Tyre Rotation Pays Off

Page 62

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

IEMPHASIZED last week the substantial reduction in tyre costs obtained by those operators who took the trouble to employ efficient systems of tyre maintenance and recording. The additional work necessary to inaugurate such schemes is more than justified by the ultimate savings, and a recommended tyre record form was detailed last week.

One form is made out for each cover as soon as it is issued, or where it is original equipment on a new vehicle. Subsequently, all positional changes throughout the life of the cover are recorded on this form, and total overall cost is proportioned directly in relation to the mileage run on the vehicles to which it may have been fitted.

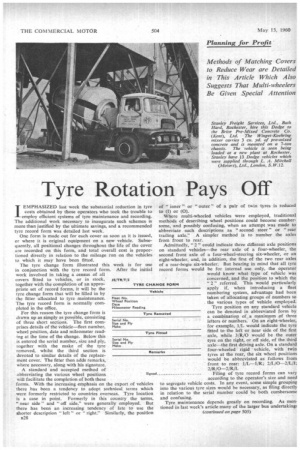

The tyre change form illustrated this week is for use in conjunction with the tyre record form. After the initial work involved in taking a census of all covers fitted to vehicles, or in stock, together with the completion of an appropriate set of record forms, it will be the tyre change form that will be filled in by

the fitter allocated to tyre maintenance. Fleet No.

JS/TRIT/2 Wheel

The tyre record form is normally cornDate Position Meted in the office. Mileometer Reading

For this reason the tyre change form is drawn up as simply as possible, consisting of three short sections. The first comprises details of the vehicle—fleet number, wheel position, date and mileometer reading at the time of the change. Below this is entered the serial number, size and ply, together with the make of the tyre removed, whilst the third section is devoted to similar details of the replacement cover. The fitter then adds remarks, where necessary, along with his signature.

A standard and accepted method of abbreviating the various wheel positions will facilitate the completion of both these forms. With the increasing emphasis on the export of vehicles there has been a tendency to adopt technical terms which were formerly restricted to countries overseas. Tyre location is a case in point. Formerly in this country the terms, "near side" and "off side," were generally employed. But there has been an increasing tendency of late to use the shorter description " left " or " right" Similarly, the position

Serial No. Size and Ply Make Serial No. Site and Ply Make Signed

of " inner ". or " outer " of a pair of twin tyres is reduced to (1) or (0).

Where multi-wheeled vehicles were employed, traditional methods of describing wheel positions could become cumbersome, and possibly confusing, when an attempt was made to abbreviate such descriptions as " second steer" or " rear trailing axle." A simpler method is to number the axles from front to rear.

Admittedly, " 2 " could indicate three different axle positions on standard vehicles—the rear axle of a four-wheeler, the second front axle of a four-wheel-steering six-wheeler, or an eight-wheeler, and, in addition, the first of the two rear axles of a rear-bogie six-wheeler. But bearing in mind that all tyre record forms would be for internal use only, the operator would know what type of vehicle was concerned, and the position to which the "2" referred. This would particularly apply if, when introducing a fleet numbering system, advantage had been taken of allocating groups of numbers to the various types of vehicle employed.

Tyre position on any standard vehicle can be denoted in abbreviated form by a combination of a maximum of three letters or numbers. On an eight-wheeler, for example, 1/1, would indicate the tyre fitted to the left or near side of the first axle, while 3/R/0 would be the outer tyre on the right, or off side, of the third axle—the first driving axle. On a standard four-wheeled rigid vehicle, with twin tyres at the rear, the six wheel positions would be abbreviated as follows from front to rear: 1/L-1/R; 2/L/0-211,/1; 2/R/0-2/R/I.

Filing of tyre record forms can vary according to the operator's size and need to segregate vehicle costs. In any event, some simple grouping into the various tyre sizes would be necessary, as filing directly in relation to the serial number could be both cumbersome and confusing.

Tyre maintenance depends greatly on recording. As mentioned in last week's article many of the larger bus undertakings (continued on page 505) pay for their tyres on a mileage basis. Tyre manufacturers provide staff solely responsible for the maintenance of tyres at many bus depots, each fitter being responsible for, say, 50 or 60 vehicles.

