ELECTRIC TRUC1 IN DOCK SHEDS.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

A Review of the Many-sided Activiti at the West Toxteth Dock Berths

leet of Electric Trucks and Tractors minent Steamship-owning Concern.

TO cheapen the processes of handling cargo on the quays, Elder, Dempster and Co., Ltd., the well-. known steamship-owning concern, has during the past few years sunk considerable capital in the provision of up-to-date plant at its berths, West Toxteth Dock, Liverpool. This is the portion of the Mersey Dock Estate where inward cargoes from West Africa are concentrated. The cargoes amount to over 200,000 tons Per annum, of which 35,000 tons consist of logs of timber, and the remainder principally casks of palm oil and bagged produce.

Nowhere along the line of Liverpool's .doeks is the suitability of the electric truck for the clearance of cargoes from the ship's side more forcibly. demonstrated. There could be few more 'animated traffic

scenes than are provided by• this lively little fleet . of 22 machines running in and out of the dock shed's, ' transporting such miscellaneous loads as hides, fibre,• palm kernels and other Oil-bearing seeds -and timber, cocoa, palm oil, etc., all of which • are stowed in the sheds or on the quays. pendingits removal by barge, motor lorry or horsed wagon to local factories, warehouses, etc.

The fleet consists of . 15 Greenbat 2'ton trucks, which are used for var!ou s classes o f traffic, two Lansing Model H 2-ton platf r m trucks, a B.E.V. 10 c w t . truck, which tackles general shed work, three Lansing Model O 5-ton tractors and a Walker 10-ton tractor, all the tractors • being employed for dealing with trailer loads.

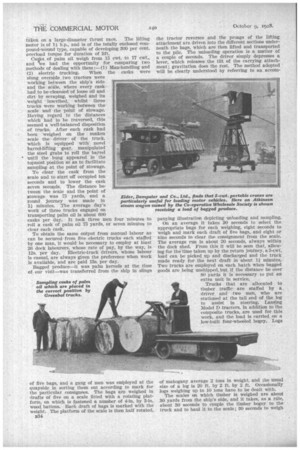

The other cargohandling plant which is in • service comprises 'an elec n32 tric w'Amowing machine for recovering an,c1 cleaning goods spilt from bags, two 7-ton Goliath electric cranes, 30 5-cwt. portable electric cranes and one each of 1-ton and 7-ton capacity, two 5-ton and one 1-ton steam cranes, five 10-ton sunken timber scales, ten 3-ton sunken oil scales, 22 portable bag-weighing scales and a number of beam Scales for weighing tin ore and for checking The weights recorded by the automatic bag scales. For working the portable cranes there are 85 electric connecting boxes for the 5-cwt. cranes and 15 for the 7-ton cranes. It is necessary to give details of the composition of this plant for the purpose of clarity in following our explanation of the working Of the electric trucks.

Every item of cargo, as it is discharged 'tom the ship, has to be weighed and marked, and unless these operations can be performed quickly there is a loss of efficiency, which cumulatively would be serious. Many of the cargo-carrying vessels of Elder, Dempster and Co., Ltd., are motor ships, the cargo of which is discharged from four hatches, sometimes five. On the day of our visit to West Toxteth Dock, palm kernels in bags were being discharged from two holds, casks of palm oil from the third and timber from the fourth, and all this produce was taken from the ship's.side by powerful little Greenbat 2-ton composite trucks. The Greenbat standard unit is equipped with patent elec trically operated cask-handling gear and a patent detachable appliance for handling bags, bales and cases. The cask gear is fitted at the Control end of the vehicle, leaving, the platform space clear, whilst the towing

gear is fitted at the platform end so as to avoid damage to the special attachments in ease the load being towed overruns the truck. The purpose" in providing the special gear is primarily to eliminate the time lost in loading and unloading the truck by hand labour. The•catsk-lifting gear is built up with a steel-channel jib and with cast-iron steel grabs having pivoted endsand cast-steel shoe pieces. The grab arms are operated by cranks and link connections and the steel draw shaft by means of a hard brass nut carried on ball bearings, the thrust being

taken on a large-diameter thrust race. The lifting motor is of 11 h.p,, and is of the totally enclosed compound-wound type, capable of developing 300 per cent. overload torque for duration of lift.

Calks of palm oil weigh from 15 cwt. to 17 cwt., and 'we had the opportunity for comparing two methods of dealing with them:— (1) Man-handling and

(2) electric trucking. When the casks were 'slung overside two tractors were working between the ship's side and; the settle, where every cask,

had. to be'cleanSed of loose oil and dirt by scraping, weighed and its weight inscribed, whilst three trucks were working between the scale and the point of stowage. Having regard to the distances which had to be traversed, this seemed a well-balanced disposition of trucks. After each cask had been weighed on the sunken scale the driver • of the truck, which is equipped with novel barrel-lifting gear, manipulated the steel grabs to roll the barrel until the bung appeared in the topmost position so as to facilitate sampling at the point of stowage. To clear the cask from the scale and to start off occupied ten seconds and to lower the cask seven seconds. The distance between the scale and the point of stowage was 75 yards, and a round journey was made in 1/ minutes. The average day's work of three trucks engaged on transporting palm oil is about 600 casks per day. It took three men four minutes to roll a cask of palm oil 75 yards, or seven minutes to clear each cask.

