The Tiger Cub

Page 60

Page 61

Page 62

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

By A. A. TOWNSIN, A.M.I.Mech.E.

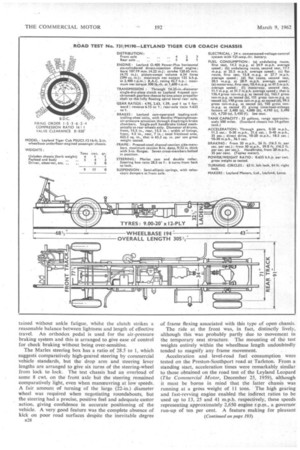

TRAVELLING at 65 m.p.h. on an open chassis immediately after a period of heavy rain is more akin to motorcycling than the type of travel normally associated with a motor coach. I think that the future passengers to be carried by the Leyland Tiger Cub recently tested will, on balance, be better off than I was, although they will certainly miss an exhilarating experience. , The chassis was an example of the coach version, model PSUCI.12, of the latest series, with Leyland 0.400 PowerPlus 6.54-litre engine in place of the earlier 0.350 5.76-litre unit, and was one of 60 ordered by the Ulster Transport Authority. The specification also included a four-speed synchromesh gearbox and single-speed rear axle with a ratio of 4.625 to I. The former, derived from the unit used in the Titan PD2 double-decker, is now a production alternative to the five-speed constant-mesh gearbox of Albion origin, whilst a two-speed axle with ratio of 4.89 and 6.8 to 1 continues to be available. Alternative ratios for the single-speed rear axle are 4.111, 5.143 or 6.166 to 1.

The U.T.A. requirements also included a 33-gal. fuel tank in place of the standard 24-gal. type, whilst the spare wheel. carrier normally mounted just ahead of the nearside rear wheel on the coach version of the Tiger Cub was dispensed with. The bus version of the same chassis, with full-length frame, is designated PSUC1.11, whilst an equivalent model with Pneurno-Cyclic four-speed box is the PSUC1.13. The foregoing all have right-hand controls whereas the LOPSUC1.11, a bus chassis with constantmesh or synchromesh gearbox, and the LOPSUC1.12, a coach model with Pneume-Cyclic gearbox, have left-hand controls.

The 0.400 Power-Plus engine. gives 19 per cent. more power than the 0.350. The earlier unit's maximum net output of 105 b.h.p. at 2,400 r.p.m. has been increased to 125 b.h.p. at the same speed. It is interesting to note that the b.h.p. figure is thus exactly the same as that of the Leopard with 0.600 9.8-litre engine, although in the latter case the speed at which this is developed is 1,800 r.p.m. The maximum torque of the Tiger Cub engine in latest form is 300 lb ft. at the relatively high speed for an engine of this type of 1,600 r.p.m., the previous figure being 255 lb.-ft. at 1,400 r.p.m., whilst that for the Leopard is 410 lb-ft. at 900 r.p.m.

The comparison with the Leopard is of particular interest because its chassis, in the form intended for 30-ft. long bodywork, is very similar to that of the Tiger Cub, apart from the power unit. The designed maximum gross weight for the PSUC1.12 is 9 tons 10 cwt. and with crew the test chassis weighed I cwt. in excess of this.

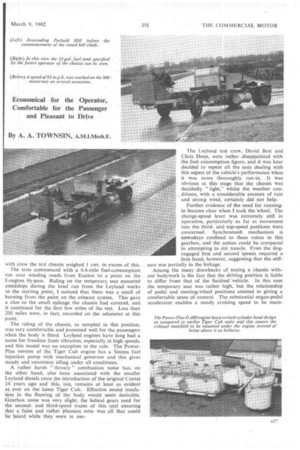

The tests commenced with a 9.4-mile fuel-consumption run over winding roads from Euxton. to a point on the Longton 13y-pass. Riding on the temporary seat mounted amidships during the brief run from the Leyland works to the starting point, I noticed that there was a smell of burning from the paint on the exhaust system. This gave a clue to the small mileage the chassis had covered, and it continued for the first few miles of the test. Less than 200 miles were, in fact, recorded on the odometer at this point.

