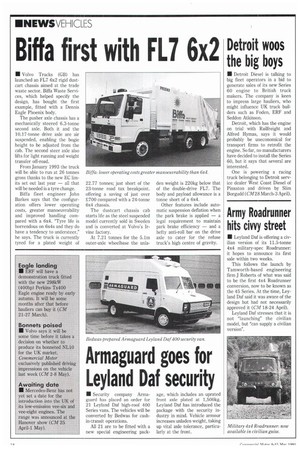

Biffa first with FL7 6x2

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

• Volvo Trucks (GB) has launched an FL7 6x2 rigid dustcart chassis aimed at the trade waste sector. Biffa Waste Services, which helped specify the design, has bought the first example, fitted with a Dennis Eagle Phoenix body.

The pusher axle chassis has a mechanically steered 6.3-tonne second axle. Both it and the 10.17-tonne drive axle are air suspended, enabling the bogie height to be adjusted from the cab. The second steer axle also lifts for light running and weight transfer off-road.

From January 1993 the truck will be able to run at 26 tonnes gross thanks to the new EC limits set out last year — all that will be needed is a tyre change.

Biffa fleet engineer John Barkes says that the configuration offers lower operating costs, greater manoeuvrability and improved handling compared with a 6x4. "Tyre life is horrendous on 6x4s and they do have a tendency to understeer," he says. The truck is currently tyred for a plated weight of 22.77 tonnes; just short of the 23-tonne road tax breakpoint. offering a saving of just over £700 compared with a 24-tonne 6x4 chassis.

The dustcart chassis cab starts life as the steel suspended model currently sold in Sweden and is converted at Volvo's Irvine factory.

At 7.21 tonnes for the 5.1m outer-axle wheelbase the unla den weight is 220kg below that of the double-drive FL7. The body and payload allowance is a tonne short of a 6x4.

Other features include automatic suspension deflation when the park brake is applied — a legal requirement to maintain park brake efficiency — and a hefty anti-roll bar on the drive axle to cater for the refuse truck's high centre of gravity.