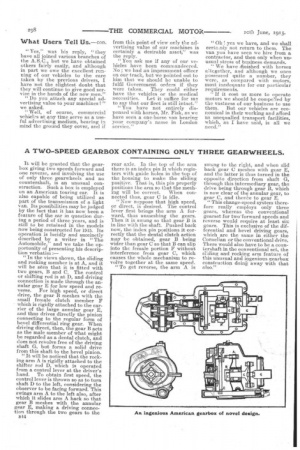

A TWO-SPEED GEARBOX CONTAINING ONLY THREE GEARWHEELS.

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

It will be granted that the gearbox giving two speeds forward and one reverse, and involving the use of only three gearwheels and no countershaft, is an unusual construction. Such a box is employed on an American touring car. It is also capable of being utilized as part of the transmission of a light van. Its possibilities may be judged by the fact that it has now been a feature of the ear in question during a period of three years, and is still to be retained in the models now being constructed for 1915. Its operation is lucidly and succinctly described by a writer in "The Automobile," and we take the opportunity of presenting his description verbatim :— " In the views shown, the sliding and rocking member is at A, and it will be seen that it is fitted with two gears, B and C. The control or shifting rod is at D, and driving connection is made through the annular gear E for low speed and reverse. For high speed, or direct drive, the gear B meshes with the small female clutch member F which is rigidly attached to the carrier of the large annular gear E, and thus drives directly the pinion connecting to the regular form of bevel differential ring gear. When driving direct, then, the gear B acts as the male member of what might be regarded as a dental clutch, and does not revolve free of the driving shaft G, but forms a solid drive from this shaft to the bevel pinion. "It will be noticed that the rocking arm A is rigidly attached to the shifter rod D, which is operated from a control lever at the driver's hand. To obtain first speed, the control lever is thrown so as to turn shaft D to the left, considering the observer to be facing forward. This swings arm A to the left also, after which it slides arm A back so that gear B meshes with the annular gear E, making a driving connection through the two gears to the B14 rear axle. In the top of the arm there is an index pin li which registers with guide holes in the top of the housing to make the sliding positive. That is, this pin properly positions the arm so that the meshing will be correct. When connected thus, gear C is idle. "Now suppose that high speed, or direct, is desired. The control lever first brings the arm A forward, thus unmeshing the gears. Then it is swung so that gear B is in line with the shaft. Pushed back now, the index pin positions it correctly that the dental clutch action may be obtained, gear B being wider than gear C so that B can slip into the female portion F without interference from gear C, which causes the whole mechanism to revolve together at the same speed. "To get reverse, the arm A is swung to the right, and when slid back gear C meshes with gear E, and the latter is thus turned in the opposite direction from shaft G, through this intermediary gear, the drive being through gear B, which is now clear of the annular gear, to gear C, and there to gear E.

"This change-speed system therefore really employs only three ...Tars) whereas the conventional gearset for two`forward speeds and reverse would require at least six gears. This is exclusive of the differential and bevel driving gears, which are the same in either the Cornelian or the conventional drive. There would also have to be a countershaft in the conventional set, the sEelin.g and rocking arm feature of this unusual and ingenious gearbox construction doing away with that also."