HINTS ON MAINTENANCE.

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

423.—The Care of the Friction Pump Drive on the Foden.

The friction drive used for the water pump on the Fotien wagon is a very satisfactory piece of mechanism if it be treated in a rational manner. Great care should always be taken of it, as it often has two jobs to perform, this being the case if the wagon is of the tipping type with an hydraulic ram. If slipping occurs the difficulty can be overcome by obtaining some resin and boiling this with a little cylinder oil until the resulting mixture can be plied out like a thin gum A small quantity of this mixture should be inserted into the grooves of the friction wheel, and it will then probably be found that the slipping has been entirely overcome. Instances have come to our notice where it has been unnecessary to adjust the friction discs for over three years. One reason for excessive wear is screwing down the gland nuts too tightly, as this makes the pump hard to work.

424.—Tightening the Axle Sleeves of a Garford

Chassis. ,

The rear axle casing of a worm-driven Garford chassis consists of a centre casting and two end castings, formed in one with each of'which is a sleeve which fits into one side of the centre casting, and is there pinned, as shown in the drawing. ..„ In one chassis these sleeves were such a slack fit in the centre casting that the retaining pins constantly became loose, or sheared right off, as a result of the vibration and the torque stresses on the axle.

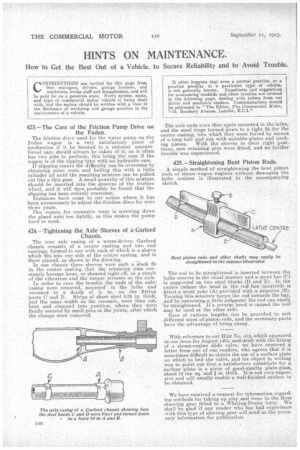

• In order to cure the trouble the ends of the axlecasing were removed, mounted in the lathe and

recessed to a depth of in. on the fitting "parts C and D. Strips of sheet steel 3-32 in. thick, and the same width as the recesses, were then cut, bent and clamped into position, where they were finally secured by small pins at the joints, after -which the clamps were removed.

The axle ends were then again mounted in the lathe, and the steel rings turned down to a tight fit for the centre casting, into which they were forced by means of a long bolt and nut with suitable plates and pack

ing pieces. With the sleeves in their right positions, new retaining pins were fitted, and no further trouble was experienced.

425.— Straightening Bent Piston Rods.

A simple method of straightening the bent piston rods of steam-wagon engines without damaging the lathe centres is illustrated in the accompanying Sketch.

The rod to be straightened is inserted between the lathe centres in-the usual manner and a stout bar (C) is supported on two steel blocks (D and E). In the centre (where the bend in the rod has occurred) is fitted a stout yoke (A) provided with a setscrew (B). Turning this setscrew forces the rod towards the bar, and by exercising a little judgment the rod can easily The straightened. If a reverse bend is caused the tool may be used at the other side.

Bars of various lengths c'an. be provided to suit different sizes of piston rods, and the necessary parts have the advantage of being cheap.

With reference to our Hint No. 412, which appeared in our issue for August 14th, and dealt with the fitting of a steam-engine slide valve, we have received a letter from one of our readers, who agrees that it is sometimes difficult to obtain the use of a surface plate on which to bed the valve, and his object in writing was to point out that, a satisfactory substitute for a surface plate is a piece of good-quality plate-glass, about 12 ins. sq. and f in. thiek. It-is not very expensive and will usually enable a well-finished surface to be obtained.

We have received a;request for information regarding methods for taking up play and wear in the Ross steering gear fitted to a Whiting-Denby lorry. We • shall be glad if any reader who has had experience with this type of steering gear will send us the necessary information for publication.