Wreckers International

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

Europe's most established wrecker builders

The size of the loads being carried today, and frequently their hazardous contents, has brought about the need for the most sophisticated approach to what used to be a simple winch job. Certainly the design of recovery vehicles has undergone a complete transformation in the last ten years, so that now the average wrecker operator will turn out with a fast heavy vehicle equipped with twin boom lifting gear, nylon strop S; air cushions and all other necessary tackle to clear the road without further damaging the casualty or spilling its contents.

It is not generally appreciated what thought goes into the design of a wrecker in order to enable it to lift a 30 ton load directly back on to its wheels. The designer is first faced with the problem of selecting the right chassis and it is hard for the average operator to appreciate that the Wrecker shown below will out-perform in sheer lifting power the Wrecker shown above. It is all a question of balance.

A quick calculation of front axle weight, times wheelbase, divided by overhang, shows that when you add a second axle you virtually halve the performance. This has to be related to the stopping power of the wrecker which may have a dead weight of only 11 tons, but will be required to stop 32 tons hung behind it. As such, twin rear axles are vital for the necessary• road grip, so the designer has to strike a happy medium.

Today, because no 45 or 56 ton tractor units can be purchased in any other form, i.e. with wheelbase of say, 170in-190in, the only ideal wrecker chassis for the big wrecker operator is one of these tractors 'stretched' to the required wheelbase. Then he must decide whether he wants 4 or 6 wheel drive and, despite the fact that most wreckers today carry at least 200ft of cable, many still opt for all wheel traction. Completely losing sight of the fact that when a wrecker has a load . suspended on the back, the front axle weight is negligible, i.e. only 20% of its gross weight, and therefore has no grip anyway.

Once all these factors have been settled the basic outline of the ideal wrecker appears and then the choice of equipment is limited to either a twin winch unit or a hydraulic lift and tow unit Really it is plain common sense that if you are trying to lift a vehicle that has an overall length of, say, 40ft, it is logical that two winches must be used, otherwise twisting will take place. There are many occasions where a wrecker has to lift an overturned unit directly off the ground, which technically is impossible because if the winch cables are pulling horizontally then the casualty will merely shuffle towards the wrecker on its side.

It is at this point that the police send for a crane which usually means a wait of about four hours and a minimum lifting charge of six hours of the crane's hourly rate, which really is quite ludicrous.

There is much confusion between a purely teledraulic crane, such as Coles, the Army's recovery vehicle which has a single hydraulic boom, and a wrecker which frequently has no hydraulics, and on which the booms are of a fixed length and radius. Clearly there are many times when a crane is indispensibie, i.e. for trans-shipping loads or for lifting a loaded container completely clear of the ground for reshipment, but there is no case where cranes are necessary for carrying out road recovery, except for these reasons.

The Army's answer was to design and build a machine which incorporates all the advantages of a crane but which is legally allowed to tow casualties. Unfortunately, the power required to move such a giant machine puts it outside the scope of all ordinary operators. A frequent enquiry that the wrecker man receives is why not put hydraulic booms on the wrecker the same as on a crane.

The answer is that this technically turns the wrecker into a crane when it is subject to crane laws, i.e. 5:1 safety factor on wire ropes, safe load indicators, warning notices, etc., with none of which can the wrecker man comply because he can never weigh off his casualty because half of it is frequently on the ground when it is being lifted. The line of demarcation between the wrecker and the crane is becoming less clear as certain makes of hydraulic wrecker are sold which do extend under power and therefore can be said to be capable of luffing into danger or overload, and yet they are not fitted with the above safety devices. It was for all these reasons that Wreckers International first applied air cushions to road recovery, so that cranes or machines of that type are not required. An air cushion basically is a bag of wind which, when inflated to 7lbs psi and using about 75 cu ft of air, can actually lift a load of 6 tons vertically or lift and roll 10 tons. Combinations of these cushions can be built up to lift loads of up to 50/60 tons; indeed, the latest type will lift and roll 24 tons on its own. While they can be used to effect damage-free recovery, they are mainly used in order to lift the casualty the first 2ft off the ground, after which, Ift wide nylon strops are wrapped round the casualty and then the two winches of the wrecker complete the job.

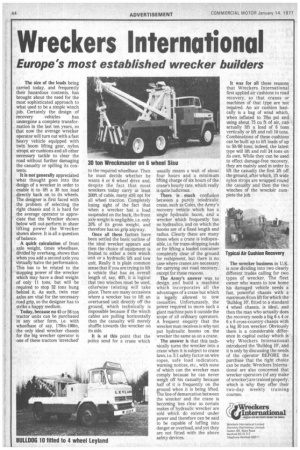

The wrecker business in U.K. is now dividing into two clearly different trades calling for two types of wrecker. The fleet owner who wants to tow home his damaged vehicle needs a fast, powerful chassis with a maximum 6 ton lift for which the 'Bulldog 10', fitted to a standard 4 wheel chassis, is ideal, and then the man who actually does the recovery needs a big 6 x 4 or 6 x 6 cross-country chassis with a big 30 ton wrecker. Obviously there is a considerable difference in capital outlay which is why Wreckers International introduced the 'Bulldog 10', and it is only by discussing the needs of the operator BEFORE the purchase that the right choice can be made. Wreckers International are also concerned that wrecker operators (of any make of wrecker) are trained properly, which is why they offer their two-day weekly training courses,