THE MECHANICAL EQ ■ IT OF A REPAIR SHOP.

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

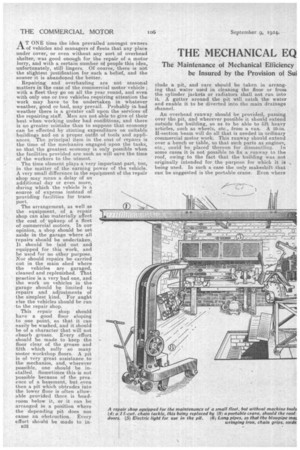

The Maintenance of Mechanical Efficiency be Insured by the Provision of Sui s of a Fleet of Commercial Motors can only r Equipment as is Herein Described.

AT ONE time the idea prevailed amongst owners of vehicles and managers of fleets that any place under cover, or even without. any sort of overhead shelter, was good enough for the repair of a motor lorry, and with a certain number of people this idea, unfortunately, still lingers. Of course, there is not the slightest justification for such a belief, and the sooner it is abandoned the better.

Repairing and overhauling are not seasonal matters in the case of the commercial motor vehicle ; with a fleet they go on all the year round, and even with only one or two vehicles requiring attention the work may have to be undertaken in whatever weather, good or bad, may prevail. Probably in bad weather there is a greater call upon the services of the repairing staff. Men are not able to give of their best when working under bad conditions, and there is no greater mistake than to suppose that economy can be effected by stinting expenditure on suitable buildings and on a proper outfit of tools and appliances. The principal item in the cost of repairs is the time of the mechanics engaged upon the tasks, so that the greatest economy is only possible when the facilities provided are such as will save the time of the workers to the utmost.

The arrangement, as well ae the equipment, of a repair shop can also materially affect the cost of upkeep of a fleet of -commercial motors. In our opinion, a shop should be set aside in the garage where all repairs should be undertaken. It should be laid out and equipped for this work, and be used for no other purposeNor should repairs be carried out in the main shed where the vehielee are garaged, cleaned and replenished. That practice is a very bad one, and the work on vehicles in the garage should be limited to repairs and adjustments of the simplest kind. ?or aught else the vehicles should be run to the repair shop.

This repair shop should have a good floor sloping to one point, so that it can easily be washed, and it should be oi a character that will not absorb grease. Every effort should be made to keep the floor clear of the grease and filth which sully so inany motor workshop floors. A pit is of very great assistance to the mechanies, and, wherever possible, .one should be installed. Sometimes this is not possible because of the presence of a basement, but even then a pit which obtrudes into the lower floor is often allowable provided there is headroom below it, or it can be arranged in a position where the depending pit. does not cause an obs.4truction. Every tffort should be made to in

1332 elude a pit, and care should be taken in arranging that water used in cleaning the floor or from the cylinder jackets or radiators shall not run into it. A gutter around the pit will catch the water and enable it to be diverted into the main drainage channel.

An overhead runway should be provided, passing over the pit, and wherever possible it should extend outside the building, so as to be able to lift heavy articles, such as wheels, etc., from a van. A 10-in. H-section beam will do all that is needed in ordinary commercial motor work. This runway should extend over a bench or table, so that such parts as engines, etc., could he placed thereon for dismantling. In some cases it is not possible to fix a runway to the roof, owing to the fact that the building was not originally intended for the purpose for which it is being used. In such a case the only makeshift that can be suggested is the portable crane. Even where a runway is installed, however, the portable crane is often very useful.

A four-wheeled trolley, of strong make, with T handle, is an essential part of an outfit, and can be used for carrying about such parts as are too heavy to handle. ft is often useful for moving a chassis which has had one of its axles removed, and has even been used to bring home a chassis after an accident.

A low-built Samson is essential for lowering engines, gearboxes, etc., on to when they are being removed. A pair of 15-cwt. chain blocks will be found the most useful size of tackle for such purposes as garage work.

