To Enhance Vacuum-brake Reliability

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

JUST as the problem of making. a joint in a vacuum system is relatively small, because the parts—unlike those of a pressure system—are automatically forced together, so the difficulty of preventing the entry of foreign matter from outside the, system is relatively great. The latter sometimes presents itself to designers of vacuum-brake apparatus.

It may arise in vacuum-hydraulic layouts when there is close juxtaposition of the two brake-actuating mediums, or in any vacuum system when certain parts are exposed to water. There have been cases of brake failure through freezing of water that has entered some vital part, and through a greater volume (probably) of water being drawn it under conditions of total submersion.

Admittedly, it is unusual to apply brakes when a machine is crossing a ford, but, particularly in the case of vehicles used by the armed Forces troubles have been experienced in this way.

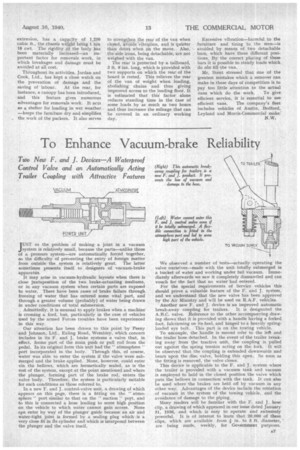

Our attention has been drawn to this point by Feeny and Johnson, Ltd., Ealing Road, Wembley, which concern includes in its F. and J. brake systems a valve that, in effect, forms part of the main push or pull rod from the pedal. In its original form this unit had the " atmosphere " port incorporated in the body. Through this, of course, water was able to enter the system if the valve were submerged and the brake applied. None, however, could enter via the bellows, which are hermetically sealed, as is the rest of the system, except at the point mentioned and where the plunger, forming part of the brake rod, enters the valve body. Therefore, the system is particularly suitable for such conditions as those referred to.

In a new F. and J. control-valve unit, a drawing of which appears on this page, there is a fitting on the " atmosphere" port similar to that on the " suction" port, and to this is connected a hose leading to some high position on the vehicle to which water cannot gain access. None elen enter by way of the plunger guide because an air and water-tight joint is formed by a sealing plug which is a very close fit in As cylinder and which is interposed between the plunger and the valve itself.

We observed a number of tests—actually operating the valve ourselves—made with the unit totally submerged in a bucket of water and working under full vacuum. Immediately afterwards we saw it completely dismantled and can vouch for the fact that no water had entered.

For the special requirements of Service vehicles this should prove a valuable feature of the F. and J. system, and we understand that the new valve has been approved by the Air Ministry and will be used on R.A.F. vehicles.

Another new F. and J. device is an improved automatic break-away coupling for trailers. It is designated the A.B.C. valve. Reference to the other accompanying drawing shows that it is provided with a handle having a forked foot, fulcruming on its heel, and hinged to a heavily springloaded eye bolt. This part is on the towing vehicle.

To uncouple, the handle is moved over to .the left and the trailer hose detached. In the event of the trailer breaking away from the tractive unit, the coupling is pulled out against the spring tension acting on the fork. It will be observed that the coupling is extended downwards and bears upon the disc valve, holding this open. So soon as the fitting is removed, the valve closes.

This device is applicable to the F. and J. system where the trailer is provided with a vacuum tank and vacuum is employed to hold in the closed position the valve which puts the bellows in connection with the tank. It can also be used where the brakes are held off by vacuum in any other way. Advantages of the device include the retention of vacuurri in the system of the towing vehicle, and the avoidance of damage to the piping.

Many readers will he familiar with the F. and J. hose clip, a drawing of which appeared in our issue dated January 31, 1936, and which is easy to operate and extremely powerful. It is of interest to learn that 20,000 of these clips, which are available from in. to 9 ft. diameter, are being made, weekly, for Government purposes.