The pantechnicon gets a new image

Page 31

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

2ATCH sight of Vanplan's latest design of furniture removal van In your rear-view mirror on the motorway and you might easily mistake it for one of those twindeck luxury coaches that glide along in the outside lane. That is because the top-of-the-range ARZ model owes its very existence to observations made by one of the specialist bodybuilder's main customers in the passenger transport hall at the 1982 Motor Show.

Looking at the stylish lines of the luxury continental tourers on display, Aubrey Appleton, managing director of Giltspur Bullens Transport Services, thought that a large removal van built with a similar frontal style would project the company's image well. So he asked Vanplan's managing director Arthur Brown if he could produce one.

The major stumbling block was not the design work, but the high price of the large curved windscreens which ran to about £1,200 for the pair. To overcome this Mr Brown decided to use his standard GM windscreens, reducing the cost to about £200. The move made the ARZ an entirely viable proposition, and the prototype appeared the following May.

To accommodate the cheaper panes yet still present the illusion of a deeply glazed front, Vanplan produced a new design of forward panel. With the lower portion blacked out, the bottom windscreen appears to be much deeper than it actually is.

Above the driving compartment the frontal area curves backwards and has angled windows at the sides as well as the upper screen.

Using the Luton top space in this way reduces body capacity by around 8.4cum (300cuft), but provides accommodation for six men as well as the driver and two below. This eliminates the need for an accompanying minibus to transport a removal team, which is often the case with complicated office moves, computer department transfers or company executive removals.

Vanplan's latest front end package also included a redesigned instrument panel, a moulded bumper surround, scooped air dam and cab doors with electric windows. The stylish appearance of ARZ-fronted vehicles reflects a professional image, which is particularly useful for prestigious contract work.

Warrington-based Vanplan is a relative newcomer to bodybuilding, but that is certainly proving to be no handicap. The company was founded 12 years ago by Arthur Brown, Arthur Rathbone and Gerry Grove (who has since left the company). All had many years of body and coach building experience.

Mr Rathbone is now retired, but he still holds the brief on design work, in particular on the ARZ designs which carry his initials.

Both directors are emphatic about the advantage of glass reinforced bodies over aluminium, and indeed the company specialises in that medium. "On average an alloy body may be up to £7 0 0 cheaper," says Mr Brown, "but glass fibre ones are much more durable, easier to repair, inert to weather conditions and flexible."

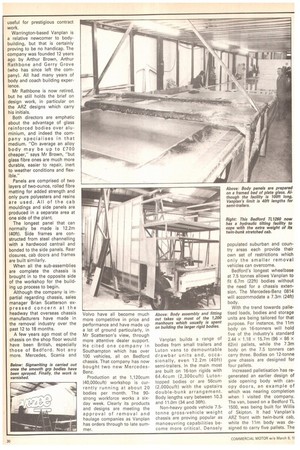

Panels are comprised of two layers of two-ounce, rolled fibre matting for added strength and only pure polyesters and resins are used. All of the cab mouldings and side panels are produced in a separate area at one side of the plant.

The longest panel that can normally be made is 12.2m (40ft). Side frames are constructed from steel channelling with a hardwood cantrail and bonded to the side panels. Rear closures, cab doors and frames are built similarly.

When all the sub-assemblies are complete the chassis is brought in to the opposite side of the workshop for the building up process to begin.

Although the company is impartial regarding chassis, sales manager Brian Scatterson expressed concern at the headway that overseas chassis manufacturers have made in the removal industry over the past 12 to 18 months.

A few years ago most of the chassis on the shop floor would have been British, especially those of Bedford. Not any more. Mercedes, Scania and Volvo have all become much more competitive in price and performance and have made up a lot of ground particularly, in Mr Scatterson's view, through more attentive dealer support. He cited one company in Southampton which has over 100 vehicles, all on Bedford chassis. That company has now bought two new MercedesBenz.

Production at the 1,120cum (40,000cuft) workshop is currently running at about 20 bodies per month. The 90strong workforce works a sixday week. Clearly its products and designs are meeting the approval of removal and haulage companies as Vanplan has orders through to late summer. Vanplan builds a range of bodies from small trailers and Luton vans to demountable drawbar units and, occasionally, even 12.2m (40ft) semi-trailers. In the main most are built on 16-ton rigids with 64.4cum (2,300cuft) Luton topped bodies or are 56cum (2,000cuft) with the upstairs double-bunk arrangement.

Body lengths vary between 10.3 and 11.0m (34 and 36ft). Non-heavy goods vehicle 7.5 tonne gross-vehicle weight chassis are proving popular as manoeuvring capabilities become more critical. Densely populated suburban and country areas each provide their own set of restrictions which only the smaller removal vehicles can overcome.

Bedford's longest wheelbase at 7.5 tonnes allows Vanplan to fit 6.7m (22ft) bodies without the need for a chassis extension. The Mercedes-Benz 0814 will accommodate a 7.3m (24ft) body.

With the trend towards palletised loads, bodies and storage units are being tailored for that purpose. For instance, the 11m body on 16-tonners will hold five of the industry's standard 2.44 x 1.18 x 15.7m (96 x 86 x 62in) pallets, while the 7.3m body on the 7.5 tonners can carry three. Bodies on 12-tonne gvw chassis are designed for four pallets.

Increased palletisation has regenerated an earlier design of side opening body with can opy doors, an example of which was nearing completion when I visited the company. The van, based on a Bedford TL 1500, was being built for Willis of Skipton. It had Vanpian's ARZ 'front with twin-bunk cab, while the 11rn body was designed to carry five pallets. The nearside doors had flaps which opened to form a floor supported by pull-out beams that could support the weight of two men.

Another example, mounted on a Mercedes-Benz 1617 chassis for Pearson of Middlesbrough, had a 56curn Luton body with a recess in the overhang to allow the cab to tilt a full 65 degrees for maintenance. Just behind the cab, narrow steps lead up to the top deck which combines cooking and sleeping facilities for a twoman crew with space for an occasional third man.

Maintenance is always a problem on this type of body and, like all other body builders, Vanplan tries to offer maximum access. The company has included the hydraulic tilt facility on a stretched TL1630 cab which also has a double sleeper top deck. Access is sufficient to allow most major repair work on the engine.

Mr Brown and his management team keep in touch with customers by involving the company actively with the British Association of Removers. It was at one of the BAR's bi-annual meetings last year that concern was expressed by chairman Phil Reading about the lack of training within the association.

As a result, Vanplan's managing director took up the idea and produced a £40,000 purpose-built training vehicle on a donated Bedford TL 1630 chassis for use by the BAR. With an ARZ front, the first half of the body functions as a classroomcum-hospitality suite. Behind the partition, the rearmost 3.7m (12ft) long section carries quality furniture items and is used for practical training sessions.

The vehicle also has a side door with a locker under the step and one pallet crate carried forward of the wheel box. Rear loading is by means of a covered walk-in tailboard.

Looking ahead, Mr Brown sees more use being made of containerised loads and demountable drawbar units, but certainly nothing more dramatic than that. When he says that the vehicles people are buying today will still be around at the start of the next century it is clear that he means vehicles fitted with Vanplan bodies,