Converting a Bus for Rail Work

Page 79

If you've noticed an error in this article please click here to report it so we can fix it.

rOR some time, railway authorities

have been interested in the possibilities of converting the ordinary bus engine and transmission system for use in light railcars on branch lines where traffic does not justify the running of a steam train or an oil-engined railcar. Many experiments in this direction have been carried out, both in Great Britain and the Continent, but the effect of shock on the wheels and bodywork has proved troublesome.

A new invention, recently patented in the joint names of Mr. George B. Howden, chief engineer of the Great Northern Railway of Ireland, and Mr. R. W. Meredith, the company's works manager at Dundalk, utilizes pneumatic tyres in conjunction with the normal steel rail tyres with flanged rims, thus affording a cushioning effect to the whole unit.

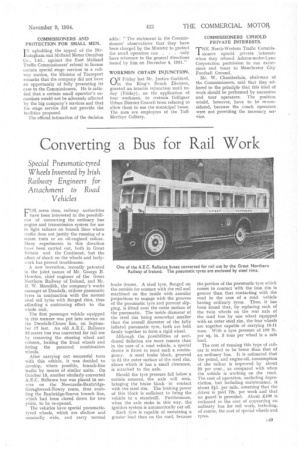

The first passenger vehicle equipped in this manner was put into service on the Dundalk-Clones line, on September 17 last. An old A.E.C. Reliance 32-seater bus was converted for rail use by removing the steering wheel and column, locking the front wheels and fitting the patented combination wheels.

After carrying out successful tests with this vehicle, it was decided to develop, where possible, branch-line traffic by means of similar units. On October 15, another similarly converted A.E.C. Reliance bus was placed in service on the Newcastle-BanbridgeGoraghwood-Newry route, thus enabling the Banbridge-Scarva branch line, which had been closed down for two years, to be re-opened.

The vehicles have special pneumatictyred wheels, which are shallow and unusually wide, and carry normal brake drums. A steel tyre, flanged on the outside for contact with the rail and machined on the inside with annular projections to engage with the grooves of the pneumatic tyre and prevent slipping, is fitted over the outer surface of the pneumatic. The inside diameter of the steel rim being somewhat smaller than the overall diameter of the fully inflated pneumatic tyre, both are held firmly together to form a rigid wheel.

Although the possibilities of accidental deflation are more remote than in the case of a road vehicle, a special device is fitted to meet such a contingency. A steel brake block, grooved to fit the outer surface of the steel rim, above which it has a small clearance, is attached to the axle.

Should the tyre pressure fall below a certain amount, the axle will sink, bringing the brake block in contact with the steel rim. The braking power of this block is sufficient to bring the vehicle to a standstill. Furthermore, when the axle sinks in this way, the ignition system is automatically cut off.

Each tyre is capable of sustaining a greater load than on the road, because

the portion of the pneumatic tyre which comes in contact with the iron rim is greater than that contacting with the road in the case of a road vehicle having ordinary tyres. Thus, it has been found that, by replacing each of the twin wheels on the rear axle of the road bus by one wheel equipped with an outer steel rim, the-four wheels are together capable of carrying 10-11 tons. With a tyre pressure of 100 lb. per sq. in, 3 tons per wheel is a safe load.

The cost of running this type of railcar is stated to be lower than that of an ordinary bus. It is estimated that the petrol, and engine-oil, consumption of the railcar is improved by about 20 per cent., as compared with when the vehicle is working on the road. The cost of operation, excluding depreciation, but including maintenance, is about nth per mile, assuming that the _driver is paid 72s. per week and that no guard is provided. About £100 is redkoned as the cost of converting an ordinary bus for rail work, including, of course, the cost of special wheels and tyres.