A BIG

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

PULL at LOW FUE I:10 ST POWER with economy were the main features observed during the road test of the Atkinson six-wheeled goods chassis. Although the tests were made over a 100-mile course I found no points to criticize in its performance or design.

An inspection of the construction of the Atkinson chassis reveals it to be of straightforward design, and to have stamina in its background. It has a generously proportioned frame, adequately braced by channel section cross members bolted in position, and is powered by the well-tried Gardner 6LW oil engine. The David Brown gearbox employed in the chassis is one of thelatest models—which eases the task of driving.

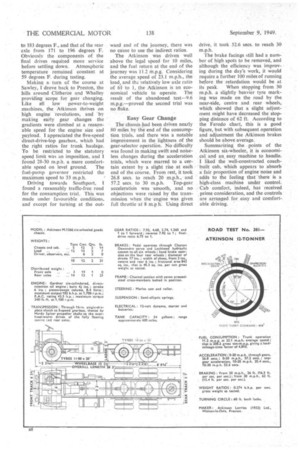

High Engine Mounting The engine is positioned high in the frame and is supported by a single mounting at the front and by brackets, between the clutch housing and frame, at the rear. There is a thin absorbent packing piece between the brackets and the frame. Engine, clutch and gearbox ere formed as a unit, with The clutch assembly fully enclosed to prevent entry of dust or

water, To simplify gear . changing the three upper ratios are constant-mesh and the long change-speed !ever has a relatively short but positive move ment, .

The propeller shaft between the gearbox 'arid axles is a Hardy Spicer two-piece ,unit, with the centre bearing suspended from a crossmember.... Both centre and rear axles have overhead worm drives, which are housed in axle casings of massive 66

proportions. There is a balance-beam linkage between the springs of these axles; and an ingenious lubrication system is incorporated to ensure thorough lubrication to the bogie and shackle pins.

In this arrangement, a plunger pump is fitted to each bearing cap, and its piston is reciprocated by an eccentric pin on the balance-beam spindle. Lubricating oil is supplied to the pump from a reservoir, which is mounted on the balance-beam bracket. The lubricant is forced past • a non-return valve. It travels first to the balance-beam bush, then to the shackle-pin bushes, and finally returns to the reservoir. Trunnionpattern spring shackles are used at the centre and rear-axle springs to assist axle articulation.

A further interesting detail of the Atkinson design is the fabricated spring-hanger brackets, which afford strength with lightness. These brackets are of all-welded fabrication, suitably shaped to obtain maximum support from the frame, and bolted to the bottom and side of each frame member.

The Lockheed hydraulic operatin cylinders of the rear braking system are each attached through a swivel pin to an outrigger .formed in the

axle casing. The opposite ends of the cylinders are attached directly to the brake-cam levers. There is a simple method of adjustment for wear by increasing the length of the operating. unit.

Because of the brake servo position, difficulty was experienced in distributing the two-ton iron weights evenly along the length of the bare chassis. The weighbridge figures showed that the proportion of the gross load on the front axle was reasonable, there being 21.3 per cent. carried by the front axle, and the remainder 'by the centre and rear axles. The -rear suspension ensured that the load was equalized between the centre aridrear axles.

After leaving the. Preston weigh-. bridge, I drove towards Clitheroe and Skipton, to , look for suitable ground for a hill climb. After 10 miles, the Atkinson was sufficiently warm for a consumption trial, and a brief halt was made to connect the test tank intt the fuel supply line.

