A Small Engine for Starting a Larger One

Page 154

If you've noticed an error in this article please click here to report it so we can fix it.

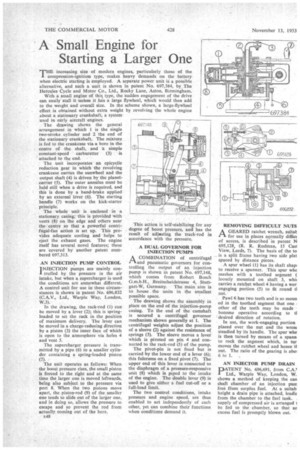

THE increasing size of modern engines, particularly those of the compression-ignition type, makes heavy demands on the battery when electric starting is employed. A separate power unit is a possible alternative, and such a unit is shown in patent No. 697,384, by The Hercules Cycle and Motor Co., Ltd., Rocky Lane, Aston, Birmingham, With a small engine of this type, the -sudden engagement of the drive can easily-stall it unless it has a large flywheel, which would then add to the weight and overall size. In the scheme shown, a large-flywheel effect is obtained without extra weight by revolving the whole engine about a stationary crankshaft, a system used in early aircraft engines.

The drawing shows the general arrangement in which 1 is the single two-stroke cylinder and 2 the end of the stationary crankshaft. The mixture is fed to the crankcase via a bore in the centre of the shaft, and a simple constant-speed carburetter (3) is attached to the end.

The . unit incorporates an epicyclic reduction gear in which the revolving crankcase carries the sunwheel and the output shaft (4) is driven by the planetcarrier (5). The outer annulus must be held still when a drive is required, and this is done by a band-brake applied by an external lever (6). The starting handle (7) works on the kick-starter principle.

The whole unit is enclosed in a. stationary easing;. this is provided with vents (8) on the edge and others near the centre so that a powerful centrifugal-fan action is set up. This provides adequate cooling and helps to eject the exhaust gases. The engine itself has several novel features; these are covered by another patent numbered 697,313,

AN INJECTION PUMP CONTROL INJECTION pumps are mainly con& trolled by the pressure in the air intake, but when a supercharger is used the conditions are somewhat different. A control unit for•use in these circumstances is shown in patent No. 696,832 (C.A.V., • Ltd., Warple Way, .London, W.3).

In the drawing, the rack-rod (1) can be moved by a lever (2); this is springloaded to set the rack in the position of maximum delivery. The lever can be moved in a charge-reducing direction by a piston (3) the inner face of which is open to the atmosphere via holes 4 and vent 5.

The supercharger pressure is transmitted by a pipe (6) to a smaller cylinder containing a spring-loaded piston (7). • The unit operates as follows: When the boost pressure rises, the small piston is forced to the right and at the same time the larger one is moved leftwards, being also subject to the pressure via port 8. When the two pistons move apart, the piston-rod (9) of the 'smaller one tends to slide out of the larger one, and in doing so, allows the pressure to escape and so prevent the rod from actually coming out of the bore.

e48 This action is Self-stabilizing for any degree of boost pressure, and has the result of acljasting the track-rod in accordance with the pressure.

A DUAL GOVERNOR. FOR INJECTION PUMPS

A COMBINATION of centrifugal £'L and pneumatic governors for controlling the output of an -injection pump is shown in patent No. 697,148, which comes from Robert Bosch G.m.b.H., Ereitscheidstrasse 4, Stuttgart-W, Germany. The main aim is to house the units in the smallest possible space.

The drawing shows the assembly in place on the end of the injection-pump casing. To the end of the camshaft is secured a centrifugal governor mechanism shown generally at 1. The centrifugal weights adjust the position of a sleeve (2) against the resistance of springs (3). The sleeve moves a lever which is pivoted on pin 4 and connected to the rack-rod (5) of the pump.

The pivot-pin is not fixed but is carried by the lower end of a lever (6); this fulcrums on a fixed pivot (7). The upper end of this lever is connected to the diaphragm of a pressure-responsive unit (8) which is piped to the intake of the engine. The double lever (9) is used to give either a fuel cut-off or a full-load limit.

The two control conditions, intake pressure and .,engine speed, are thus enabled to act independently of each other, yet can combine their functions when conditions demand it. REMOVING DIFFICULT NUTS

AGEARED ratchet wrench, suitat for use in places normally diffict of access, is described in patent N 695,128, (R. R. Rudman, 15 Cast View, Leeds, 7). The basis of the to is a split frame having two side plat spaced by distance pieces.

A spur wheel (1) has its shaft shapi to receive a spanner. This spur wise meshes with a toothed segment ( loosely mounzed on shaft 3, whi( carries a ratchet wheel 4 having a wor engaging portion (5) to fit round tl t.

Pawl 6 has two teeth and is so moun ed in the toothed segment that one other of the teeth may be made become operative according to d desired direction of rotation.

in use, the work-engaging portion placed over the nut and the wren( steadied by its handle. The spur whe is then turned by means of a spann to rock the segment which, in tur moves the ratchet wheel and hence ti nut. The ratio of the gearing is abol 6 to 1.

AN INJECTOR PUMP DRAIN DATENT No. 696,691, from C.A.' Ltd., Warpie Way, London, W. shows a method of keeping the can shaft chamber of an injection punt free ffom surplus fuel. At a suitab height a drain pipe is attached, leadir from the chamber to the fuel tank. supply of compressed air is arranged i be fed to the chamber, so that as excess fuel is promptly blown out.