Whilst smaller passenger operators, as well as those engaged in haulage, may not be able to enter into a contract with a Lyre manufacturer for a similar scheme, it may prove of advantage to arrange for tyre maintenance to be done by•the.loeal agent or factor. As with .other services, the additional .7.ost, as compared with doing. one's own maintenance, would have to be met. But this might well be more than offset by the aving in the reduction of tyre stocks which could otherwise tecessitate asubstantial outlay by the operator. Moreover, that equipment was necessary for efficient tyre maintenance muld be comparatively little used when in the exclusive mploy of a small operator.

Neither the small nor even medium-sized operator would be ble to employ a fitter exclusively on tyre maintenance. As a .sult, whoever was so employed could not reasonably • be xpected to have the experience and skill of a fitter solely ngaged on tyre maintenance, who might well be able to btain substantially increased mileages by changing round at le appropriate time. His knowledge of the cause and effect

I exceptional tyre wear could also lead to the early remedy f mechanical defects on a vehicle. Such possible indirect wings in the overall operating cost of a vehicle should be iken into account when considering the cost of contracting 're maintenance to an agency or factor.

Regarding the location and rotation of tyres, the simplest sample of comparative wear would be on a small fourheeled vehicle, not fitted with twins. Assuming such factors

wheel alignment and weight distribution are correct, the ite of wear relative to the position would be expected to Inge from maximum to minimum as follows: 1/L, 1/R, 2/L, (R.

Thus, a new tyre would normally be fitted to the near-side -can wheel. Where it can be arranged, it is an advantage to fit DW tyres in the autumn or winter rather than in the spring r summer. This is because while a tyre is new and has maxiurn thickness, the amount of heat generated will be at a

maximum and would be raised by higher road temperatures in summer. The benefits of higher mileages and lower costs would

result if the tyres were fitted in the autumn or winter, with the additional advantage that the new tyre tread would be available when it was most needed.

. Systematic changing round is readily recognized as a basic factor in tyre maintenance, but the underlying principles and • the exact manner in which, this should be done, are less widely understood. The prime object is to equalize. as far as possible both the rate and type of wear which can be expected to occur in specific wheelpositions. On the small four-Wheeler just mentioned, for example, and assuming a spare tyre is available, the recommended method of rotation is as follows:-1/L to 2/L; 2/L to 1/R.; 1/R to. spare; spare to 2/R. Where an exper* eneed tyre fitter is available, his special • knowledge may justify tyfe changes being made on the basis of individual assessments of wear. Otherwise, the general principles applying to matching tyres on larger Vehicles would be of assistance in avoiding incorrect matching .and conse quential . -excessive wear. These vehicles could be grouped as follows:— (1) Sixor eightwheelers, with tandem rear axles.

on which only the leading axle of the' bogie is driven, (2) Sixor eight-wheelers, with tandem rear axles, both being driven, but with a third differential.

(3) Sixor eight-wheelers with tandem rear axles, both being driven, but with no third differential.

If the normal routine attention is given to the overall diameter of twins, vehicles in categories (1) and .(2) should not cause

undue • difficulties regarding tyre matching. Further improve ments may, however, be achieved by incorporating " the , suggestions recommended for vehicles in category (3) where this

is appropriate. Although differentials May have been included to balance up any variations in the comparative revolutions of each wheel, it is still undesirable to cause them to do unnecessary work because of .unequal tyre diameter.

For vehicles in category (3) special attention must be paid to the overall diameter of tyres fitted to each axle, although

it is realized that this is not always practicable. If Some compromise is inevitable—for example, when fitting four new and four part-worn covers—two new covers could be fitted to the near side of the first driving axle and a further two new covers to the off side of the second driving axle, with part-worn tyres in the two remaining positions, thus giving a diagonal fitment.

As an alternative, the four new covers could be fitted in the near-side position and all the part-worn to the off side. The object in both instances is to reduce the amount of work which the differential has to do in correcting overall revolutions.

If all the four new tyres had been fitted to one axle, and the remainder to the second axle, the two axles would clearly be revolving at different rates per mile. Two eventualities could then arise. Either there might be severe mechanical damage to the vehicle or excessive tyre wear might be caused through the slip necessary for the two axles to marry up their revolutions despite the variations in tyre diameters. &B.