"Do It Yot Policy Pays Opera

Page 62

Page 63

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Says Ashley Taylor,

CIRCUMSTANCES attaching to the country-wide operation of heavy 'specialist transport in the Republic of Ireland in the post-war years have combined to provide unusual problems for some operators, a fact that is exemplified in the organization built up by Roadstone, Ltd., Dublin. The name is descriptive and some idea of the company's scale of operations can be obtained from the fact that production and sale of concrete aggregates, roadstone, macadam and mortar are in the region of lim tons a year. The annual mileage averages 50,000 per vehicle.

The fleet and plant are now largely self-sufficient, although only 22 years ago the business comprised a small concrete-block manufacturing plant and retail coal sales yard. The first vehicle was a Model T Ford 1-ton lorry with solid tyres at the rear and pneumatics at the front. After a short time this was traded in and a Ford 30-cwt. lorry was purchased; • later a Morris-Commercial 1-ton . truck was acquired to assist in the deliveries of coal. .

After about three years an American Federal 2-ton truck took , the place of the Ford lorry and the Morris was replaced by a used American Dodge 2-tonner. By this time the business had largely developed into a general haulage concern. The sale of coal was discontinued, but the manufacture and sale of concrete blocks, and the sale of pit run sand and gravel went on. By 1939 the fleet consisted of five Internationals and two Bed fords.

During the war years vehicle fuel was severely rationed in the Twenty-Six Counties, and generally could be obtained only for the transport of fuel and foodstuffs. The work during this period consisted mainly of hauling turf or peat from the bogs located around the centre of Ireland into the city. Mr. Donal Roche, secretary of the company, told me that towards the end of the war the owners decided that they would go into the washed and graded gravel business so as to provide suitable material for the manufacture of concrete blocks.

In 1944 the Castle Sand Co., Ltd.. was formed with a capital of 0,000, the first gravel-washing plant being erected in 1946 at Kill, Co Kildare. This was a Goodwin washing, crushing and screening plant With a capacity of 25 tons per hour. With this capacity available the necessity of additional and More suitable transport immediately arose. Having some 10 years' experience of running comparatively light trucks, and having experienced many difficulties as a result of overloading and overdriving, those in charge decided that in future they would buy vehicles capable of carrying the greatest load at the lowest cost.

The first purchases in the new programme were two Foden oilers, one a six-wheeled tipper and the other an eight-wheeled tipper. Because of the prolonged delivery dates for new vehicles, it was decided to experiment with ex-W.D. chassis which were then selling in great quantities at the Army surplus depots in England. Three Diamond-T 6 x 4 ex-Army tank-recovery vehicles were acquired, afterwards being fitted with I5-cu.-yd. steel tipping bodies and hydraulic tipping gear manufactured in the company's own workshops which had been erected in Tyrconnell Road. These vehicles operated successfully until 1950, when they were sold back to England.

Ten oil-engined Mack N.R.D. 6 x 4 general-service vehicles were purchased and converted into hydraulic tipping lorries, as were six White Cummins oilers and two Federal Cummins.

/shout 1947 a second gravel washing and crushing plant was erected at Bray. Co. Wicklow, with a capacity of about 30 tons per hour. The sale of this material increased rapidly, so that the original plan to develop the old concrete-block manufacturing business was not pursued. Effort was concentrated instead on the production and sale of washed and graded concrete aggregates of all kinds.

The American ex-Army machines generally gave good service. Spare parts were, of course, always difficult to obtain. Some were bought in England and others were purchased direct from the manufacturers in America. As some of the chassis, when acquired, were almost new, and cost as little as £400 at the surplus war material auctions in. England, they were no bad proposition.

Around 1949 the time came to expand the roadstone quarry business. The plans called for a plant capable of processing 100 tons of crushed stone per hour, as well as macadam plant capable of handling 60 tons per hour. These schemes necessitated a large amount of money being found and in 1950 the present public company was floated with a paid-up capital of approximately £300,000.

When the new quarry plant started production in 1952 additional transport was required; the directors also desired to replace all the ex-Army American equipment. Although these units were invaluable during the immediate post-war years, they were completely uneconomic when compared with their modern British counterparts. The foundations of the present fleet were laid in T952, when four Leyland Octopus and four A.E.C. eight-wheeled tipper chassis were delivered.

