70 Series maintains

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

a low profile by Tim Hoare

HEAVY vehicles, of all the modes of transport using air-inflated tyres, have lagged behind in terms making use of sheer tyre technology. Aircraft, for instance, no longer have the enormous tyres used during the last war, and it is a long time since cars were fitted with narrow section 18 or 20in wheels and tyres. In both cases tread life, stability and general safety have improved immeasurably.

For the truck, however, the 20in wheel with a nearly 100 per cent aspect ratio tyre is still in common usage (as it was in the Thirties) and while it is true that the radial and tubeless tyre for heavy vehicles have both definitely arrived (far more so in Great Britain than anywhere else) the truck manufacturing industry seems to be particularly conservative in taking advantage of tyre technology which has been available for some time.

Ever since its introduction in 1970 the Leyland National bus has been equipped with tyres of 70 per cent aspect ratio. Dunlop was instrumental in the basic design of this tyre for the Leyland National, but now several other manufacturers are providing it for Leyland as alternative original equipment suppliers.

For trucks the 70 Series of tyres has many advantages; for the Leyland National the main advantage is the ability to reduce the height of the floor and step because of the tyres' more compact dimensions. In addition to its compact dimensions the 70 Series offers greater wear capability, lower rolling resistance (and therefore improved fuel consumption), improved handling and less weight.

From the outset it was important to design the tyre so that it would fit existing wheels designed for tubeless tyres. Wheels have always been a problem from the-supply point of view and by keeping the same wheel for current and future tyre requirements it is to be hoped that this problem is avoided.

In addition, the width of the tyre had to be kept to the same dimension as existing tyres so that it would fit twin-wheel set-ups without any difficulty.

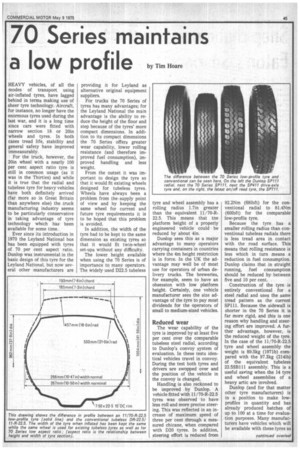

The lower height available when using the 70 Series is of importance to many operators. The widely used D22.5 tubeless tyre and wheel assembly has a rolling radius 1.7in greater than the equivalent 11/70-R22.5. This means that tne platform height of a properly engineered vehicle could be reduced by about 4in.

Dunlop sees this as a major advantage to many operators carrying containers in countries where the 4m height restriction is in force. In the UK the advantage may well be of most use for operators of urban delivery trucks. The breweries, for example, seem to have an obsession with low platform height. Certainly, one vehicle manufacturer sees the size advantage of the tyre to pay most dividends for the operators of small to medium-sized vehicles.

Reduced wear

The wear capability of the tyre is improved by at least five per cent over the comparable tubeless steel radial, according to Dunlop's convoy system of evaluation. In these tests identical vehicles travel in convoy. During the test both tyres and drivers are swopped over and the position of the vehicle in the convoy is changed.

Handling is also reckoned to be improved by Dunlop. A vehicle fitted with 11 /70-R-22.5 tyres was observed to have less roll and more precise steering. This was reflected in an increase of maximum speed of three per cent through a measured chicane, when compared with D20 tyres. In addition, steering effort is reduced from

92.2Nm (681bft) for the conventional radial to 81.4Nm (601bft) for the comparable low-profile tyre.

Because the tyre has a smaller rolling radius than conventional tubeless radials there is less tread area in contact with the road surface. This means that rolling resistance is less which in turn means a reduction in fuel consumption. Dunlop claims that in straight running, fuel consumption should be reduced by between five and 10 per cent.

Construction of the tyre is entirely conventional for a steel radial and uses the same tread pattern as the current SP111. Because the sidewall is shorter in the 70 Series it is far more rigid, and this is one reason why handling and steering effort are improved. A further advantage, however, is the reduced weight of the tyre. In the case of the 11/70-R-22.5 tyre and wheel assembly the weight is 89.5kg (1971b) compared with the 97.3kg (2141b) of the equivalent tubeless 22.5SB1 1 1 assembly. This is a useful saving when the 14 tyre and wheel assemblies of a heavy artic are involved.

Dunlop (and for that matter other tyre manufacturers) is in a position to make lowprofiles in quantity and has already produced batches of up to 100 at a time for evaluation purposes. Many manufacturers have vehicles which will be available with these tyres as

an option, but it seems that it will be another 18 months at least before any of them become available to the operator.

One important change for any vehicle fitted with 70 Series tyres in place of current tubeless tyres (which have an aspect ratio of about 87 per cent) is the incorporation of a different final ratio to counteract the effects of the smaller rolling radius.

The 70 Series has been designed for recutting and remoulding and a good tread life should therefore be expected.

Another important area of development relies on a new synthetic fibre from Du Pont in the United States. Called Kevlar, the new material is the first to be developed specifically for the tyre industry and has properties, in tension, very similar to steel.

No rusting

One of the major problems with using steel as bracing in the sidewalls of radial tyres is that of rust. In many instances a tyre that would normally be acceptable for remoulding fails because of a small puncture in the sidewall which has let in moisture and caused rust. With Kevlar, however, this problem does not arise and it is seen by Dunlop as providing the basis for a very good remouldable tyre. Another paint in its favour is its weight when compared with steel and also the fact that it is far easier to work with than steel bracing, during manufacture.

Already some racing motorcycle tyres are in use having Kevlar in place of steel bracing. The only problem seems to be one of supply from the United States.

It seems unlikely that truck tyres will become any more "low profile" once the 70 Series really gets going, and it is improbable that 65 or 60 per cent tyres will be developed for trucks in the same way that they have been for cars. It must be remembered, however, that a few years ago tubeless tyres for trucks were virtually unknown, and yet now some 70 per cent of new trucks being delivered in the UK are on tubeless tyres.

At the moment 70 Series tyres could be available as original equipment in the sizes, 9/70-R-22.5, l0/70-R22.5, 22.5, H/70-R-22.5 and for Continental operators in the sizes 12/70-R-22.5 and 13/70R-22.5.