Bigger Dumpmaster body

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

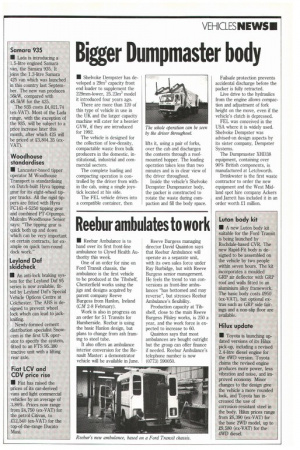

• Shelvoke Dempster has developed a 29m3 capacity front end loader to supplement the 229mm-lower, 25.23m3 model it introduced four years ago.

There are more than 120 of this type of vehicle in use in the UK and the larger capacity machine will cater for a heavier GVW, if they are introduced for 1992.

The vehicle is designed for the collection of low-density, compactable waste from bulk producers in the domestic, institutional, industrial and commercial sectors.

The complete loading and compacting operation is controlled by the driver from within the cab, using a single joystick located at his side.

The FEL vehicle drives into a compatible container, then

lifts it, using a pair of forks, over the cab and discharges the contents through a roofmounted hopper. The loading operation takes less than two minutes and is in clear view of the driver throughout.

Inside the vehicle's Shelvoke Dempster Dumpmaster body, the packer is constructed to rotate the waste during compaction and fill the body space. Failsafe protection prevents accidental discharge before the packer is fully retracted.

Live drive to the hydraulics from the engine allows compaction and adjustment of fork height on the move, even if the vehicle's clutch is depressed.

FEL was conceived in the USA where it is widely used. Shelvoke Dempster was advised-on design aspects by its sister company, Dempster Systems.

The Dumpmaster XHD38 equipment, containing over 90% British components, is manufactured at Letchworth.

Drinkwater is the first waste contractor to order the new equipment and the West Midland spot hire company Ackers and Jarrett has included it in an order worth El million.