Long-awaited light

Page 89

Page 90

Page 91

If you've noticed an error in this article please click here to report it so we can fix it.

van from Leyland by Graham Montgomerie BRITISH LEYLAND has announced a new range of light vans and deliveries designed and produced by the Austin Morris division to replace the longserving JU and J4 ranges. Designed under the code names CV306, the vehicles are now known by a type number rather than a name. Designated the Leyland 185, 215, 220, 240 and 250 models covering the 13 to 22 cwt nominal payload categories, the type number refers to the gvw — for example, the 250 has a gvw of 2.5 tons.

Design philosophy

In planning for the new range, a light commercial vehicle study group was set up by BLMC to analyse the type of vehicle required. This group included members from service, sales, finance, planning, engineering, etc, and from this combination 14 different configurations were investigated at the drawing board stage. Front-wheel drive, rear engine, forward control, normal control; all these and many others were considered until two final basic layouts were decided upon. These were normalcontrol vehicles with orthodox or frontwheel drive transmission lines. Leyland says that normal control was chosen because of the difficulty in meeting the safety requirements for impact with a forward-control design and obviously British Leyland could not bring in a new range which might not comply with possible future regulations.

Fleet owners and dealers who were consulted in the project stage said that they wanted accessibility and economy and were not particularly interested in new layouts for the sake of innovation — thus the CV306 was born on conventional lines.

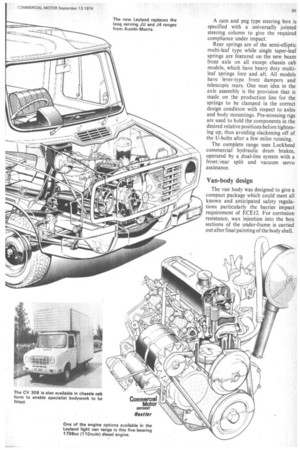

The integral-construction van is offered in three basic payloads and the chassis-cab models use the same basic mechanical units but have a separate channel-section parallel ladder frame to provide a basis for specialized bodywork.

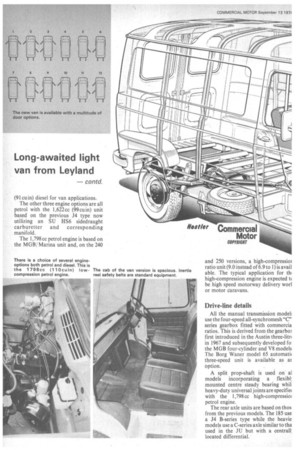

Power units

Four derivatives of the longestablished "B" series engines are used including a brand new 1,978 cc ' (110 min) five-bearing diesel engine which replaces the earlier 1,498 cc (91 Cu in) diesel for van applications.

The other three engine options are all petrol with the 1,622 cc (99 cuin) unit based on the previous J4 type now utilizing an SU HS6 sidedraught carburetter and corresponding manifold.

The 1,798 cc petrol engine is based on the MGB/ Marina unit and, on the 240 and 250 versions, a high-compressiol ratio unit (9.0 instead of 6.9 to 1) is avail able. The typical application for th high-compression engine is expected fi be high speed motorway delivery wonl or motor caravans.

Drive-line details

All the manual transmission model use the four-speed all-synchromesh "C" series gearbox fitted with commercia ratios. This is derived from the gearbo) first introduced in the Austin three-litp in 1967 and subsequently developed fo the MGB four-cylinder and V8 models The Borg Waner model 65 automati+ three-speed unit is available as at Option.

A split prop-shaft is used on al models incorporating a flexib1 mounted centre steady bearing whit heavy-duty universal joints are specifie with the 1,798 cc high-compressiol petrol engine.

The rear axle units are based on thos from the previous models. The 185 use a J4 B-series type while the heavie models use a C-series axle similar to tha used in the JU but with a centrall located differential. A cam and peg type steering box is specified with a universally jointed steering column to give the required compliance under impact.

Rear springs are of the semi-elliptic multi-leaf type while single taper-leaf springs are featured on the new beam front axle on all except chassis cab models, which have heavy duty multileaf springs fore and aft. All models have lever-type front dampers and telescopic rears. One neat idea in the axle assembly is the provision that is made on the . production line for the springs to be clamped in the correct design condition with respect to axles and body mountings. Pre-stressing rigs are used to hold the components in the desired relative positions before tightening up, thus avoiding slackening off of the U-bolts after a few miles running.

The complete range uses Lockheed commercial hydraulic drum brakes, operated by a dual-line system with a front/rear split and vacuum servo assistance.

Van-body design

The van body was designed to give a compact package which could meet all known and anticipated safety regulations particularly the barrier impact requirement of ECE12. For corrosion resistance, wax injection into the box sections of the under-frame is carried out after final painting of the body shell.