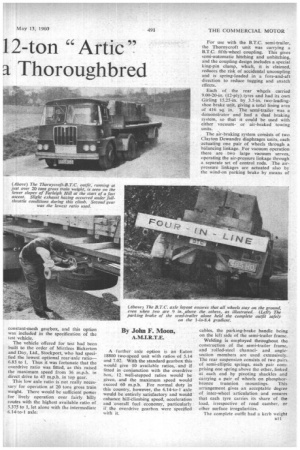

This is 12-ton " Artie " a Thoroughbred

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

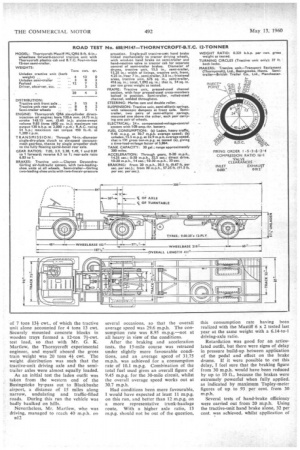

Thornycroft Tractive .Unit With B.T.C. Semi-trailer Shows Lively Performance with 12-ton Payload: 130-b.h.p. Engine Permits 20-ton Gross Weight Rating By John F. Moon,

AVARlATION of the Mastiff ML 18-ton-gross tractive unit is announced today by Transport Equipment (Thornycroft), Ltd., Basingstoke. The new vehicle has a gross train weight rating of 20 tons, permitting a clear 12-ton payload, This uprating is allowed because the QR6 130-b.h.p. oil engine—as used in Trusty models—is employed.

A road test of one of these models, hauling a B.T.C. 12-ton Four-in-line semi-trailer, showed it to have a particularly good performance, the high engine output making it easy to maintain fast average speeds over difficult country and through heavy traffic without marked detriment to fuel economy.

The new Mastiff follows the Thornycroft tradition in providing first-class driving conditions, and the recently introduced plastics cab, which incorporates a deep curved windscreen and paired headlamps, gives the tractor a distinctive and imposing appearance.

The ML/QR6 chassis is similar to the ML/NS6 18-ton-gross model except in respect of the power unit and gearbox. A wheelbase of 8 ft. 6 in. has been adopted in preference to a shorter dimension in the interests of providing reasonable riding characteristics, although these can never approach those of a tractive unit with a normal-control, longwheelbase layout. The QR6 power unit has a displacement of 9.83 litres, compared with the 7.88 litres of the 109-b.h.p. NS6 engine fitted in the standard Mastiff ML.

Thus, the new Mastiff tractive unit has the same power-to-weight ratio as the Mastiff MH/QR6 20-ton-gross six-wheeler (The Commercial Motor, November 6, 1959). The big difference between the rigid six-wheeler and the articulated version is that, because of the lower combined -unladen weight, the rigid model can carry a 14-ton payload, which is 2 tons more than could be handled by the tractive unit with the lightest of

semi-trailers without exceeding the legal 20-ton limit.

In view of the high engine power, however, I can see many operators using the ML/QR6 tractive unit at 24 tons gross weight with suitable tyres, even though this would exceed the manufacturers' maximum rating by 20 per cent, Certainly, the power is there to provide outstanding overall performance at this higher weight, as the QR6 engine is the standard unit for the Trusty 24-ton-gross' eight-wheeler.

As with the other Mastiff models, a Clayton Dewandre hydraulic steering servo is offered as an optional extra, but this was not fitted to the test vehicle. As the front axle loadingwas light (3 tons 154 cwt.), the absence of power assistance was no great disadvantage. Another optional extra is a sixth overdrive ratio for the standard five-speed constant-mesh gearbox, and this option was included in the specification of the test vehicle.

The vehicle offered for test had been built to the order of Mirrlees Bickerton and Day, Ltd., Stockport, who had specified the lowest optional rear-axle ratio6.83 to I. Thus it was fortunate that the overdrive ratio was fitted, as this raised the maximum speed from 36 m.p.h. in direct drive to 45 m.p.h. in top gear.

This low axle ratio is not really necessary for operation at 20 tons gross train weight. There would be sufficient power for lively operation over fairly hilly routes with the highest available ratio of 5.375 to 1, let alone with the intermediate 6.14-to-1 axle. A further axle option is an Eaton 18800 two-speed unit with ratios of 5.14 and 7.02. With the standard gearbox this would give 10 available ratios, and if. fitted in conjunction with the overdrive box, 12 well-stepped ratios would be given, and the maximum speed would exceed 60 m.p.h. For normal duty in this country, however, the 6.14-to-I axle would be entirely satisfactory and would enhance hill-climbing speed, acceleration and -overall fuel economy, particularly if the overdrive gearbox were specified with it.

