The MUNICIPAL VEHICLE

Page 78

Page 79

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

r WANT

By S. J. Burn,

A.M.I.R.T.E., A.M.I.T.A., A.M.A.S.E.E. IN the municipal field, as . in commercial transport undertakings, transport engineers vary in their preferences for one vehicle design as opposed to others. Without this difference of opinion there would be little progress, and, provided that criticism is constructive, it is good.

I would suggest, however, that all municipal transport engineers share the view that mechanical road sweepers and refuse-collecting vehicles are necessarily expensive units of equipment, as they are constantly in service, carrying heavy loads of abrasive materials, which play havoc with the mechanism in general In view of the nature of the work, bodywork and tyres often suffer abuse and unless strict maintenance and regular docking programmes are carried out, the vehicles will rapidly deteriorate and the annual maintenance estimates will become quickly overspent.

The current design of gully and cesspool-emptier, is of a high standard, and, in general, is first class for the work it has to do. In recent years many improvements have been made in these machines to bring them up to their present efficiency. Bearing in mind the trend towards improved drainage systems throughout the country, the vehicles now in use are probably of adequate capacity, particularly remembering the need to ensure ease of manceuvrability. .

. " Many Face-lifts

, But I believe that .too many years have been spent in using the present design of mechanical sweeper. It is true that many face-lifts have been given to these machines; but, in numerous instances, the trailing of road silt is still visible. It may be argued that brush pressures are incorrect, brushes are unevenly worn or adjustments are incorrect. My criticisms are, however, based on tests of new vehicles with new brushes, and all adjustments carried out by the manufacturers, and they lead to the conclusion that the present type of road-sweeping machine cannot achieve the high standard expected in this modern age.. An improved form of equipment is overdue and the aim should be to secure a 7-ft. width of sweep with suction assistance. . ' ' What about cleaning highways during the leafing period, when leaves can be found impacted to road surfaces after rainfall? This, in itself, creates no problem whatsoever, so long as the correct technique is employed in the design of the machine. How can the noise of the fan unit be counteracted? This, again, is not so difficult to eliminate, and can be achieved well within the official regulations laid down.

All who operate mechanical road sweepers appreciate the heavy expenditure incurred annually on maintenance and the time expended in carrying out brush changes, which indicates the need for automatic lubrication of 'chassis components and brush gear.

have in mind a mechanical . sweeper in which the change of brushes would be so simplified that the operation could be effected in a matter of minutes, and the daily greasing could be reduced to a minimum by the incorpora tion of automatic lubrication.

Many local authorities who operate mechanical sweepers find it essential to augment this service by manual sweeping. This, in itself, entails the further use of vehicles for scavenging purposes (collecting bulk sweepings from the manual sweepers' beats).

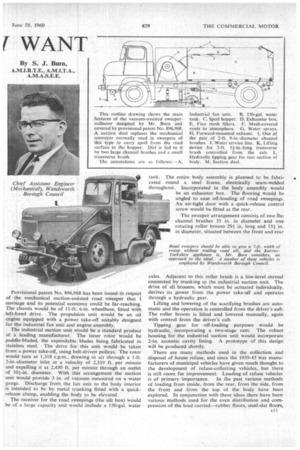

Provisional patent No. 896,968 has been issued in respect of the mechanical suction-assisted road sweeper that I envisage and its potential economy could be far-reaching. The chassis would be of 11-ft. 6-in, wheelbase, fitted with left-hand drive. The propulsion unit would be an oil • engine equipped with a power •take-off suitably designed for the industrial fan unit and engine assembly.

• The industrial suction unit would be a standard product of a leading manufacturer. The inner rotor would be paddle-bladed, the expendable blades being fabricated in stainless steel. The drive for this unit would be taken from a power take-off, using belt-driven pulleys. The rotor would turn at 1,318 r.p.m., drawing in air through a 1-ft. 2-in.-diameter inlet at a velocity of 2,319 ft. per minute and expelling it at 2,450 ft. per minute through an outlet of 101-in. diameter. With this arrangement the suction unit would provide 3 in. of vacuum measured on a water gauge. Discharge from the fan unit -to the body interior is intended to be by metal trunking fitted with a quickrelease clamp, enabling the body to be elevated.

The receiver for the road sweepings (the silt box) would be of a large capacity and would include a 150-gal. water

tank. The entire body assembly is planned to be fabricated round a steel frame, electrically seam-welded throughout. Incorporated in the body assembly would be an exhauster box. The flooring would be angled to ease off-loading of road sweepings. An air-tight door with a quick-release control crew would be fitted at the rear.