The riding of the chassis, as sampled in this position, was very comfortable and promised well for the passengers when the body is fitted. Leyland engines have long had a name for freedom from vibration, especially at high speeds, and this model was no exception to the rule. The PowerPlus version of the Tiger Cub engine has a Simms fuel injection pump with mechanical governor and this gives steady and consistent idling under all conditions.

A rather .harsh " throaty " combustion noise has, on the other hand, also been associated with the smaller Leyland diesels since the Introduction of the original Cornet 14: years ago and this too, remains at least as evident as ever on the latest Tiger Cub. Effective Sound insuld'Lion in the flooring of the body Would seem dekirable. Gearbox noise was very slight, the helical gears used for the 'secondand third-speed trains of this unit ensuring that a faint and rather 'pleasant Mite WaS -all that Could be heard while they were in use.

The Leyland test crew, David Best and Chris Dean, were rather disappointed with the fuel consumption figure, and it was later decided to repeat all the tests dealing with this aspect of the vehicle's performance when it was more thoroughly, run-in. It . was obvious at this stage that the chassis was decidedly "tight," whilst the weather con

ditions, with a considerable amount of rain and strong wind, certainly did not help.

Further evidence of the need for runningin became clear when I took the wheel. The change-speed lever was extremely stiff in operation, .particularly so far as movement into the thirdand top-speed poSitions were concerned. Synchromesh mechanism is nowadays confined to these ratios in this gearbox, and the action could be compared to attempting to stir treacle. Even the dogengaged first and second speeds required a firm hand, however, suggesting that the stiffness was partially in the linkage.

Among the many drawbacks of testing a chassis without bodywork is the fact that the driving position is liable to differ from that of the finished 'vehicle. In this case the temporary seat was rather high, but the relationship of pedal and steering-wheel positions assisted in giving a comfortable sense of control. The substantial organ-pedal accelerator enables a steady cruising speed to be main tamed without ankle fatigue, whilst the clutch strikes a reasonable balance between lightness and length of effective travel. An orthodox pedal is used for the air-pressure braking system and this is arranged to give ease of control for check braking without being over-sensitive.

The Marks steering box has a ratio of 28.5 to 1, which suggests comparatively high-geared steering by commercial vehicle standards, but the drop arm and steering lever lengths are arranged to give six turns of the steering-wheel from lock to lock. The test chassis had an overload of some 8 cwt. on the front axle but the steering remained comparatively light, even when manceuvring at low speeds. A fair amount of turning of the large (22-in.) diameter wheel was required when negotiating roundabouts, but the steering had a precise, positive feel and adequate castor action, giving confidence in accurate positioning of the vehicle. A very good feature was the complete absence of kick on poor road surfaces despite the inevitable degree 1128 of frame flexing associated with this type of open chassis.

The ride at the front was, in fact, distinctly lively, although this was probably partly due to movement in the temporary seat structure The mounting of the test weights entirely within the wheelbase length undoubtedly tended to magnify any frame movement.

Acceleration and level-road fuel consumption were tested on the Preston-Southport road at Tarleton. From a standing start, acceleration times were remarkably similar to those obtained on the road test of the Leyland Leopard (The Commercial Motor, December 25, 1959), although it must be borne in mind that the latter chassis was running at a gross weight of 11 tons. The high gearing and fast-revving engine enabled the indirect ratios to be used up to 13, 25 and 41 m.p.h. respectively, these speeds representing approximately 2,650 engine r.p.m., a governor run-up of ten per cent. A feature making for pleasant driving when the performance was being used to the full was the smooth and gradual governor cut-off.

Lively top-gear acceleration from 10 m.p.h. was too much to expect from a vehicle geared to run at 24.7 m.p.h. at 1,000 engine r.p.m. in this ratio, particularly when barely run-in. It was evident, as the speed was allowed to drop before commencing each run, that the idling range of the governor was being reached. There was slight transmission rattle under these conditions, but this ceased as soon as power was applied. Acceleration was smooth but sluggish up to about 14 m.p.h., when the engine note " sharpened " and a definite surge of power was felt.