Two jacks should be provided of a type suitable for placing under axles, while two higher ones suitable for lifting frames will be found to economize time. Some strong blocks of wood will be required for blocking up chassis which have to be left standing when an axle has been removed.

A firm bench, with a vice not less than 5 ins. wide and of the parallel-jaw type, preferably steel and not cast-iron, are essential for the heavier parts of the work. A good plan is to have a smaller bench with about a 3-in.-jaw vice for lighter work. This bench should be separate from the heavier bench, and should be kept essentially for such work as the electric outfit, carbqretter, etc. In fixing vices it is essential that they should be in such a position tb t long articles can be held upright.

Gas should be laid on to a stove suitable for heating soldering irons and sweating parts together. The larger soldering iron should not weigh less than 2 lb. A smaller one will be useful for such parts as electric fittings. A portable forge, combined with a blowpipe and provided with long armoured flexible hose, so that it can, if needed, be moved to heat any part that is not portable, will be found an advantage. In installing such a forge, it is a mistake to have one of too small a size, as it will so often prove to be useless where some large article requires heating. An anvil and a heavy sledge-hammer should form part of the outfit.

A large wringing iron, as shown in our illustration, is essential—one end for straightening and the other for twisting bent parts. An old leg vice forms a very efficient wringing iron, as when a bent part is heated and held in a fixed vice, the leg vice can be used as a wringing iron, as the part to be straightened can be firmly gripped in its jaws.

When any part which requires heating at one exact i

spot s placed in a forge, it will be found difficult to con fine the heat to the particular spot to be straightened. The best method of doing this is to heat the article as near to the required spot as possible, and to cool the part which is not required to be hot by pouring water on it until only the bent part is hot. This can best be done by using an ordinary kettle, as the water can be directed to the exact spot required better than from a ladle ; so any oid kettle of large size will be found a useful addition. Care must, however, be taken that any part so cooled should be annealed afterwards, as otherwise the steel may be left in a brittle condition. For cleaning off parts, a bath of paraffin should be provided. If an open yard is available, a great deal of time and money can be saved by merely swilling the parts in the paraffin bath. and rubbing them with a brush, then laying them on the ground and playing on them with water from a. hose, as used for cleaning the vehicles. This will be found to drive off all dirt and to leave the parts perfectly clean without the cost of rags for wiping.

In cases where more serious repairs to fleets are to be carried out, it is necessary to have a more extensive outfit, including a lathe, drilling machines, shaper, etc. In our issue of July 15th last, we fully described the class of lathe and its equipment which will be found most useful in the repair of commercial vehicles.

If a lathe is installed, it is practically useless unless it is of sufficient size to tackle the work necessary for eommercial-niotors,,and the mistake is often made of providing too. small a lathe, which would only be useful for small pleasure-car work. A full set of chucks; three-jaw, four-ja.w and drill-chuck should be provided.

For general repairs, a shaper will be found more useful than a raffling machine, as the latter is really of little use unless a large variety of milling cutters. and a machine for sharpening them are provided. ' If a drilling machine is installed, one of the radial type will be found the best for larger work, whilst a sensitive type is most suitable for the smaller holes. An ample supply of small tools will expedite the work and save men's time, although one seldom finds a

repair shop which has half the equipment it should have, much time and money being wasted in consequence. Cleanliness and order are essential if work is to be done properly and at the right cost, and it unquestionably pays to provide for proper supervision, so as to ensure the maintenanee of a high standard of workshop method_ All useless scrap should be cleared out, as its accumulation only hinders work. Small tools are best kept in cupboards with expanded metal doors, so that the contents can be seen at a glance. Wall plugs for lighting should be fitted to all the walls, and one in the pit will be found useful. The accompanying view is not intended as a typical lay out, as, in this matter, so many things have to be into nto consideration ; it is intended, however, to show the appliances which, if installed, will be found to save both time and money.