The sweeper arrangement consists of two flat channel brushes 33 in. in diameter and one rotating roller broom 29-1 in. long and 154 in. in diameter, situated between the front and rear axles. Adjacent to this roller brush is a low-level shroud connected by.trunking to the industrial suction unit. The drive of all brooms, which must be actuated individually, derives its power from the power lake-off and operates through a hydraulic gear.

Lifting and lowering of the scarifying brushes are automatic and the operation is controlled from the driver's cab. The roller broom is lifted and lowered manually, again with control from the driver's cab.

Tipping gear for off-loading purposes would be hydraulic, incorporating a two-stage ram. The robust housing for the industrial suction unit would incorporate 2-in, acoustic cavity fining. A prototype of this design will be produced shortly.

There are many methods used in the collection and disposal of house refuse, and since the 1939-45 war manufacturers of municipal vehicles have given much thought to the development of refuse-collecting vehicles, but there is still room for improvement. Loading of refuse vehicles is of primary importance. In the past various methods of loading from inside, from the rear, from the side, from the -front and from the top of the body have been explored. In conjunction with these ideas there have been various methods used for the even distribution and compression.of the load carried—rubber floors, steel-slat floors,

compression barriers, barrier loaders, compression by its own weight, by the use of fore-and-aft tippers, and compression by the screw impeller, as originally practised on the Continent.

In my opinion, the Continental countries have shown much more interest in the development of refuse vehicles than we in Britain. During a visit to Germany in 1959, I was much impressed by the ease of collection of house refuse, the cleanliness of the loading operation and, in particular, the co-operation received from the public.

, This was not an isolated case of efficiency, put on for the benefit of the visitor. I inspected six other systems without the authorities responsible being aware of it. An important factor must be stressed. If the refuse-collecting service in this country is to reach the required standard of efficiency, the co-operation of the public is essential.

• Six Fundamentals

There are at least six fundamentals which must be taken into account when designing a refuse-collecting vehicle: (1) To ensure an economic payload the body must be of 30-35-cu.-yd. capacity.

(2) Isolation of mechanical moving parts from refuse content.

(3) Low loading line.

(4) Choice of propulsion unit, paying special attention • to the engine cooling system, in view of the constant stopping and starting and use of low gears. In my view, the best type of engine for this work would be the aircooled diesel.

(5) Ease of vehicle maintenance, introducing automatic lubrication.

(6) Adequate travelling accommodation for the crew.

In my opinion, the great Majority of local authorities employ outdated methods of loading vehicles and the day is rapidly approaching when councils will be compelled by public demand to adopt more hygienic systems of collection.

One of the objections to the moving floor (whether of steel slats or rubber) is the increased loading line which

has to be allowed for under the floor mechanism controlling the moving of the floor itself, which means that steps must be fitted to the rear of the vehicle. With the barrier loader, whilst the height of the movable barrier can be• adjusted, the men are required to mount steps to enter the vehicle to tip the bin, which is regarded as unhygienic.

Dustless loading is much employed on the Continent, even by the smallest authorities, despite the heavy capital expenditure incurred in the purchase of good vehicles and equipment.

Substantial Outlay

In West Germany the purchase price of a 20-cu.-yd. refuse-collecting vehicle was given as D,M.57,740, equivalent to £4,930, plus hydraulic bin-lifting attachment at a cost of £344 and automatic dustless-loading gear at £308, making a total of £5,582 in English currency. In addition. this system involves substantial outlay in the purchase of heavy-gauge bins for each household. The receptacle takes the form of a fabrication with a hinged lid and must be of standard specification to suit the system adopted by the authority. . In many instances the bin is supplied to the householder on a rental basis which is equivalent in our currency to 111d. per week.

The number of local authorities who are introducing dustless loading is• steadily increasing, because of hygienic necessity and public demand, even though heavy expenditure must be incurred in the purchase of vehicles and equipment, and despite the fact that the rate of dustless loading of vehicles is probably lower than that ,Of.,.other types of refuse vehicle.

The increasing number of high-density multi-storey flats now being built will influence the type of vehicle to be used in the future upon collection of refuse from these dwellings. I look forward to the production of a specialized refuse vehicle incorporating the principle of high vacuum combined with a disintegrator to obviate the exposure of the refuse to the air and ensure a complete load. This is not beyond the realms of possibility when it is remembered that commerce is using the same principle for loading and discharging certain bulk commodities.