The Purchase Department.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Where to Buy your Supplies.

You Can Get It At " A.B.C." (Motherwell).—You will be able to obtain the gearbox from Benjamin Whitaker, 7, Victoria Street, London, S.W.

The Barron Patent expanding Ferrules.

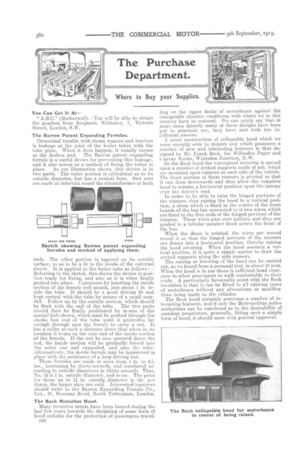

Occasional trouble with steam wagons and tractors is leakage at the joint of the boiler tubes with the tube plate. When it does happen, it usually occurs at the firebox end. The Barron patent expanding ferrule is a useful device for preventing this leakage, and it also serves as a method of fixing the tubes in place. As our illustration shows, this device is in two parts. The outer portion is cylindrical as to its outside diameter, but has a conical bore. Saw cuts are made at intervals round the circumference at both ends. The other portion is tapered on its outside surface, so as to be a fit to the inside of the external sleeve. It is applied to the boiler tube as follows :— Referring to the sketch, this shows the device in position ready for fixing, and also as it is when finally pushed into place. Commence by inserting the inside section of the ferrule bell mouth, just about 1 in. inside the tube. It should be a good driving fit and kept central with the tube by means of a small mandril. Follow up by the outside section, which should be flush with the end of the tube. The two parts should then be finally positioned by means of the special bolt shown which must be pushed through the smoke box end of the tube until it protrudes far enough through past the ferrule to carry a nut. It has a collar at such a distance down that when in its position it bears on the rear end of the inside section of the ferrule. If the nut be now screwed down the rod, the inside section will be gradually forced into the outer one and expanded, and also the tube. Alternatively, the inside ferrule may be hammered in place with the assistance of a long driving bar.

These ferrules are made in sizes from 1 in. to 2(4' ins. increasing by thirty-seconds, and numbered according to outside diameters in thirty-seconds. Thus, No. 32 is 1 in. outside diameter, and so on. The price for those up to 1 in. outsidg diameter is 12s. per dozen, the larger sizes pro rata. 'Interested inquirers should write to the Barron Expanding Ferrule Co., Ltd., 27, Braemar Road, South Tottenham, London.

The Beck Motorbus Hood.

Many inventive minds have been turned during the last few years towards the designing of some form of hood suitable for the protection of passengers travel n56 ling on the upper decks of motorbuses against the changeable climatic conditions with which we in this country have to contend. We can safely say that in most cases directly many of these designs have been put to practical use, they have met with but indifferent success.

A novel construction of collapsible hood which we were recently able to inspect and which possesses a number of new and interesting features is that designed by Mr. Frank Beck, the Willesden Paper and Canvas Works, Wiilesden Junction, N.W. In the Beck hood the waterproof covering is spread upon a number of arched supports made of ash, which are mounted upon runners on each side of the vehicle. The front portion of these runners is pivoted so that it can drop downwards and thus allow the complete hood to assume a horizontal position upon the canopy over the driver's seat.

In order to be able to raise the hinged portions of the runners, thus raising the hood to .a vertical position a drum which is fixed in the centre of the front boards of the bus has connected to it two wires, which are fixed to the free ends of the hinged portions of the runners. These wires pass over pulleys, and they are guided in a tubular member fixed acros the front of the bus.

When the drum is rotated, the wires are wound round it so that the hinged portions of the runners are drawn into a horizontal position. thereby raising the hood covering. When the hood assumes a vertical position, it is quite a simple matter to draw the arched supports along the side runners. The raising or lowering of the hood can be carried out, as we found from a personal test, in about 30 secs. When the hood is in use there is sufficient head clearance to allow passengers to walk comfortably to their seats. A particularly favourable point with the Beek invention is that it can be fitted to all existing types of motorbuses without any alterations or modifications being made to the vehicles. The Beck hood certainly possesses a number of interesting features, and if only the Metropolitan police authorities can he convinced as to the desirability of omnibus proprietors, generally, fitting such a simple form of hood, it should meet with general approval.