AN ENTIRELY NE EAM TRACTOR.

Page 18

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

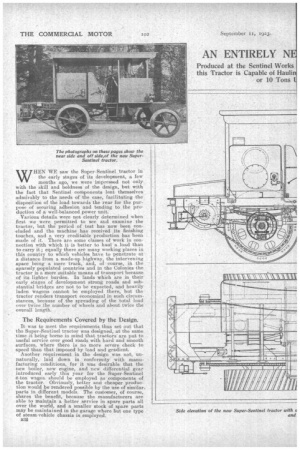

\W HEN WE saw the Super-Sentinel tractor in the ea a early stages of its development, few

months ago,we were impressed not only with the Skill and boldness of the design, but with the fact that Sentinel components lent themselves admirably to the needs of the case, facilitating the disposition of the load towards the rear for the purpose of securing adhesion and tending to the production of a well-balanced power unit.

Various details were not clearly determined when first we were permitted to see and examine the tractor, but the period of test has now been concluded and the machine has received its finishing touches, and a very creditable production has been made of it. There are some classes of work in connection with which it is better to haul a load than to carry it ; equally there are many working places in this country to which vehicles have to penetrate at a distance from a, made-up highway, the intervening space being a mere track, and, of course, in the• sparsely populated countries and in the Colonies the tractor is a more suitable means of transport because of its lighter burden. In lands which are in their early stages of develornment strong roads and substantial bridges are not to be expected, and heavily laden Wagons cannot be employed there, but the tractor renders transport economical in such circumstances, because of the spreading of the total load over twice the number of wheels and about twice the overall length.

The Requirements Covered by the Design.

It was to meet the requirements thus set out that the Super-Sentinel tractor was designed, at the same time it being borne in mind that tra.ctors'are put to useful service over good roads with hard and smooth surfaces, where there is no more severe check to speed than that imposed by load and gradient.

Another requirement in the design was not, unnaturally, laid down in conformity with manufacturing conditions, for it was desirable that the new boiler, new engine, and new differential gear introduced early this year for the Super-Sentinel a-ton wagon should be employed as components of the tractor. Obviously, better and cheaper production would be rendered possible by the use of similar, parts in •different models. The customer, of course, shares the benefit, because the manufacturers are able. to maintain a better, service in spare parts all over the world, and a smaller stock of spare parts may be maintained in the garage where but one type of steam-vehicle chassis is employed.

n32

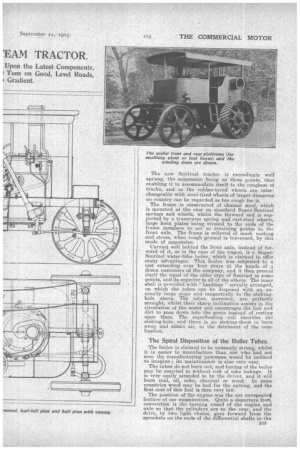

The new Sentinel tractor is exceedingly wellsprung, the suspension being on three points, thus enabling it to accommodate itself to the roughest of tracks, and as the rubber-tyred wheels are interchangeable with steel-tired wheels of larger diameter no country can be regarded as too rough for it.

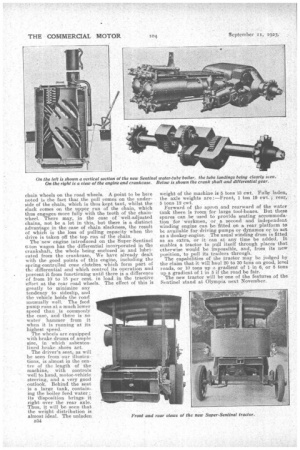

The frame is constructed of channel steel, which is mounted at the rear on standard Super-Sentinel springs and wheels, whilst the forward end is supported by a transverse spring and cast-steel wheels, large horn plates being riveted to the ends of the frame members to act as retaining guides to the front axle. The frame is relieved of much racking and stress, when rough ground is traversed, by this mode of suspension. Carried well behind the front axle, instead of forward of it, as in the case of the wagon, is a SuperSentinel water-tube boiler, which is claimed to offer many advantages. This boiler was subjected to a test extending over four years at the hands of a dozen customers of the company, arid it then proved itself the equal of the older type of Sentinel in some points, and its superior in all of the others. The inner shell is provided with "landings " spirally arranged, on which the tubes can be disposed with an_ unusually large slope and tangentially to the stokinghole above. The tubes, moreover, are perfectly straight, whilst their sharp inclination assists in the circulation of the water and encourages the fuel and dirt to pass down into the grate instead of resting upon them. The superheating coil encircles the stoking-hole, and there is no stoking-shoot to burn away and admit air, to the detriment of the combustion.

The Spiral Disposition of the Boiler Tubes.

The boiler is claimed to be unusually strong, whilst it is easier to manufacture than one who had not seen the manufacturing processes would be inclined to imagine ; its maintenance is also very easy.

The tubes do not burn out, and forcing of the boiler may be resorted to without risk of tube leakage. It is very easily attended to by the driver, and it will burn coal, oil, coke, charcoal or wood. In some countries wood may be had for the cutting, and the first cost of this fuel is then very Tow.

The position of the engine was the one unexpected feature of our examination. Quite a departure frort. convention is the turning round of the engine and axle so that the cylinders are to the rear, and the drive, by two light chains, goes forward from the sprockets on the ends of the differential shafts to the

chain wheels on the road wheels. A point to be here noted is the fact that the pull comes on the underside of the chain, which is thus kept taut, whilst the slack comes on the upper rim of the chain, which thus engages more fully with the teeth of the chainwheel. There may, in the case of well-adjusted chains, not be a lot in this, but there is a distinct advantage in the ease of chain slackness, the result or which is the loss of pulling capacity when the drive is taken off the top run of the chain.

The wheels are equipped with brake drums of ample size, in which asbestoslined brake shoes act.

The driver's seat, as will be seen from -our illustrations, is almost in the centre of the length of the machine, with controls well to hand, motor-vehicle steering, and a very good outlook. Behind the seat is a large tank, containing the boiler feed water ; its disposition brings it right over the rear axle. Thus, it will be seen that the weight distribution is almost ideal. The unladen 234 weight of the machine is 5 tons 13 cwt. Puny laden, the axle weights are :—Front, 1 ton 19 cwt. ; rear, 5 tons 12 cwt.

Forward. of the apron and rearward of the water tank there is room for large tool-boxes. But these spaces can be used to provide seating accommodation for 'workmen, oi. a second and independent winding engine can be fitted on a rear platform to be available for driving pumps or dynamos or to act as a donkey-engine. The usual winding drum is fitted as an extra, or it can at any time be added. It enables a tractor to pull itself through places that otherwise would be impossible, and, from its new position, to pull its trailers -through. The capabilities of the tractor may be judged by the claim that it will haul 20 to 30 tons on good, level roads, or 10 tons up a gradient of 1 in 6, or 8 tons up a gradient of 1 in 5 if the road be fair.

The new ttactor will be one of the features .01 the Sentinel stand at Olympia next. November.