THE DESIGNER CAI iELP THE OPERATOR

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

IWAS interested to read Mr. J. Pickles' article, entitled " Can the Operator Help the Designer? ", in your issue dated October 15. He states that he is in sympathy with my more radical ideas on the subject of standardization, but fears, if he has interpreted me correctly, that standardization to the extent I have in mind is not entirely practicable. I welcome this opportunity of explaining in rather more detail my previous statements in your issue of September 24.

First of all let me say that it is nice to dismiss these matters with a designer. After all, he is one of those people whose co-operation and support are most essential. He is only the " boy in the back room." whom the users seldom, if ever, contact, and it was with this object that the Editor of " The Commercial Motor" called some of us together to see if some liaison could be effected. In setting out my ideas as to how far standardization should go, let me say, as a first stage at any rate, that it would be a great step in the right direction if designers would, as a preliminary move, conform to the I.A.E. standards which are published in collaboration between the" S.M.M.T and the I.A E., and issued to all manufacturers.

Brake and Clutch Disc Facings

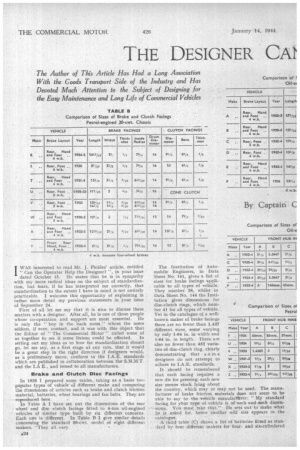

In 1935 I prepared some tables,, taking as a basis two popular types Of vehicle Oi different make and comparing the dimensions of articles such as brake and clutch friction material, batteries, wheel bearings and fan belts. They are reproduced here.

In Table A 1 have set out the dimensions of the rear wheel and disc clutch facings fitted to 6-ton oil-erq,Pined vehicles of similar type built, by six different concerns. Each one is different. In Table B I. give similar details concerning the standard 30-cwt. model of eight different makers. They all vary. The Institution of Automobile Engineers, in Data Sheet No. 141, gives a list of sizes for brake facings applicable to all types of vehicle. They number 26, whilst in Data Sheet No. 144 the Institution gives dimensions for disc-clutch rings, which number 41 for all types of vehicle. Yet in the catalogue of a wellknown maker of brake facings there are no fewer than 1,437 different sizes, some varying Make by only 1-64 in. in width and. 1-64 in. in length. There are also no fewer than 452 varieties of disc-clutch ring, clearly demonstrating that s o m e, designers do not attempt to adhere to I.A.E. standards.

It should be remembered that each facing requires a new die for pressing; each new size means stock lying about the country, which may or may not be used. The manufacturer of brake friction materials does not seem to be able to say to the -vehicle manufaettrer: " My standard facing for your type of vehicle is f.such and such dimensions. You must take that." -Ire sets out to make what he is asked for hence another odd size appears in the catalogue.

A third table (C). shows a list of batteries fitted as standard by four different makers for fourand six-cylindered oil engines. No two of them are the same size. Each different type of battery calls for fresh containers, fresh plates, new stamps and dies. large stocks • and storage accommodation, and, incidentally, higher prices. The battery maker blames the vehicle manufacturer and the latter the former. Meanwhile, the operator pays, whilst his vehicle may be rendered immobile awaiting the particular replacement battery which will fit into the battery box on his vehicle.

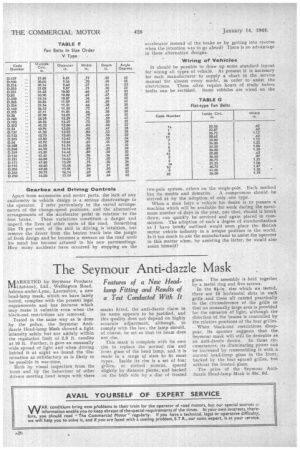

Table D concerns wheel bearings (taper-roller) fitted to 6-ton modern oil-engined vehicles. Here there are given five different types. None is interchangeable with any other. Millimetre dimensions are mixed up with inches. The same may be said of Table E, which deals with wheel bearings for six different makes of 30-cwt. chassis. Table F gives a list of fan belts of the -V type; and • Table. G of the-flat type---futther examples to confirm what I have already said, that standardization has been neglected to a serious degree, especially on component parts which the manufacturer does not usually produce himself. These, if purchased in larger quantities as standard parts, 9/54 13/16 48/64 286/64

1/8 1182 118

2.24

i/31 1/82 255/44 '11/16

would be more economical, could not in any way affect the efficiency of tb,e vehicle to which they were fitted, and wcluld greatly assist the maintenance problem and the keeping of an adequate supply of spare parts.

• The present system keeps a vehicle in the garage when it should be on the road. The stores may be full of parts% but the particular part required for a certain type of vehicle may be missing, and nothing else will do. Standardization of these components would ensure interchangeability between similar accessories used by different vehicle makers without restricting design or development. I have beard it said that " standardization may be desirable up to a point, but it can be carried to the stage at 'which it means stagnation of design." I do not think it can be claimed that any of my suggestions given so far need cause any-anxiety.

Make More Units Interchangeable

To proceed a stage farther, I do not think we should run any grave risks if gearboxes and their component parts were capable . of being transferred from vehicle to vehicle in the same classes. Back-axle shafts and rear drives could be similarly treated. There are far too many different types of wheel, tyre, wheel stud and rim. There are so many different types of rotor arm supplied for ignition sets that 'it was alleged that the complete security regulations in this country were-quite unnecessary provided that the rotor arm was removed from each. vehicle not in service, the argument being that if paratroops descended • here and wished to use a, vehicle they would have, to bring with them so many different types of rotor arm that they would not he in a pOsition to Carry . any . offensive equipment.

Gearbox and Driving Controls Apart from accessories and motor parts, the lack of any uniformity in vehicle design is a serious disadvantage to the operator. I refer particularly to the varied arrangements of the change-speed positions, and the alternative arrangements of the accelerator pedal in relation to the foot brake. These variations constitute a danger and imperil the lives of other users of the road. Something like 75 per cent, of the skill in driving is intuition, but remove the driver from the beaten track into the jungle of fresh design and he becomes a menace on the road until his mind has become attuned to his new surroundings. How many accidents have occurred by stepping on the accelerator instead of the brake or by getting into reverse when the intention was to go ahead? There is no advantage in these alternative designs.

Wiring of Vehicles It should be possible to draw up some standard layout for wiring all types of vehicle. At present it is necessary for each manufacturer to supply a chart in the service manual for almost every model, in order to assist the electricians. These often require hours of study before faults can be rectified. Some vehicles are wired on the two-pole system, others on the single-pole. Each method has its merits and demerits. A compromise should be arrived at by the adoption of only one type.

When a man buys a vehicle his desire is to possess a machine which will be available for work during the maximum number of days in the year, one that, should it break down, can quickly be serviced and again placed in commission. The adoption of such a degree of standardization as I have briefly outlined would soon place the British motor vehicle industry in a unique position in the world. Is it too much to ask the manufacturer to assist the operator in this matter when, by assisting the latter, he would also assist himself?