The main fleet noW consists of 28 Leyland Octopus, 6 Leyland Hippo with trailers, 10 Leyland Comet, 7 A.E.C. units, 2 Foden. 3 Austin-B.M.C. oilers. a Bedford. 6 White c26 dumpers, 2 plant trailers, a Mack breakdown wagon with Leyland supercharged engine, and 11 Mack dumpers, three of which are fitted with blown Leyland power units. Roadstone, Ltd., is at present probably the only operator in the world using Leyland supercharged engines.

Service vehicles include 21 staff cars, a Hillman Husky, a Morris station wagon and a B.M.C. oil-engined van. The plant employed includes a variety of mechanical shovels, rollers, crawler tractors and scarifiers, in addition to three Barber-Greene road finishers.

Commercial vehicles are imported knocked down, the Leylands being assembled by Ashenhurst, Williams and Co., Ltd., Dublin. The A.E.C. units now in the Roadstone fleet were assembled in the company's own workshops. All Roadstone bodywork is built in the company's shops with an Argonarc welder.

The necessary extrusions are bought prefabricated to specification. The manufacture of alloy bodies for the fleet began about six years ago and they are now made in up to 17-ton capacity, this particular size being for the Octopus. Savings in weight as compared with steel arc considerable, especially in the case of trailers, in which bodywork weighing 12 cwt. may accommodate loads as great as 15 tons.

A subsidiary of the company, Tipping Gears, Ltd., Portumna, Co. Galway, makes the only Irish hydraulic tipping gear. The pump and power take-off were initially based, by arrangement, on Pilot designs. Steel and weldedalloy bodies are also made at Portumna.

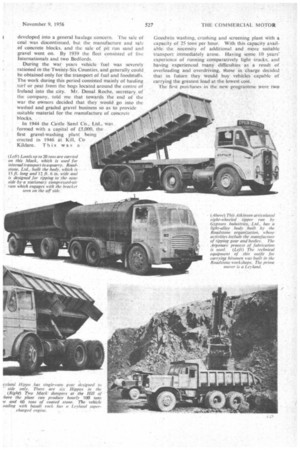

In addition to their normal work, the Dublin body shops were engaged last summer on three special dumpers with Mack chassis. These vehicles are employed at the quarries to move blocks of stone weighing, perhaps, 4-5 tons. Their total capacity is 18-20 tons. After being separated from the rock-face by blasting, the stone has to be carried by these machines to the giant crushers which wait a short distance away. Internally, the steel body is reinforced by transverse bars of railroad section. It is 15 ft. long and 12 ft. 6 in. wide, and is higher on the off side than the near side. There is a prow-shaped retaining contour on the near side.

An unusual arrangement is employed to provide the tipping action. The body is pivoted on the near side, where there are also three faces which, when the vehicle arrives at the crusher, slide on to the top of three corresponding pillars. A stationary compressed-air cylinder is located opposite and this engages with a bracket on the off side of the body, tipping it so that the load is discharged directly into the crusher.

Mention has already been made of premises in Tyrconnell Road, Dublin, which were in use some years ago. Because of expanding business this site became insufficient and the present head office and workshops are situated at Naas Road, on the fringe of the city. A gravel washing and screening plant at Kill. Co. Kildare, has been doubled in size since it was erected in 1946 and has a capacity of 100 tons an hour.

The deposit of gravel in Bray, Co. Wicklow, on which the second Plant was erected in 1947, 'ran ;out, and operations closed down last December. In its place, a graVel washing and streening. plant Ed Kifternan, CO:Dublin, came into action in January of this year and is now in full production

at 100 tons per hour, •

The Hill of Allen Quarry, Co, Kildare, is about 30 miles west of Dublin and comprises a hill of basalt rock covering about 600 acres. 'the quarry plant, which began production in 1952, has a capacity of 100 tons of crushed stone per hour, as well as 60 tons of coated stone. In addition, the corimany operates two dry gravel pits for unwashed sand and gravel. One of these is located at Fassaroe, Bray. Co. Wicklow, and the other. at Blessington. Co. Wicklow. A second roadstone quarry is situated at Tallaght. Co. Dublin. about eight miles from the city. A modern ready-mixed mortar plant has recently been added on a site adjacent to the offices at Naas Road.

Although the various units in the fleet may be scattered as far as Sligo (136 miles). Galway (148 miles), or other distant parts of the land, each must return to Naas Road at night. Whilst certain rules apply to the matter of drivers' hours and rest periods. considerations are rather different

from those in Britain. As each INDICATOR ROD load carrier returns it is an THROUGH CAST

invariable rule that a call shall be made at one of the pits or quarries previously mentioned for the purpose of bringing products to the headquarters plant for delivery the following day in the Dublin district. To assist in maintaining accurate records, Servis clocks are fitted throughout the fleet.