Traffic conditions were bad during this trial, and a one-way traffic system through.Mellor Brook caused a short halt and gave a poor start to the climb out of the village. Congestion in Whalley was responsible for further .delay, and the test was abandoned at the far side of the town. As a matter of interest, measured the quantity 'of fuel used, and found that the seven Miles had been covered with a consumption. equivalent to 9.6 m.p.g., The journey was continued to the Spteed." Eagle 'Hotel, which .• is the starting. point of the old hilt at SaWley, Water. and Oil temperatures

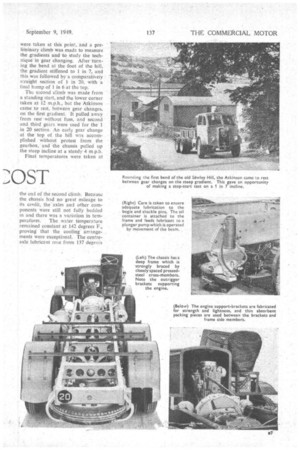

were taken at this point, and a preliminary climb was made to measure the gradients and to study the technique in gear changing. After turning the bend at the foot of the hill, the gradient stiffened to l in 7, and this was followed by a comparatively • straight section of I in 20, with a final hump of I in 6 at the top.

Tht; second climb was made from a standing start, and the lower corner taken at 12 m.p.h., but the Atkinson came to rest, between gear changes, on the first gradient. It pulled away from rest •without fuss, and second and third gears were used for the I in 20 section. An early gear change at the top of the hill was accomplished without protest from the gearbox, and the chassis pulled up the steep incline at a steady 4 m p.h.

Final temperatures were taken at the end of the second climb. Because the chassis had no great mileage to its credit, the axles and other components were still not fully bedded in and there was a variation in tem peratures. The water temperature remained constant at 142 degrees F., proving that the cooling arrangements were exceptional. The centreaxle lubricant rose from 137 degrccs to 183 degrees F., and that of the rear axle from 171 to 196 degrees F.Obviously the components of the final drives required more service before settling down. Atmospheric temperature remained constant at 59 degrees F. during testing.

Making a turn of the course at Sawley, I drove back to Preston, the hills around Clitherete and .Whalley providing scope for gear changing.

Like all . low power-to-weight machines, the Atkinson thrives on high engine revolutions, and 'by making early gear changes the gradients were climbed at a reasonable speed for the engine size and payload. I appreciated the five-speed. direct-drive-top gearbox, which had the right ratios for trunk haulage. To be restricted to the statutory speed limit was an imposition, and I found 28-30 m.p.h. a more comfort

able speed on level ground. The fuel-pump governor restricted the maximum speed to 33 m.p.h.

Driving towards Southport, found a reasonably traffic-free road for the consumption trial. This was made under favourable conditions, and except for turning at the out

ward end of the journey, there was no cause to use the indirect ratios.

The Atkinson' was driven well above the legal speed • for 10 miles, and the fuel return at the end of the journey was 11.2 M.p.g. Considering the average speed of 23.1 m.p.h.., the load, and the relatively low axle ratio of 64 to 1, the Atkinson is an economical vehicle to operate. The result of the abandoned test-9.6 m.p.g.—proved the second trial was no fluke.

Easy Gear Change

• The chassis had been driven nearly 80 -miles. by the end of the consumption trials, and there was a notable improvement in the lightness of the gear-selector operation. No difficulty was found in making swift and noiseless changes during the acceleration trials, which were marred to a certain extent by a slight rise at each end of the course. From rest, it took 26.8 secs. to reach 20 m.p.h.,and 57.2 secs. to 30 m.p.h. •Top-gear acceleratisin was -smooth, and no objections were raised by the transmission when the • engine was given full throttle at. gtn.p h Using direct

drive, it took 52.6 secs. to reach 30 m.p.h.

The brake facings still had a number of high spots to be removed, and although the efficiency was improving during the day's work, it would require a further 100 miles of running before the retardation would be at its peak. When stopping from 30 m.p.h. a slightly heavier tyre marking was made on the road by the near-side, centre and rear wheels, which showed that a slight adjustment might have decreased the stopping distance of 62 ft. According to the Ferodo chart, this is a good figure, but with subsequent operation and adjustment the Atkinson brakes should be above average.

Summarizing the points of the Atkinson six-wheeler, it is economi.caI. and an easy machine to handle. I liked the well-constructed coachbuilt cab, which appears to absorb a fair proportion of engine noise and adds to the feeling that there is a high-class machine under control.

• Cab comfort, indeed, has received prime consideration, and the controls are arranged for easy and comfortable driving.