Leyland to the Core

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

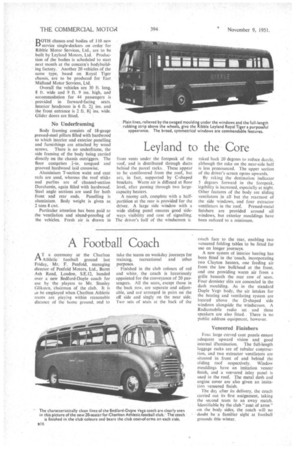

BOTH chassis and bodies of 110-new service single-deckers on order for Ribble Motor Services, Ltd., are to be built by Leyland Motors, Ltd. Production of the bodies is scheduled to start next month at the concern's bodybuilding factory. Another 20 vehicles of the same type, based on Royal Tiger chassis, are to be produced for East Midland Motor Services, Ltd.

Overall the vehicles are 30 ft. long, 8 ft. wide and 9 ft. 9 ins, high, and accommodation for 44 passengers is provided in forward-facing seats. Interior headroom is 6 ft. 21 ins, and the front entrance is 2 ft. 8f ins. wide. Glider doors are fitted.

No Underframing

Body framing• consists of 18-gauge pressed-steel pillars filled with hardwood to which interior and exterior panelling and furnishings are attached by wood screws. There is no underframe, the side framing of the body being carried directly on the chassis outriggers. The floor comprises I-in, tongued and grooved hardwood laid crosswise.

Aluminium T-section waist and cant rails are used, whereas the roof sticks and purlins are of channel-section Duralumin, again filled with hardwood. Steel angle sections are used for both front and rear ends. Panelling is aluminium. Body weight is given as 2 tons 8 cwt.

Particular attention has been paid to the 'ventilation and sound-proofing of the vehicles. Fresh air is drawn in from vents under the forepeak of the roof, and is distributed through ducts behind the parcel racks. These appear to be cantilevered from the roof, but are, in fact, supported by C-shaped brackets. Warm air is diffused at floor level, after passing through two largecapacity heaters.

A roomy cab, complete with a halfpartition at the rear is provided for the driver. A large side window with a wide sliding panel ensures good sideways visibility and ease of signalling. The driver's half of the windscreen is raked back 20 degrees to reduce dazzle, although the rake on the near-side half is less pronounced. The upper section of the driver's screen opens upwards.

By raking the destination indicator 5 degrees forward in the forepeak, legibility is increased, especially at night. Other features of the body are sliding ventilators in all but the rearmost of the side windows, and four extractor

ventilators in the roof. Pressed-metal finishers are provided around all windows, but exterior mouldings have been reduced to a minimum.