For use with the B.T.C. semi-trailer, the Thornycroft unit was carrying a B.T.C. fifth-wheel coupling. This gives semi-automatic hitching and unhitching, and the coupling design includes a special king-pin clamp, which, it is claimed, reduces the risk of accidental uncoupling and is spring-loaded in a fore-and-aft direction to reduce tugging and snatch effects.

Each of the rear wheels carried 9:00-20-in. (12-ply) tyres and had its own Girling 15.25-in. by 3.5-in, two-leadingshoe brake unit, giving a total lining area of 416 sq. in. The semi-trailer was a demonstrator and had a dual braking system, so that it could be used with either vacuumor air-braked towing units.

The air-braking system consists of two Clayton Dewandre diaphragm units, each actuating one pair of wheels through a balancing linkage. For vacuum operation there are two large vacuum servos, operating the air-pressure linkage through a separate set of control rods. The airpressure linkages are actuated also by the wind-on parking brake by means of cables, the parking-brake handle being on the left side of the semi-trailer frame.

Welding is employed throughout the construction of the semi-trailer frame, and rolled-steel channeland anglesection members are used extensively. The rear suspension consists of two pairs of semi-elliptic springs, each pair comprising one spring above the other, linked at each end by pivoting shackles and carrying a pair of wheels on phosphorbronze trunnion mountings. This arrangement gives an acceptable degree of inter-wheel articulation and ensures that each tyre carries its share of the load, irrespective of road camber, or other surface irregularities.

The complete outfit had a kerb weight all of 7 tons 13+ cwt., of which the tractive unit alone accounted for 4 tons 13 cwt. Securely mounted concrete blocks in wooden trays formed a 12-ton 71-ewt. test load, so that with Mr. G. K. Martlew, the Thornycroft experimental engineer, and myself aboard the gross train weight was 20 tons 41 cwt. The weight distribution was such that the tractive-unit driving axle and the semitrailer axles were almost equally loaded.

As an initial test the laden outfit was taken from the western end of the Basingstoke by-pass out to Blackbushe airport, a distance of 15 miles along narrow, undulating and traffic-filled roads. During this run the vehicle was badly baulked on hills.

Nevertheless, Mr. Martlew, who was driving, managed to reach 40 m.p.h. on B12 several occasions, so that the overall average speed was 29.6 m.p.h. The consumption rate was 8.95 m.p.g.-not at all heavy in view of the conditions.

After the braking and acceleration tests, the 15-mile course was retraced under slightly more favourable conditions, and an average speed of 31.75 m.p.h. was achieved for a consumption rate of 10.1 m.p.g. Combination of the total fuel used gives an overall figure of 9.45 m.p.g. for the 30-mile circuit, whilst the overall average speed works out at 30.7 m.p.h.

Had conditions been more favourable, I would have expected at least 11 m.p.g. on this run, and better than 12 m.p.g. on a more representative trunk-haulage route. With a higher axle ratio, 13 m.p.g. should not be out of the question, this consumption rate having been realized with the Mastiff 6 x 2 tested last year at the same weight with a 6.14-to-1 driving-axle ratio.

Retardation was good for an articulated outfit, but there were signs of delay in pressure build-up between application of the pedal and effect on the brake drums. If it were possible to cut this delay, I feel sure that the braking figure from 30 m.p.h. would have been reduced by up to 10 ft., because the brakes were extremely powerful when fully applied, as indicated by maximum Tapley-meter figures of up to 93 per cent. from 30 m.p.h.

Several tests of hand-brake efficiency were carried out from 20 m.p.h. Using the tractive-unit hand brake alone, 32 per cent, was achieved, whilst application of the separate semi-trailer air-brake valve gave a meter reading of 31 per cent. A figure of 45 per cent. was then obtained by locking on the semi-trailer air valve and by pulling the tractive-unit hand brake on. These three separate tests showed that either or both of the hand controls provided useful emergency braking power.

Acceleration tests yielded good times up to 30 m.p.h. from standstill, using second, third, fourth and fifth gears. The maximum speeds in these ratios are 9.4 m.p.h., 15.5 m.p.h., 24.5 m.p.h. and 36.5 m.p.h. respectively.

Because of the low rear-axle ratio, firstrate direct-drive acceleration times between 10 m.p.h. and 30 m.p.h. were recorded, and the liveliness between 10 m.p.h. and 20 m.p.h. accentuates the good low-speed torque of the QR6 oil engine. It was possible to pull away without any engine or transmission roughness from as low a speed as 5 m.p.h. while in direct drive.

