Jake meets ADR Tipper trucks under scrutiny

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

• Following SMMT-monitored trials at the Ministry of Defence's Hum n test establishment Jacobs Europe has confirmed that its compression engine brakes meet the newly imposed ADR regs.

Tests were carried out using a Cummins L10-350 Celect Euro-1 engined Foden tractor with Jake 404D engine brake and a loaded trailer at just over 40,000kg GCW.

Simulating downhill stabilisation speed of 30km/h with a towing test over 6km, Jacobs recorded drawbar pull, vehicle speed, engine rpm and engine boost pressure.

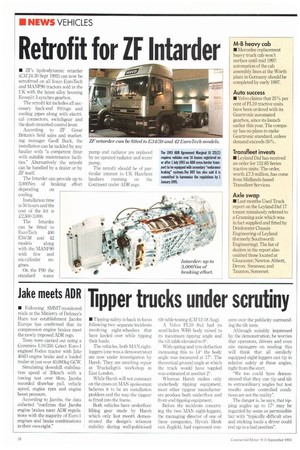

According to Jacobs, the data collected "confirms that Jacobs engine brakes meet ADR regulations with the majority of Euro-1 engines and brake combinations in their own right." • Tipping safety is back in locus following two separate incidents involving eight-wheelers that have keeled over while tipping their loads.

The vehicles, both MAN eightleggers (one was a demonstrator) are now under investigation by Harsh. They are awaiting repair at Truckalign's workshop in East London.

While Harsh will not comment on the cases an MAN spokesman believes it to be an installation problem and the way the tipgear is fitted into the frame.

Both vehicles have underfloor lifting gear made by Harsh which only last month demonstrated the design's inherent stability during well-publicised

ill table testing (M l2-)Aug).

A Volvo FL10 8x4 had its sand-laden WBS body raised to its maximum tipping angle and the tilt table elevated to 90.

With spring and tyre deflection increasing this to 14° the body angle was measured at 17°. The theoretical ground angle at which the truck would have toppled was estimated at another 2°.

Whereas Harsh makes only underbody tipping equipment, most other tipgear manufacturers produce both underfloor and front-end tipping equipment.

Before the incidents concerning the two MAN eight-leggers, the managing director of one of these companies, Hyva's Henk van Zegfeld, had expressed con cern over the publicity surrounding the tilt tests.

Although suitably impressed by the demonstration, he worries that operators, drivers and even site managers on reading this will think that all similarly equipped eight-leggers can tip in relative safety at these angles, right from the start.

"We too could have demonstrated that they can tip and tilt to extraordinary angles but test results under controlled conditions are not the reality".

The danger is, he says, that tipping angles up to 17° may be regarded by some as permissible but with "typically difficult sites and sticking loads a driver could end up in a bad position".