ANEW POWER BRAKE

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

for Heavy Road Vehicles

ANOTICEABLE feature in modern designs of brake gear for heavy and fast-moving road machines is that engineers have had to emulate railway practice in several respects in order to obtain the high degree of power and responsiveness which road conditions now demand. Several eminent railway engineers in this country and abroad are now engaged in perfecting power brakes for commercial motors.

The Consolidated Brake and Equipment Co., Ltd., of Caxton Rouse, London, S.W.1, has just completed at its works at Slough tx.e final details of a new vacuum • system which incorporates a

• 3rage• reservoir that is capable of

energizing several applications cf the brakes, even if the vacuum supply be_ temporarily withdrawn. The arrangement is simple and robust, and in all circumstances the . braking efficiency is, to say the least, impressive.

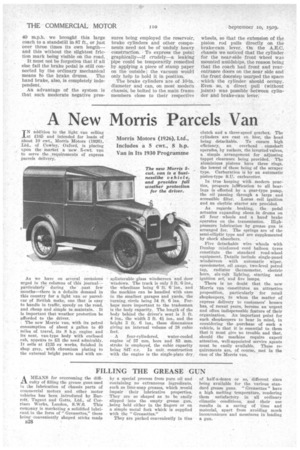

An A.E.C. Reliance saloon coach, to which the C.B.E. Uniped vacuumbrake, as the equipment is called, has been fitted, will this week be shown for the first time at the Conference of the Municipal. Tramways and Transport Association, which is being held at Great Yarmouth. Municipal engineers should not fail to examine it, remembering that it is suitable for both passenger and goods vehicles, and that chassis can be equipped without the necessity of any separate power take-off from the engine and without the complication of a compressor, with its high-pressure piping.

B26 The partial vacuum which exists • in the induction pipe of the petrol engine when the throttle is not widely open is made use of to ex haust air from a cylindrical reservoir of light steel construction which is suitably braced internally. In. the pipe connecting the induction vste.m with the reservoir there is a simple non-return valve of the type in which a ball is lifted by the suction and falls by gravity into the closed position, even if there be no exhaust pressure on the reservoir side. We mention this point because the absence of any spring in this valve is a good feature, the valve being practically incapable of getting out of order.

The reservoir referred to is connected by a pipe to the Unipet1 patent control valve. Actuation of -the latter by means of the brake pedal opens passages between the reservoir and four brake cylinders, one of which operates on the brake drum of each road wheel. Needless to say, for six-wheeled vehicles six cylinders can, if necessary, be fitted.

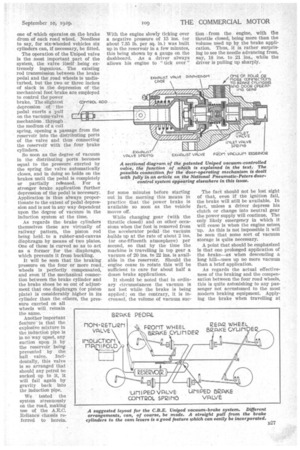

The operation of the Uniped valve is the most important part of the system, the valve itself being extremely ingenious. The existing rod transmission between the brake pedal and the road wheels is undisturbed, but the two or three inches of slack in the depression of the mechanical foot brake are employed to control the power brake. The slightest depression of the pedal exerts a pullon the vacuum-valve mechanism . through the medium of a coil

spring, opening a passage from the reservoir into the distributing ports of the valve and thus connecting the reservoir with the four brake cylinders.

So soon as the degree of vacuum in the distributing ports becomes equal to the pressure exerted by the spring the valve automatically closes, and in doing so holds on the brakes until the pedal is completely or partially released. For a stronger brake application further depression of the pedal is necessary.

Application is thus always proportionate to the extent of pedal depres sion and is not in any way dependent upon the degree of vacuum in the induction system at the time.

As regards the brake cylinders themselves these are virtually of railway* pattern, the piston rod being held, to a rubber-and-canvas diaphragm by means of two plates.

One of these is curved so as to act as a former for the diaphragm, which prevents it from buckling.

It will be seen that the braking pressure on the four or more road_ wheels is perfectly compensated, and even if the mechanical connec tion between the brake cylinder and the brake shoes be so out of adjustment that one diaphragm (or piston plate) is considerably higher in its cylinder than the others, the pressure exerted on all wheels will remain the same.

Another important feature • is that the explosive mixture in the induction pipe is in no way upset, any suction •upon it by the reservoir being prevented by the ball valve. Incidentally, this valve is so arranged that should any petrol be sucked up to it, it will fall again by gravity back into the induction pipe. We tested the system strenuously on the road, making use of the A.E.C. Reliance chassis referred to herein. With the engine slowly ticking over a negative pressure of 15 ins. (or about 7.35 lb. per sq. in.) was built up in the reservoir in a few minutes, this being shown by a gauge on the dashboard. As a driver always allows his engine to "tick over ",

for some minutes before starting out in the morning this means in practice that the power brake is available so soon as the vehicle moves off.

While changing gear (with the throttle closed) and on other occasions when the foot is removed from the accelerator pedal the vacuum builds up at the rate of abdut 2 ins. (or one-fifteenth atmosphere) per second, so that by the time the machine is travelling in top gear a vacuum of 20 ins. to 22 ins, is available in the reservoir. Should the engine cease to rotate this will he sufficient to care for about half a dozen brake applications.

It should be noted that in ordinary circumstances the vacuum is not lost while the brake is being applied ; on the contrary, it is increased, the volume of vacuum suc lion from the engine, with the throttle closed, being more than the volume used up by the brake application. Thus, it is rather surprising to see the needle advancing from, say, 18 ins. to 21 ins., while the driver is pulling up sharply.

The fact should not be lost sight of that, even if the ignition fail, the brake will still be available. In fact, unless a driver depress his clutch or change into neutral gear the power supply will continue. The only likely emergency in which it will cease is when the engine seizes up. As this is not impossible it will he seen that some sort of vacuum storage is quite necessary.

A point that should be emphasized is that one prolonged application of the brake—as when descending a long hill—uses up no more vacuum than a brief application.

As regards the actual effectiveness of the braking and the compensation between the four road wheels, this is quite astonishing to any passenger not accustomed to the most modern braking equipment. Applying the brake when travelling at

40 m.p.h, we brought this large coach to a standstill in 87 ft. or just over three times its own length— and this without the slightest friction mark being visible on the road.

It must not be forgotten that if all else fail the brake pedal is still 6mnected by the ordinary mechanical means to the brake drums. The hand brake, also, is completely independent.

An advantage of the system is that such moderate negative pres cures being employed the reservoir, brake cylinders and other components need not be of unduly heavy construction. To express the point graphically—if crudely—a leaking pipe could be temporarily remedied by applying a piece of stamp paper on the outside; the vacuum would only help to hold it in position.

The brake cylinders are of 10-in. diameter and can, on most modern chassis, be bolted to the main frame members close to their respective wheels, so that the extension of the piston rod pulls directly on the brake-cam lever. On the A.E.C. chassis we noticed that the cylinder for the near-side front wheel was mounted amidships, the reason being that the coach had front and rearentrance doors on the near side and the front doorstep usurped the space which the cylinder should occupy. Even so, a direct pull (without joints) was possible between cylinder and brake-cam lever.