POWER TO SPARE

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

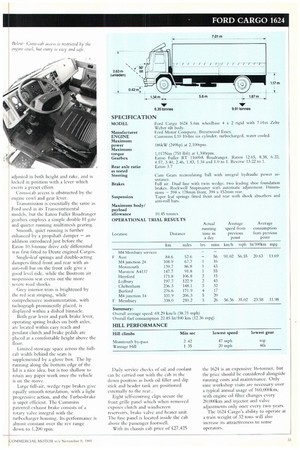

JUST Over a year ago Ford introduced its Cum T11 ins L hi engine Cargo range. When we tested the 3224 tractive unit in the range over the CM Scottish test route it set new fuel consumption standards at 32 tons. So when we were offered a 16-tonner with the same power unit we were very interested to see how such a lightly stressed vehicle would perform.

At first sight, a power rating giving more than twice the required legal minimum power-to-weight ratio might seem excessive. But this vehicle has a design gross train weight (>1 34 tonnes for drawbar application (32 tons is the maximum allowed in the UK). Even then it has power to spare.

The day-cabbed test vehicle with a 5.6m wheelbase is one of five variants ranging from 3.52 to 6.2m. Such was Ford's confidence in the vehicle that it was supplied to us with a German market specification, complete with a Zelte Weber tilt body.

All of the other vehicles included in our group test had either platform or dropside bodies, but any aerodynamic disadvantage of the Cargo's tilt body

was partially offset by a factory fitted roof spoiler and under-bumper air dam. But Ford's engineers did have some. reservations about the choice of axle ratio. Although the 3.7 to 1 ratio axle on our vehicle is an obvious choice for motorway running, the slower 4.33 to 1 ratio is felt to be more suited to the rural A-road sections of the test route.

Such is the power advantage of the 1624 that gearchanging is rarely necessary, except in towns, at roundabouts and road junctions. But despite the vehicle's high power-toweight ratio it was not the quickest of the four models in our test. This may partly be explained, however, by extra caution while driving the left-hooker down many miles (A -narrow twisting lane.

Hill climbing performance, though, is quite exceptional. At Monmouth the Cargo steamed over the crest of' the timed hill climb in top gear at 76km/h (47mph), Even on the 1 in 7 gradient alter Wantage the pace slowed only to 32kin/h (21)oph).

Where the LIO engined 16-tonner really scored was in fuel consumption. It was the most economical vehicle in our group, returning 22.85 lit/100km (12.36mpg).

For optimum fuel economy engine speed must be kept within the 1,500 to 1,800 rpm band. In practice this is fine for motorway and dual carriageway sections, where 1,700 rpm corresponds to 96km/h (60mph) and 1,500 rpm to 80km/h (50mph), but at 64km/h (40mph), while the engine still continues to pull strongly, revs drop to about 1,250 rpm.

The six-cylinder engine is mounted vertically in the chassis frame and fits beneath a floor panel engineered for Perkins' V8 engine — the Cummins L10 unit is considered to be sufficiently quiet to make any extra insulation unnecessary. In-cab noise levels recorded were a comfortable 74.5 dB(A) at 64krn/h, rising to 80 dB(A) at 96km/h, even though the large bore stack is immediately behind the day cab.

Entry to the cab is easy and safe, with two wide steps and a convenient grab handle moulded into the end of the facia panel. The floor, which is covered in thick rubber mats, ends flush with the door seal.

A fully adjustable Bostrom air suspension seat, which remains deflated until the driver is seated, provides extra room for the driver to slide in behind die steering wheel, unimpeded. The standard specification includes the 303 model which has a higher back rest than the one in our test vehicle.

The steering column can also be adjusted in both height and rake, and is locked in position with a lever which exerts a preset effort.

Cross-cab access is obstructed by the engine cowl and gear lever.

Transmission is essentially the same as Ford used in its Transcontinental models, but the Eaton Fuller Roadranger gearbox employs a simple double H gate and quieter running multimesh gearing.

Smooth, quiet running is further enhanced by a propshaft damper an addition introduced just before the Eaton 10.5-tonne drive axle differential was first fitted to Deutz engined Cargos.

Single-leaf springs and double-acting dampers fitted front and rear with an anti-roll bar on the front axle give a good level ride, while the Bostrom air suspension seat evens out the more severe road shocks.

Grey interior trim is brightened by the red seat striping, while comprehensive instrumentation, with tachograph prominently placed, is displayed within a dished binnacle.

Both gear lever and park brake lever, operating spring brakes on both axles, are located within easy reach and pendant clutch and brake pedals are placed at a comfortable height above the floor.

Limited stowage space across the fullcab width behind the seats is supplemented by a glove box. The lip running along the bottom edge of the lid is a nice idea, but is too shallow to retain any paper work once the vehicle is on the move.

Large full-air, wedge type brakes give equally smooth retardation, with a light progressive action, and the Turbo-brake is super efficient. The Cummins patented exhaust brake consists of a rotary valve integral with the turbocharger housing. Its performance is almost constant over the rev range down to 1,200 rpm.

Daily service checks of oil and coolant can be carried out with the cab in the down position as both oil filler and dip stick and header tank are positioned externally to the rear..

Eight self-centring clips secure the front grille panel winch when removed exposes clutch and windscreen reservoirs, brake valve and heater unit. The fuse panel is located inside the cab above the passenger lbotwell.

With its chassis cab price of 07,425 the 1624 is an expensive 16-tonner, but the price should be considered alongside running costs and maintenance. Only nine workshop visits are necessary over a typical annual usage of 160,000km, with engine oil filter changes every 20,000km and injector and valve adjustments only once every two years. The 1624 Cargo's ability to operate at a train weight of 32 tons will also increase its attractiveness to some operators.