have been made in the disposal of water from a wide flat-profile tread, the increased flow path of a wide-single type of tyre is not conducive to rapid disposal, and wet-road adhesion of this type of tyre is reduced by some 20 per cent compared with twinned tyres. The gap between twinned tyres provides a good drainage channel. The wide single also compares unfavourably with twinned tyres with regard to wearing properties but has an advantage on loose surfaces by virtue of the degree of flotation it provides and offers a substantial reduction in weight.

Unwise to mix

It is emphasized by Dunlop that it is unwise to mix cross-ply and radial-ply tyres indiscriminately on a vehicle, notably on semi-trailer outfits, because of the difference in cornering power of the two types; while it is safe to fit cross-ply tyres to the front wheels of the tractive unit (which gives lighter steering) and radial-ply covers on the driving-axle wheels, interchanging the front and rear tyres would incur instability. Although tyres having improved adhesion properties cannot prevent jack-knifing, they reduce the tendency of an outfit to jack-knife.