In the office of the transport manager, Mr. Stephen Dunne. wall diagrams show average fuel consumptions. The Foclen, the A.E.C. and the Leyland Octopus machines fall into the 9-10 m.p.g. category, which compares with 7 m.p.g. for the ex-Army American lorries. The Comets, which may make short runs towing tar-sprayers or other equipment for roadsurface layiag. return 13-1g m.p.g.

Drivers Receive Bonuses

Drivers are allocated individual vehicles and eachyear the men who are free from accident receive a bonus. Where minor mishaps. not the result of negligence, have occurred. a percentage of the award may still be paid. To help the staff, which altogether numbers over 300, the company have acquired a.16 mm. projector with which films dealing with the operation and maintenance of vehicles are shown.

Supplying tarmacadam and hiring out road-making equipment is an important branch of the organization's activities and to promote efficiency a two-way radio system has been installed. By this means contact can be maintained between the transmitter at the quarry and the cars of senior members of the staff who go out to inspect the various contracts. Whilst a constant supply of material to the contracts is essential, there is a limit to the time that tarmacadam can be held in the vehicles, so that the speedy transmission of progress reports is invaluable.

The transport workshops are most comprehensive, among their products being the complete technical equipment for a bitumen-carrying Leyland tanker and trailer. In addition to bodybuilding, a wide range of sheet-metal work is carried out, including the manufacture of cabs for the Roadstone fleet. So far as possible all vehicles are fitted with air brakes and air windscreen wipers. What is believed to be the only air-operated traffielndicator has been evolved and is produced 'substantially from electric indicator components_ The air type has been found to be immensely more durable.

Dipculty was experienced at times hi the past as a result of misuse of the batteries employed at the quarries, and to overcome this trouble Ingersoll-Rand air starters have been intrOduced. Each pit has its own compressor syStem and if during the night a compressor tank runs down it can be filled up from the main air supply. On a high percentage • of the fleet Nife batteries are used, the nickel-iron type having been found particularly advantageous. in cold weather. The records suggest that the cost of battery maintenance has been reduced by some 75 per cent. when Nife units have been put into use.

Engine Test and Servicing

An engine test shop, with Heenan and Fronde dynamometer, is in constant employment and here, every, power unit, whether for transport or plant purposes, is tested for

output before being installed.

All the road springs required. for the , fleet tire .made at Naas Road. As an insurance 'against spring failure on arduoUs work. a.second main leaf is inserted and turned over at the ends. A broken main leaf cannot slide out.

Automatic plant is employed in the tyre section for the removal of covers and there is other equipment to assist in their exaMination. There are also machines for curing covers when bursts arc repaired. Tyre pressures of vehicles standing laden overnight are checked twice. Despite the heavy nature Oftheir work, covers used by the Roadstone fleet average 45.000-50,000 miles.

TUBE,

DEATH II

-OPERATED

Dunlop and Goodyear are the makes especially favoured and after full use the covers are retreaded with a bold pattern by the Tyresoies system.

Mileages up to 100.000 arc secured from the brake facings, those of Mintex manufacture usually being employed. , A small bay is devoted to the overhaul of fuel pumps and injectors, the latter being reclaimed on a I-Eartridge bench. Facilities are available in the works for reboring cylinder blocks and the line-boring of engine bearings.

noticed provision for detecting cracks in crankshafts and connecting rods, for valve refacing, for surface grinding and for the rewinding of dynamos and starters. A Lucas beam-setter was seenperforming useful work.

In the transport manager's office the whole fleet is' shown on a wall-board which tabulates each machine from January to December. The needs of each unit in the way of greasing, engine-oil and gear-oil changes, docks, steering-assembly renewals, and springs, injector anti cylinder-head claanges are shown. Every vehicle in the fleet is greased once in three weeks, but for other attention thdperiods vary according to the unit and its duties.

Leyland Octopus engines are drained and refilled with fresh oil each fortnight (or 2,000 miles). The old oil is reclaimed by means of a Stream-Line filter and is employed for such purposes as topping-up tipping gears. Mr. Dunne reports that some of the Leylands have already covered over 200,000 miles and no measurable wear can he discovered on the crankshafts; main and big-end bearings are likewise in perfect condition. Gearbox and differential oil is changed at 25,000 miles. at which stage a light dock takes place, the sump being removed and the oil filter cleaned. At 70.000 miles cylinder

heads anti injectors are renewed. Full overhauls are dependent upon the nature of the work being carried out; 250,000 miles may be regarded as a typical figure. •