REVISIONS PAY OFF

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

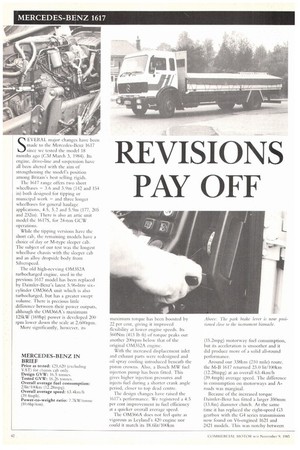

SEVERAL major changes have been made to the Mercedes-Benz 1617 since we tested the model 18 months ago (CM March 3, 1984). Its engine, drive-line and suspension have all been altered with the aim of strengthening the model's position among Britain's best selling rigids.

The 1617 range offers two short wheelbases 3.6 and 3.9m (142 and 154 in) both designed for tipping or municipal work and three longer wheelbases for general haulage applications, 4.5, 5.2 and 5.9m (177, 205 and 232in). There is Also an artic unit model the 1617S, for 24-ton GCW operations.

While the tipping versions have the short cab, the remaining models have a choice of day or M-type sleeper cab. The subject of our test was the longest wheelbase chassis with the sleeper cab and an alloy dropside body from Silverspeed.

The old high-revving 0M352A turbocharged engine, used in the previous 1617 model has been replaced by Daimler-Benz's latest 5.96-litre six. cylinder 0M366A unit which is also turbocharged, but has a greater swept volume. There is precious little .. difference between their power outputs, although the 0M366A's maximum 125kW (169hp) power is developed 200 rpm lower down the scale at 2,600rpin.

More significantly, however, its maximum torque has been boosted by 22 per cent, giving it improved flexibility at lower engine speeds. Its 560Nm (413 lb ft) of torque peaks out another 201rprn below that of the original 0M352A engine.

With the increased displacement inlet and exhaust parts were redesigned and oil spray cooling introduced beneath the piston crowns. Also, a Bosch MW fuel injection pump has been fitted. This gives higher injection pressures and injects fuel during a shorter crank angle period, closer to top dead centre.

The design changes have raised the 1617's performance. We registered a 4.5 per cent improvement in fuel efficiency at a quicker overall average speed.

The 0M366A does not feel quite as vigorous as Leyland's 420 engine nor could it match its 18.61it/100km (15.2mpg) motorway fuel consumption, but its acceleration is smoother and it did produce more of a solid all-round performance.

Around our 338km (210 mile) route. the M-B 1617 returned 23.0 lit/100km (12.28mpg) at an overall 63.4km/h (39.4mph) average speed. The difference in consumption on motorways arid Aroads was marginal.

Because of the increased torque Daimler-Benz has fitted a larger 350nun (13.8in) diameter clutch. At the same time it has replaced the eight-speed G3 gearbox with the G4 series transmission now found on V6-engined 1621 and 2421 models. This was notchy between

third and fourth gears, perhaps owing to the vehicle's newness. Only 12010km (7,5(X) miles) were on the clock.

Neither were gear changes helped by the hydraulically actuated clutch which began to feel a little heavy driving around Cheltenham's ring road.

Three choices of final drive are offered with the haulage models: the 4.75 standard ratio (as tested) and the optional 5.22 and 5.86 to 1. The lower (numerically) final drive gave our test vehicle a rolling gradeability in first gear of 25.5 per cent (1 in 3.9) and a possible maximum geared speed of 105km/h (65mph).

Keeping to the 96km/h (60mph) motorway limit the engine speed holds steady at 2,300rpm, some way above the rev counter's 1,400-2,10Orpm economy band. Running between 64km/h and 80km/h (40 and 50mph) at 1,600 to 1,950 rpm, however, the revs sit nicely in the green segment. This characteristic contributes as much as anything else to the vehicle's excellent A-road and general had efficiency. Climb time over Monmouth hill was on a par with the Leyland Freighter. On Wantage Hill the Mercedes-Benz 1617 lagged behind slightly, hampered by too long a gap between third and second gear. Strong acceleration near the top tempted an over ambitous gear change at about 2.100rpm, which resulted in the revs dropping once inure. brought a hurried down shift and meant keeping to a steady 16km/h (10mph) pull over the severest 1 in 7 in second gear.

Constant cab movement here caused the gear level to vibrate, highlighting a need for better damping on the linkage.

Daimler-Benz never has been renowned for building lightweight trucks and although the 1617 is not likely to break with tradition, there are a number of weight savings. A small one has been made by fitting the compact G4 gearbox with its offset lay shaft and two fewer ratios.

The biggest reduction results from the use of parabolic springs with fewer leaves and at no cost to the 1617's superb ride. Instead of the 10-leaf spring pack at the front there are long, soft three-leaf springs. At the rear the excessive 11-leaf double spring packs have given way to lighter, shackled three-leaf springs with slipper ended three-leaf helpers.

Double-acting shock absorbers and anti-roll bars front and rear remain standard across the range. With the vehicle's rubber bonded front mountings and dampered coil springs at the rear, the standard unsprung seat felt comfortable on most of the route.

In spite of these weight savings, the Mercedes-Benz 1617 chassis cab still overshoots the five tonne mark. On the longest 5.9m wheelbase with the M-type sleeper cab kerb weight is given at 5.43 tonnes, which gives a payload including body allowance of 10.83 tonnes.

At maximum gross weight the 1617's full air brakes react extremely well, feeling soft on initial pressure, but becoming progressively firmer and pulling up sharp on full-pressure stops.

Thankfully, the park brake lever has now been repositioned right at the end of the instrument panel but the exhaust brake button on our test vehicle had not yet been moved from its awkward position close to the seat base.

Heater controls have also beets relocated close to the left side of the instruments.