• When we buy a car we take it for

Page 39

Page 40

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

granted that its shape has been designed to improve its overall performance. Yet it was not until the early 'eighties that the average family car's air drag coefficient (CD) began to fall below 0.4. Until then, designers were more concerned with asthetics, believing that if it looked right, it (probably) was right.

At about that time, Ford had a bit of a problem with the development of its new truck range. Designed afresh from the inside out, the Cargo cab gave quite a bit more room than the old 1)-Series it eventually replaced — but the frontal area of the vehicle was 17% greater. This increased the CD by almost 5%, and Ford's engineers were fully aware that if nothing was done the new model would be less fuel-efficient than the old.

The company's solution was to fit an under-bumper air dam, designed to reduce air turbulence beneath the vehicle, around the driveline and chassis, which can account for up to 20% of total drag.

The idea worked — and set the scene for Concept Cargo and eventually:or the Windfall Econolite body, which is now built by Bosco and graces the lveco Ford Cargo 1721 we have on test this week.

The gap between the cab and the box has gone: the body blends in with the rear of the Cargo's cab, which incorporates a roof-mounted spoiler. That under-bumper air dam is still there but it has company: side skirts come down well below the level of the load platform, and at the rear a collar extends beyond the roller shutter door to give a clean cut off.

It all looks very tidy, and maybe the adage that if it looks right it is right still works, because Iveco Ford is claiming a Cl) of just 0.5. To put that into perspective, that is about twice as smooth as the best production saloon car, and about 30% better than its conventional box-bodied contemporaries.

The object of the exercise, of course, is to reduce the energy lost to wind resistance and here we might expect gains in specific fuel consumption of about 12%.

Over the past decade, hard-won improvements in engine efficiency have been reducing average fuel consumption by ab out 0.5% a year, so this single aerodynamic innovation could be seen as the equivalent to 24 years of engine development work.

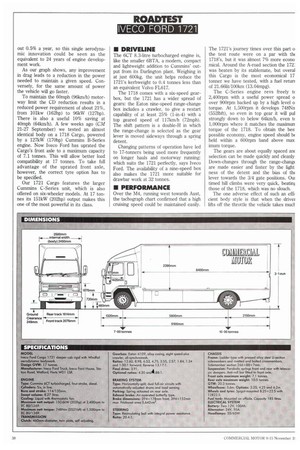

As our graph shows, any improvement in drag leads to a reduction in the power needed to maintain a given speed. Conversely, for the same amount of power the vehicle will go faster.

To maintain the 60mph (96km/h) motorway limit the CD reduction results in a reduced power requirement of about 21%, from 101kw (162hp) to 96kW (127hp). There is also a useful 109k saving at 40mph (641(m/h). A few weeks ago (CM 21-27 September) we tested an almost identical body on a 1718 Cargo, powered by a 127kW (170hp) Cummins 13-Series engine. Now Iveco Ford has uprated the Cargo's front axle to a maximum capacity of 7.1 tonnes. This will allow better load compatibility at 17 tonnes. To take full advantage of the uprated front axle, however, the correct tyre option has to be specified.

Our 1721 Cargo features the larger Cummins C-Series unit, which is also offered on six-wheeler models. At 17 tonnes its 151kW (202hp) output makes this one of the most powerful in its class.

• DRIVELINE

The 6cT 8.3-litre turbocharged engine is, like the smaller 6BTA, a modern, compact and lightweight addition to Cummins' output from its Darlington plant. Weighing in at just 600kg, the unit helps reduce the 1721's kerbweight to 0.4 tonnes less than an equivalent Volvo FL617.

The 1718 comes with a six-speed gearbox, but the 1721 has a wider spread Of gears: the Eaton nine-speed range-change box includes a crawler, to give a restart capability of at least 25% (1-in-4) with a top geared speed of 117km/h (72mph). The shift pattern is a double-H in which the range-change is selected as the gear lever is moved sideways through a spring detent.

Changing patterns of operation have led to 17-tonners being used more frequently on longer hauls and motorway running: which suits the 1721 perfectly, says Iveco Ford. The availability of a nine-speed box also makes the 1721 more suitable for drawbar work at 32 tonnes.

• PERFORMANCE

Over the M4, running west towards Aust, the tachograph chart confirmed that a high cruising speed could be maintained easily. The 1721's journey times over this part o the test route were on a par with th( 1718's, but it was almost 7% more econo mical. Around the A-road section the 172] was beaten by its stablemate, but overal this Cargo is the most economical 17 tower we have tested, with a fuel retun of 21. 661it/100km (13. 04mpg).

The C-Series engine revs freely tc 2,400rpm with a useful power spread o over 900rpm backed up by a high level o torque. At 1,500rpm it develops 748Nn (5521bft), so even in top gear it will pul strongly down to below 641(m/h, even t( 1,000rpm where it matches the maximun torque of the 1718. To obtain the bes. possible economy, engine speed should b( held within a 600rpm band above max imum torque.

The gears are about equally spaced an( selection can be made quickly and cleanly, Down-changes through the range-choig are made easier and faster by the light ness of the detent and the bias of th( lever towards the 3/4 gate positions. Ow timed hill climbs were very quick, beatini those of the 1718, which was no slouch.

The one adverse effect of such an efficient body style is that when the drivel lifts off the throttle the vehicle takes mud longer to slow down. This in turn could put more demand on the service brakes.

During our test of the 1718 we criticised the tide, due in part to poor damping on the front axle. We have no such complaints with the new 7.1-tonne axle, although the suspension (using parabolic springs and an anti-roll bar) looks very similar.

• CAB COMFORT

The Cargo's cab is equipped with a clothtrimmed, air-suspended Bostrom driver's seat with adjustment for weight, height and reach. Although the C-Series engine is larger than the B-Series unit, Iveco Ford has managed to limit the height of the hump, so that cross-cab access is still practical when the driver wishes to dismount from the nearside.

For a cab which is less than full width, this one gives a good impression of roominess, but the size and thickness of the rear bunk does not inspire confidence in its comfort for regular nights out.

A large ratio of glass makes the inside light and allows good all-round vision. Electronics, ever more common in all areas of truck technology, are evident here too. Our Cargo was fitted with a small Mitsubishi TV camera at the rear of the body, linked to a monitor sited between the seats.

When reverse gear is selected the monitor gives a clear view of the scene directly behind the vehicle within 15m, so manoeuvring into a loading bay can be judged precisely. At just under 2900 it is an expensive luxury, but for anyone regularly operating on crowded city streets it will make life easier and safer.

The more conventional instruments are neatly housed in the dished binnacle and, angled at 450, can be easily read through the two-spoked steering wheel.

Substantial rubber mats and plastic trim look as though they will stand up to wear and should be easy to clean. Daily service points are tucked away behind body hatches; the cab tilts to 50°.

III SUMMARY

A quick look at our comparison charts shows how well the 1721 does on performance and body/payload.

Aerodynamic bodywork is much more expensive than a plain box and less convenient when it comes to servicing, but the styling must enhance user's image, and substantial operational savings are possible, thank to the improved aerodynamics.

Fitted with the C-Series engine, the 1721 compares well on carrying capacity with the competition, and where the operation involves a lot of motorway running the larger-capacity engine can combine good journey times with acceptable fuel economy.

Streamlining clearly has great potential which has yet to be fully realised. LI by Bill Brock