To obtain the same output from manual labour as can be secured from five-electric trucks each staffed

by one man, it would be necessary to employ at least 26 dock labourers, whose rate of pay, by the way, is 12s. per day. Electric-truck drivers, whose labour is casual, are always given the preference when work is available, and are paid 13.s. per day.

Bagged produce—it was palm kernels at the time of our visit—was transferred from the ship in slings of five bags, and a gang of men was employed at the quayside in sorting them out according to mark for the particular consignees. The bags are weighed in drafts of five on a scale fitted with a rotating platform, on which is fastened a number of 4-in. by 3-in. wood, battens. Each draft of bags is marked with the weight. The platform of the scale is then half rotated, B34 the tractor reverses and the prongs of the lifting attachment are driven into the different sections underneath the bags, which are then lifted and transported to the pile. The unloading operation is a matter of a couple of seconds. The driver simply depresses a lever, which releases the tilt of the carrying attachment; gravitation does the rest. The method adopted will be clearly understood by referring to an accora panying illustration depicting unloading and sampling.

On an average it takes 30 seconds to select the appropriate bags for each weighing, eight seconds to weigh and mark each draft of five bags, and eight or nine seconds to clear the consignment from the scale. The average run is about 20 seconds, always within the dock shed. From this it will be seen that, allowing for the time taken up by the return journey, a 5-cwt. load can be picked up and discharged and the truck made ready for the next draft in about 1/ minutes. Two trucks are employed on each hatch when bagged goods are being unshipped, but if the distance be over 80 yards it is necessary to put an extra unit in service.

Trucks that are allocated to timber traffic are staffed by a driver and two men, who are stationed at the tail end of the log to assist in steering. Lansing Model D tractors, in addition to the composite trucks, are used for this work, and the load is carried on a low-built four-wheeled bogey. Logs of mahogany average 2 tons in weight, and the usual size of a log is 20 ft. by 2 ft by 2 ft. Occasionally logs weighing up to 10 tons have to be dealt with.

The scales on which timber is weighed are about 30 yards from the ship's side, and it takes, as a rule, about 30 seconds to couple the timber bogey to the truck and to haul it to the scale; 30 seconds to weigh

and mark the log and about 20 seconds to haul the log on to the quay, where it is lifted by a 7-ton Goliath crane and transported to the particular point where It is to be stored.

As every log is marked with the identification symbol of the importer, a system of careful classifica tion has to be followed, so as to save time when the consignees' vehicles arrive to load up and to take the logs to the local storage yards, or perhaps to a railway goods depot for forwarding to another destination. Goods may be left on the quays or in the sheds for a period of 72 hours without charge, but after that time a rental is charged oa a progressive scale.

As has been stated above, over 200,000 tons of inward cargoes pass through the West • Toxteth sheds of Elder, Dempster and Co., Ltd., every year. Some idea of the capacity of the fleet of electric trucks for dealing with heavy tonnages may be gathered from the statement that they can clear from the ship's side 450 tons of palm on, 230 tons of timber or from 130 to 150 tons of bagged produce, according to its nature, in the working day of eight hours per hatch, and stow it in sheds 50 yards wide or on the open quays on the opposite side of the shed. Fotb off-loading bagged produce the 5-cwt. cranes, staffed by a driver and two men who hook on the bags, which are lifted two at a time, can fully load a wagon with 140 bags in 20 minutes, the driver being stationed on the wagon for placing the bags in position. The two 7-ton Goliath cranes can off-load 1,000 tons of timber and palm-oil per day and, if necessary, this "figure can be doubled by the full use of the heavy portable cranes. Elder, Dempster and Co., Ltd., has an efficiently equipped charging station and repair shop in the northeast corner of the West Toxteth dock shed. Here the charging plant comprises three generators of 400 amperes at 75 volts capacity, and one of 100 amperes at 100 volts capacity. These have an output which enables the batteries of the 22 vehicles to be charged in six hours, starting at 11 p.m. When work is finished at 5 p.m. the batteries are allowed six hours in which to cool, as it is considered important that the temperature should not at any time exceed 115 degrees.

Three batteries are charged in parallel and, as there are two panels to each generator, six batteries can be simultaneously replenished from each. A Parsons 21 h.p. paraffin engine is installed as a standby unit to drive a generator in the event of a failure of the supply.

Once every year each electric vehicle is completely stripped. Three men constitute the maintenance department and they are able to take down a" machine, clean out the batteries, which are refilled with new electrolyte, and reassemble it within a week. The two most frequent causes of breakdowns are broken springs and broken axle shafts, which are brought about by overloads and driving over the heavily corrugated dock-shed floors and roads. The efficiency of the maintenance department is such that no matter what class, of breakdown occurs to a: truck it can be rectified within four hours. Some of the Nife batteries have been in serviee 4 years.

During the past 12 mOnths the power Consuniption of this busy little fleet. of truck § was .17,004) units and of, the cranes 23,000 units, the cost' , per unit being approximately The average life of the tyres on . the electric trucks is about four years, which must be considered satisfactory having regard to the rigorous conditions of operation. After a. cargo of palm oil has been cleared from the ship the surface of the dock shed is thick with sticky oil, and owing to the weight carried on the trucks this seems to be pressed into the rubber. There is a special attachment for one of the trucks which enables it to scrape up oil and dirt dff the floor. The speed of the electric trucks averages 8 m.p.h.