The Fawcett-Fowler Horizontal Engine.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

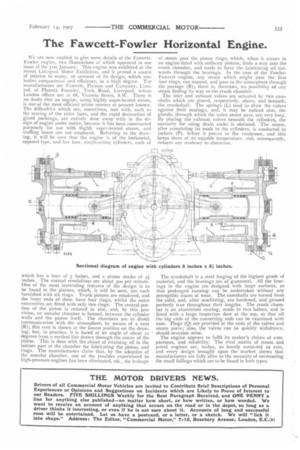

We are now enabled to give some details of the FawcettFowler engine, two illustrations of which appeared in our issue of the 31st January. This engine was exhibited at the recent Liverpool Motor Exhibition, and it proved a source of interest to many, on account of its design, which embodies compactness and efficiency, in a high degree. The manufacturers arc Fawcett, Preston and Company, Limited, of Phcenix Foundry, York Road, Liverpool, whose London offices are at 68, Victoria Street, S.W. There is no doubt that an engine, using highly super-heated steam, is one of the most efficient prime movers at present known. The difficulties which are, sometimes, met with, such as the scoring of the valve faces, and the rapid destruction of gland packings, are entirely done away with in the design of engine under notice, because it has been constructed purposely for use with highly super-heated steam, and stuffing boxes are not employed. Referring to the drawing, it will be seen that the engine is of the horizontal, opposed type, and has four, single-acting cylinders, each of which has a bore of 3 inches, and a piston stroke of 3i inches. The normal revolutions are about so° per minute. One of the most interesting features of the design is to be found in the pistons, which, it will be seen, are each furnished with six rings. Trunk pistons are employed, and the inner ends of these have four rings, whilst the outer extremities arc fitted with only two rings. The central portion of the piston is reduced in size, and, by this provision, an annular chamber is formed, between the cylinder walls and the piston itself. The chambers are in dirett communication with the atmosphere, by means of a vent (R); this vent is shown at the lowest position on the drawing, but, in practice., it is bored at an angle of about ett: degrees from a vertical line drawn through the centre of the piston. This is done with the object of retaining oil in the bottom part of the chamber for lubricating the piston, and rings. The manufacturers claim that, by the adoption of the annular chamber, one of the troubles experienced in high-pressure engines has been eliminated, via., the leakage of steam past the piston rings, which, when it occurs in an engine fitted with ordinary pistons, finds a way into the crank chamber, and tends to force the lubricating oil outwards through the bearings. In the case of the FowlerFawcett engine, any steam which might pass the first four rings, can expand, and pass to the atmosphere through the passage (R); there is, therefore, no possibility of any steam finding its way to the crank chamber.

The inlet and exhaust valves are actuated by two camshafts which are placed, respectively, above, and beneath, the crankshaft. The springs (L) tend to draw the valves against their seatings, and, it may be noticed also, the glands, through which the valve stems pass, are very long. By placing the exhaust valves beneath the cylinders, the necessity for using drain cocks is obviated. The steam, after completing its work in the cylinders, is conducted to jackets (P), before it passes to the condenser, and this keeps them at an equable temperature, and, consequently, reduces any tendency to distortion.

The crankshaft is a steel forging of the highest grade of material, and the bearings are of gunmetal. All the bearings in the engine are designed with large surfaces, so that prolonged running can be undertaken without any perceptible traces of wear. The camshafts are turned from the solid, and, after machining, are hardened, and ground perfectly true throughout their lengths. The crank chamber is an aluminium casting, made in two halves, and is fitted with a large inspection door at the top, so that all the big ends of the connecting rods can be examined with ease. Plugs (0) are provided at the ends of the valves and steam ports; also, the valves can be quickly withdrawn, should occasion arise.

The engine appears to fulfil its maker's claims of compactness, and reliability. The rival merits of steam and petrol engines are, to-day, as keenly contested as ever, and every design brought upon the market shows that manufacturers are fully alive to the necessity of overcoming the small failings which are to be found in both types.