Using the cat trap

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

The diesel engine appears to be public enemy number one, but could catalytic converters and particulate traps change all that?

cience might tell us what is achievable, but it is economics which tells us what is desirable. So it is that we have the spectre of misconception, distrust and scepticism between engine manufacturers and those producing catalytic converters and other equipment that can push up costs.

In a presentation at Telford, Giles Hundleby from Ricardo said that particulate traps could carry a fuel consumption penalty of 10%. Not so, says Eminox, the UK's leading after-treatment equipment supplier. It says that by using Johnson Matthey's latest technology particulates, NOx, hydrocarbons and carbon monoxide can all be reduced with only a 2-3% fuel consumption penalty This assertion is based on Johnson Matthey's Continuously Regenerating Trap system, which uses an oxidation catalyst followed by a particulate filter. This is claimed to reduce particulates, carbon monoxide and hydrocarbons by over 90%: NOx comes down by a more moderate 5%. The system has little to do with mechanical science but everything to do with chemistry as Eminox's sales director, Michael Galey, explained.

First of all is the oxidation catalyst which, as its name suggests, adds oxygen to the gases passing through it. So carbon monoxide is changed to carbon dioxide (CO + 0 COO. CO2 is a "greenhouse" gas, but CO is more poisonous. Hydrocarbons become water plus carbon dioxide (HC + 0 –■ H20 + CO2).

Diesel smell

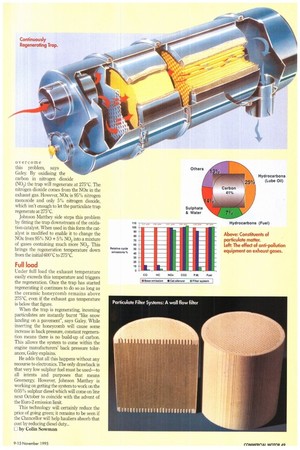

The diesel smell is reduced by the removal of the polyaromatic hydrocarbon fraction. As this can account for 32% of the mass of a particulate, the effect is to reduce the size of particulates although the number will remain unaltered.

With the latest technology the conversion becomes more efficient with temperatures as low as 250°C, says Galey, and this is easily reached downstream of the turbocharger. It can all be achieved using normal diesel and without any electronic control.

As to the longevity of a catalytic converter, Galey says that 700 have been in operation in Swedish buses for three years with no failures to date. On fuel consumption, he says that used on its own the catalyst will impose a penalty of about 1%.

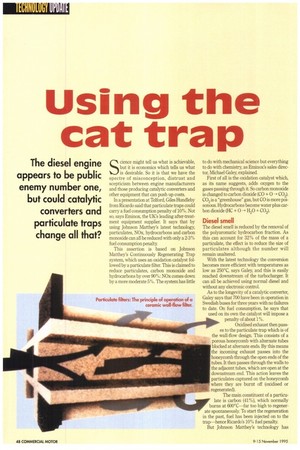

Oxidised exhaust then pass es to the particulate trap which is of the wall-flow design. This consists of a porous honeycomb with alternate tubes blocked at alternate ends. By this means the incoming exhaust passes into the honeycomb through the open ends of the tubes. It then passes through the walls to the adjacent tubes, which are open at the downstream end. This action leaves the particulates captured on the honeycomb where they are burnt off (oxidised or regenerated).

The main constituent of a particulate is carbon (41%), which normally burns at 600°C—far too high to regenerate spontaneously. To start the regeneration in the past, fuel has been injected on to the trap—hence Ricardo's 10% fuel penalty But Johnson Matthey's technology has overcome this problem, says Galey. By oxidising the carbon in nitrogen dioxide

(NO2) the trap will regenerate at 275°C. The nitrogen dioxide comes from the NOx in the exhaust gas. However, NOx is 95% nitrogen monoxide and only 5% nitrogen dioxide, which isn't enough to let the particulate trap regenerate at 275°C.

Johnson Matthey side steps this problem by fitting the trap downstream of the oxidation catalyst. When used in this form the cat

alyst is modified to enable it to change the NOx from 95% NO +5% NO2 into a mixture of gases containing much more NO2. This brings the regeneration temperature down from the initial 600°C to 275°C.

Full load

Under full load the exhaust temperature easily exceeds this temperature and triggers the regeneration. Once the trap has started regenerating it continues to do so as long as the ceramic honeycomb remains above 275°C, even if the exhaust gas temperature is below that figure.

When the trap is regenerating, incoming particulates are instantly burnt "like snow landing on a pavement", says Galey. While inserting the honeycomb will cause some increase in back pressure, constant regeneration means there is no build-up of carbon. This allows the system to come within the engine manufacturers' back pressure tolerances, Galey explains.

He adds that all this happens without any recourse to electronics. The only drawback is that very low sulphur fuel must be used—to all intents and purposes that means Greenergy. However, Johnson Matthey is working on getting the system to work on the 0.05% sulphur diesel which will come on line next October to coincide with the advent of the Euro-2 emission limit.

This technology will certainly reduce the price of going green; it remains to be seen if the Chancellor will help hauliers absorb that cost by reducing diesel duty...

by Colin Sowinan