Tyres (3): rims and beads

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

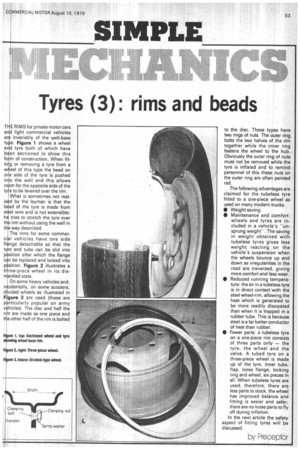

THE RIMS for private motor cars and light commercial vehicles ar invariably of the well-base ty e. Figure 1 shows a wheel a d tyre both of which have b en sectioned to show this fo m of construction. When fitti g or removing a tyre from a w eel of this type the bead on o e side of the tyre is pushed in o the well and this allows ro m for the opposite side of the ty e to be levered over the rim.

What is sometimes not realis d by the layman is that the b ad of the tyre is made from st el wire and is not extensible; h tries to stretch the tyre over th rim without using the well in th way described.

The rims for some commerci I vehicles have one side tinge detachable so that the ty e and tube can be slid into position after which the flange c n be replaced and locked into position. Figure 2 illustrates a t ree-piece wheel in its disantled state.

On some heavy vehicles and, i cidentally, on some scooters, d vided wheels as illustrated in F gure 3 are used (these are p rticularly popular on army v hides). The disc and half the ri are made as one piece and t e other half of the rim is bolted to the disc, These types have two rings of nuts. The outer ring bolts the two halves of the rim together while the inner ring fastens the wheel to the hub. Obviously the outer ring of nuts must not be removed while the tyre is inflated and to remind personnel of this these nuts on the outer ring are often painted red.

The following advantages are claimed for the tubeless tyre fitted to a one-piece wheel as used on many modern trucks.

• Weight saving.

• Maintenance and comfort: wheels and tyres are included in a vehicle's "'unsprung weight". The saving in weight obtained with tubeless tyres gives less weight reacting on the vehicle's suspension when the wheels bounce up and down as irregularities in the road are traversed, giving more comfort and less wear.

• Reduced running temperature: the air in a tubeless tyre is in direct contact with the steel wheel-rim, allowing the heat which is generated to be more readily dissipated than when it is trapped in a rubber tube. This is because steel is a far better conductor of heat than rubber.

• Fewer parts: a tubeless tyre on a one-piece rim consists of three parts only — the tyre, the wheel and the valve. A tubed tyre on a three-piece wheel is made up of the tyre, inner tube, flap, loose flange, locking ring and wheel, six pieces in all. When tubeless tyres are used, therefore, there are less parts to stock, the wheel has improved balance and fitting is easier and safer; there are no loose parts to fly off during inflation.

In the next article the safety, aspect of fitting tyres will be discussed.

by Preceptor