For the gradient tests Farleigh Hill was used. Ambient temperature was 64° F. The 'hill is 1.4 miles long and has an average gradient of 1 in 27. The ascent occupied 4 minutes 40 seconds, of which time 1 minute 5 seconds was spent in second gear running on the governor at about 9 m.p.h. While in this ratio slight hazing was noted at the outlet of the forward-mounted exhaust system.

The climb caused a rise in the coolant temperature of only 11° F., the final reading being 177° F., at which temperature the thermostat would be only about half open Thus, there is ample latitude in the cooling system for continuous climbing at low engine speeds in appreciably higher ambient temperatures, particularly as the cooling system is pressurized to 4 p.s.i.

Checking Fade Resistance

As a check for fade resistance I coasted the " artic " down this gradient, using the foot brake to keep the maximum speed to below 20 m.p.h. This descent lasted 3 minutes 22 seconds, and of this time 55 seconds were spent in direct drive with full throttle engaged so that the brakes were kept working on the less severe section of the hill towards the-bottom.

A " crash " stop gave a Tapley-meter reading of 68 per cent., which compares well with the average maximum meter reading of 82 per cent, obtained earlier in the day.

As the tractive unit had covered barely 500 miles before my test, its linings would

not be fully bedded-in. With a completely run-in vehicle, any appreciable amount of fade would be difficult to induce, as no driver under normal conditions would attempt a descent of a hill

like Farleigh in neutral. Smoke was issuing from the front brakes, but the remaining drums were relatively cool after this test.

Returning up the hill I stopped the outfit on the steepest section, the gradient of which is 1 in 8.4. The semi-trailer air brake alone held it easily on this slope, as did the separate parking brake when each was tried individually. With

both these brakes off I was able to prevent the outfit rolling backwards by using the tractive-unit hand brake, but only when I had applied this control with both hands.

A comfortable restart was made in second gear without slipping the clutch.

After these laden tests, an unladen fuel-consumption run was made over the 30-mile Basingstoke-Blackbushe course. The complete distance—which was covered in two legs—was run throughout in overdrive, including moving away from rest. The gross train weight at which this test was carried out was 7 tons 17 cwt., and the overall consumption rate was 15.5 m.p.g. for an average speed of 32.9 m.p.h. Thus, even under bad service conditions, 12-13 m.p.g. could be expected if the outfit had to work unladen in one direction.

While the test weights were off the semi-trailer I made timed uncoupling and reconnecting tests. Unhitching took only 1 minute 39 seconds, whilst recoupling required only 1 minute 27 seconds.

Raising Supporting Legs

These times included attending to the semi-trailer parking brake, lowering and raising the support legs, closing and opening the air-line cocks and breaking the air-line and electrical connections, releasing the king-pin jaws and driving the tractive unit clear of the semi-trailer.

I did not attempt normal maintenance tests, as, so far as the tractive unit is concerned, these would be almost identical to the procedures detailed in The Commercial Motor of ,September 12, 1958, when the Mastiff 4 x 2 vehicle was road tested. Maintenance of the semitrailer is mainly restricted to grease-gun lubrication of the Suspension and adjustment of the Girling brakes, each brake unit having a single square-headed adjuster.

The outfit handled well generally and the ride was good for a short-wheelbase tractor, special front-damper settings help ing appreciably in this respect. The frontaxle loading varies by less than 13 cwt. between the laden and unladen conditions, so the ride without payload was little different from that when carrying the 12-ton 71-cwt. test load.

While running unladen I safely made a "crash" stop from 20 m.p.h., although all four semi-trailer wheels and the driving-axle wheels locked. This test gave a Tapley-meter reading in excess of 100 per cent. Use of the semi-trailer-brake hand valve when empty is superfluous as the wheels immediately locked without noticeably slowing the outfit. The gearchange is as good as ever and clutchless changes could be made easily both up and down.

Stiff Because of Newness

Although the steering was not heavy, it appeared to be a little stiff, because of the newness of the chassis. No "tugging " of the semi-trailer was noticed on the road, but when taking sharp bends at reasonably high speeds, it seemed momentarily to take charge of the tractive unit.

This is a characteristic occasionally reported about articulated units and one often blamed for such outfits turning over at roundabouts and sharp corners. I had not come across it before, however, and it is possible that the condition was aggravated by the comparatively high centre of gravity of the test load. The relative positions of the coupling king-pin and tractive-unit rear axle might also be critical.

The standard cab is excellent in all respects, and two previous minor criticisms that I had of it have been met. The door-opening angle has now been increased to 90° and there are two grab handles at each side to aid entry into the cab.

A minor cab alteration for the customer consists of increasing the height of the radiator grille by 3 in. and lowering the bumper bar by 1 in. This is to accommodate an illuminated name box below the grille.