ek vehicle for all seasons

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

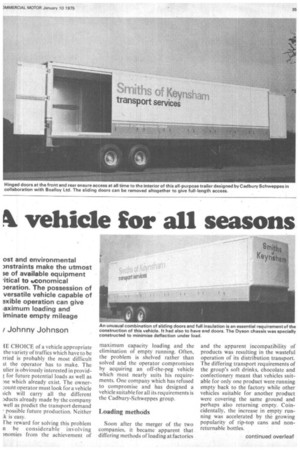

ost and environmental anstraints make the utmost se of available equipment *tic& to trconomical aeration. The possession of versatile vehicle capable of exible operation can give laximum loading and iminate empty mileage

Johnny Johnson

IE CI-1010E of a vehicle appropriate the variety of traffics which have to be rried is probably the most difficult it the operator has to make. The ulier is obviously interested in provid; for future potential loads as well as 3se which already exist. The ownercount operator must look for a vehicle iich will carry all the different Dducts already made by the company well as predict the transport demand possible future production. Neither is easy.

The reward for solving this problem n be considerable involving momies from the achievement of maximum capacity loading and the elimination of empty running. Often, the problem is shelved rather than solved and the operator compromises by acquiring an off-the-peg vehicle which most nearly suits his requirements. One company which has refused to compromise and has designed a vehicle suitable for all its requirements is the Cadbury-Schweppes group.

Loading methods

Soon after the merger of the two companies, it became apparent that differing methods of loading at factories and the apparent incompatibility of products was resulting in the wasteful operation of its distribution transport. The differing transport requirements of the group's soft drinks, chocolate and confectionery meant that vehicles suitable for only one product were running empty back to the factory while other vehicles suitable for another product were covering the same ground and perhaps also returning empty. Coincidentally, the increase in empty running was accelerated by the growing popularity of rip-top cans and nonreturnable bottles. Soft drinks are loaded over the side !aid the other products are end-loaded, vhile the pallet sizes used vary. Thus, he requirement was for a vehicle which :ould he loaded from the side and from he end, and it had to be capable of Lccommodating pallets of different izes. Moreover, for chocolate and conectionery, insulation was required.

To satisfy these demands, the :ompany has collaborated with Boalloy -td to produce a very versatile trailer.

The vehicle is based on the Linkliner :oncept. The body is built on a Dyson :hassis specially constructed to accept he sliding door design with side-raves milt straight and parallel to very fine olerances, the whole job extremely igid on the vertical plane to give ninimum deflection under load.

Internally, the vehicle has a 11.46m 37ft 3m) long unsupported roof with a teight of 2.18 m (7ft lin) and a width of 1.4m (7ft 101A in). The sides are 22 mm 0.819 in) thick double aluminium skin with balsa between. The roof is a '03mm (4in) thick polystyrene sandvich of prepainted dimple aluminium ind the front bulkhead is a polystyrene iluminium sandwich of similar thickless.

As there are no intermediate roof upports, the side aperture is an unnterrupted 11.39 m (37ft).

On each side, there is a 1.31 m (4ft tin) hinged door at the front, opening hrough 180 deg and secured forward by i stainless steel cable. This is followed ty seven sliding doors each 1.29m (4ft ',1,6 in) wide. Behind these is a rear tinged door 0.97m (3ft 2 in) wide which 'olds flat across the rear of the trailer.

Sharing a specially designed common tinge with the hinged rear-side door, the SO container-type rear doors will fold lat against the side of the vehicle.

Enterchangeable doors

The largest pallet carried is 4ft so that • 3! first opening the hinged rear sideloor, loading through that aperture, !nd then manipulating the sliding doors • ne by one it is possible to obtain veather-protected loading throughout. Uternatively, it is possible to remove he sliding doors altogether without lifficulty thus using all the available ide-loading space at one time. Each loor is interchangeable and this acilitates replacement.

The trailer is equipped with Dunlop ■ tablair suspension and super-single yres. This combination gives a smooth ide and has eliminated the need for load restraining equipment except at the end of the load. Shoring bars are provided at the last 4ft of the vehicle for this purpose.

The elimination of load restraints is useful, for the soft drinks traffic requires the full width while the chocolate requires only 7ft of width.

The top-suspended sliding doors are load bearing and soft drinks can be loaded from one side of the vehicle and positioned abutting the opposite side. Unloading can be accomplished from the side on which the traffic was loaded so that there is no difficulty with opening the sliding doors because the load prevents movement.

In any case, the hinged doors give access at all times so that it is possible to open any one of four to remove part of the load to release a sliding door which might be obstructed.

The floor, which is a sealed aluminium unit, will take fork-lift trucks. Because the loading hay at the particular factory at which fork-lifts are used is inclined, the rear 4ft of the floor has been reinforced with extra cros bearers to minimize the initial impac In addition, extra rigidity is obtainc from the widely positioned main bean made possible by the use of super-sing tyres.

Load security is obtained by a unusual method of locking. With a doors shut and secured and padlocks c the rear doors, the air is extracted fro! the vehicle by means of a built-in con pressor and the interior becomes vacuum, impregnable without tl appropriate equipment.

Since the prototype was introduced ! 1973, a number of these trailers ha' been placed in service with the group wholly owned subsidiary, J. B. Smithl Keynsham Ltd, and another is on trial the St Albans depot of the Schweppl group.

Although the initial cost is relative high, the company's bulk movemen are increasing and it is hoped to opera the vehicles up to 16 hours a day, at ti same time reducing empty running ar achieving capacity loading.