An Eighty-five cwt. Napier Chassis.

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

Nominally a 51.-ton Commercial Vehicle, this Chassis will Support a Gross Load of 85 cwt., Including the Weight of Body, Fittings and Driver.

The chassis which we are about to describe cannot, correctly speaking, be termed a new model. It was first referred to in our issue dated 3rd July, 1913, the short description which we then published being the first public refer

ence thereto. Since then, natui• ally, sundry improvements in detail have suggested themselves to the makers, and it occurred to us that some further reference would, on that account, if not on any other, be interesting to our readers.

Immediate Delivery Impossible. At the present time the delivery of this model, in company with practically the whole of Napier productions, is confined to the War Office, and, as a consequence, the ordinary purchaser is not able to obtain any definite delivery dates. At the same time, it should not be oNerlooked that " first come, first served," and those who aredesirous of becoming possessed of one of these chassis at an early date should lose no time in having their na.mo plated in turn on the waiting

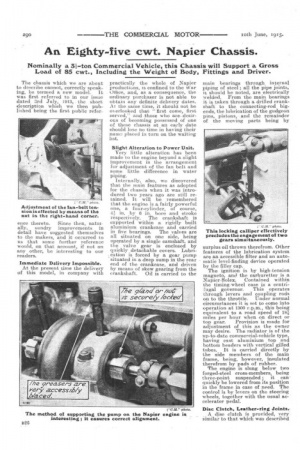

Slight Alteration to Power Unit. Very little alteration has been made to the engine beyond a slight improvement in the arrangement for adjustment of the fan belt and some little difference in water Internally, also, we discovered that the main features as adopted for the chassis when it was introduced two years ago are still retained. It will be remembered that the engine is a fairly powerful one, a four-cylinder, of course, 4,; in. by 6 in. bore and stroke respectively. The crankshaft is supported within a rigidly built aluminium crankcase and carried in five bearings. The valves are all situated on one side, being operated by a single camshaft, and the valve gear is enclosed by quickly detachable covers. Lubrication is forced by a gear pump 'situated in a deep sump in the rear end of the crankcase, and driven by means of skew gearing from the

crankshaft. Oil is carried to the main bearings through internal piping of steel ; all the pipe joints, it should be noted, are electrically welded. From the main bearings it is taken through a drilled crankshaft to the connecting-rod bigends, the lubrication of the gudgeon pins, pistons, and the remainder of the moving parts being by surplus oil thrown therefrom. Other features of the lubrication system are an accessible filter and an automatic level-finding device operated by the filler cap. The ignition is by high-tension magneto, and the carburetter is a Napier-Solex. Contained within the timing-wheel case is a centrifugal governor. This operates through levers and coupling rods on to the throttle. Under normal circumstances it is set to come into operation at 1300 r.p.m., this being equivalent to a road speed of 181 miles per hour when on direct or top gear. Provision is made for adjustment of this as the owner may desire. The radiator is of the up-to-date commercial-vehicle type, having cast aluminium top and bottom headers with vertical gilled tubes. It is carried directly by the side members of the main frame, being, however, insulated therefrom by pads of rubber.

The engine is slung below two forged-steel cross-members, being three-point suspended it can quickly be lowered from its position in the frame in case of need. The control is by levers on the steering wheels, together with the usual accelerator pedal.

Disc Clutch, Leather-ring Joints.,

• A disc clutch is provided, very similar to that which was described a few weeks ago in reference to the 45-ewt. model. It may be remembered that this consists of a steel disc between two others which are lined with Ferodo, and that in its design is incorporated a very simple and effective means of adjustment. The clutch is coupled to the gearbox shaft by means of a doubly articulated shaft, the universal joints of.which are of the leather-disc type. The whole of the clutch is enclosed by a light, sheetsteel cover, in halves, and arranged to be readily removable when accetss is desired to the mechanism.

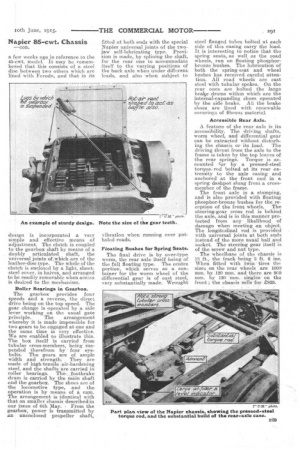

Roller Bearings in Gearbox.

The gearbox provides four speeds and a reverse, the direct drive being on the top speed. The gear change is operated by a side lever working, on the usual gate principle. The arrangement whereby it is made impossible for two gears to be engaged at one and the same time is very effective. We are enabled to illustrate this. The box itself is harried from tubular cross-members, being suspended therefrom by four eyebolts. The gears are of ample width and strength. They are made of high-tensile air-hardening steel, and the shafts are carried in roller bearings. The. footbrake drum is carried by the maul shaft and the gearbox. The shoes are of the locomotive type, and the operation is by means of a cam. The arrangement is identical with that on smaller chassis described in our issue of 6th May. From the gearbox, power is transmitted by unenclosed propeller shaft, fitted at both ends with the special Napier universal joints of the twojaw self-lubricating type. Provi s i ion s made, by splining the shaft, for the rear one to accommodate itself to the varying positions of the back axle when under different loads, and also When subject to vibration when running over potholed roads.

Floating Bushes for Spring Seats.

The final drive is by over-type worm, the rear axle itself being of the full floating type. The centre portion, which serves as a container for the worm wheel of the differential gear is of cast steel, very substantially made. Wrought

steel flanged tubes bolted at each side of this casing carry the load. It is interesting to notice that the spring seats, as well as the road wheels, run on floating phosphorbronze bushes. The lubrication of both the spring-seat and wheel bushes has received careful attention. All road wheels are cast steel with tubular spokes. On the rear ones are bolted the large bralse drums within which are the internal-expanding shoes operated by the side brake. All the brake shoes are lined with renewable coverings of fibrous material.

Accessible Rear Axle.

A feature of the rear axle is its accessibility. The driving shafts, worm wheel, and differential gear can be extracted without disturbing the chassis or its load. The driving thrust from the axle to the i frame s taken by the top leaves of the rear springs. Torque is accounted tor by a pressed-steel torque rod bolted at its rear extremity to the axle casing and anchored at the -front end in a spring dashpot slung from a crossmember of the frame.

The front axle is a stamping, and is also provided with floating phosphor-bronze bushes for the reception of the front wheels. The steering-gear cross rod is behind the axle, and is in this manner protected from any likelihood of damage when meeting an object. The longitudinal rod is provided with universal joints at both ends instead of the more usual ball and socket. The steering gear itself is of the screw and nut type.

The wheelbase of the chassis is 73 ft., the irackbeing 5 ft. 6 ins. When fitted with 'Win: tires the sizes on the rear wheels are 1000 mm. by 120 mm. and there are 900 mm. by 120 'ram. singles on the front ; the chassis sells for 2825.