A 17-mile high-speed motorway run on the Preston by-pass was made at an average speed of 47.5 m.p.h., the maximum speed reached on down-grades and maintained on the level being 65 m.p.h. The minimum speed up one of the hills, reputed to have a 1-in-23 gradient, was 32 m.p.h., although the chassis was baulked and brought down to about 10 m.p.h. momentarily white negotiating the roundabout at the northern end.

The following morning was dry and bright, and this enabled the brakes to be tested. Both rear wheels locked on every occasion, but the chassis showed no tendency to depart from a straight course. Some delay in build-up of air pressure was detectable, but at 30 m.p.h. the difference between the total stopping distance and the length of the skid marks was 20 ft., both when I drove the chassis and when David Best did so, suggesting that it amounted to less than half a second. The front of the chassis tended to hop, but the front wheels showed no sign of locking. A Tapley meter reading of 100 per cent. was recorded, suggesting that some surge may have occurred. There was certainly no lack of braking power. Handbrake efficiency, was limited by the frame of the temporary seat which restricted the movement of the lever. Even so, consistent figures of, 35 per cent, are very satisfactory. • • A Fast Climb The chassis appeared to have become more free-running and an exceptionally fast climb of the 1-mile-long Parbold Hill, occupying 2 minutes 45 seconds, was made. Most of the climb, with its average gradient of I in 12, was made at or near peak revs in second gear. First gear was required for 20 seconds when the steepest part of the climb, with a gradient of approximately 1 in 61, was reached. The ambient temperature was 5.5°C. (42°F.) and with a blanking plate covering half the radiator area the coolant temperature rose from 71°C. (160°F.) to 77°C. (170°F.), which indicated that there was ample cooling capacity.

A brake fade test was carried out by descending the hill in neutral and using the footbrake to keep the speed down to 20 m.p.h. I rather expected that, quite apart from fade effects, some drop in the reseryoir air pressure would result from the frequent, if slight, movements of the brake pedal which I was unable to prevent on the descent because of the somewhat uneven road surface. I was agreeably surprised, therefore, when a full brake application at the foot of the hill produced a reading of 100 per cent, on the Tapley meter. A very slight smell of hot linings could be detected but this braking system, originally designed for a heavier chassis, is not likely to fade appreciably in normal use, even in very hilly territory. A gauge had been fitted to record the line pressure to the brake chambers, and it was interesting to note that normal check braking required a mere 10 p.s.i.

Returning up the hill and stopping on the 1 in 61 gradient it was found that the handbrake would hold the vehicle with ease. A restart in first gear was made without difficulty, althoughit was clear that there was not an unlimited reserve of power. The combination of gearbox and axle ratio of the chassis tested was not ideal for steep hills, of course, and a vehicle likely to have to climb more severe gradients should be fitted with a gearbox or rear axle giving a greater reduction in the lowest ratio.

Returning to repeat parts of the test a fortnight later, I found that the recorded mileage had been increased to just under 1,000. No mechanical modifications had been made, but in the course of checking over the engine a defective injector, which tended to misbehave at part throttle, had been discovered. The temporary seat mounted amidships, as shown in the illustrations, had been removed, however, and this reduced the weight by 1 cwt. 3 qtr. as well as probably reducing the wind resistance somewhat. The weather, cloudy but dry, was more favourable on this occasion than during the earlier fuel-consumption tests.

On the road, the easier running of the chassis was obvious, even from the passenger's seat. The cross-country fuel consumption run from Euxton to the Longton by-pass was the first to be repeated. Although the cruising speed set for the run, about 32 m.p.h., was unchanged, less traffic delays were experienced, and the average speed was 25.5 m.p.h., compared with 24.9 m.p.h. on the earlier occasion. The fuel consumption was reduced appreciably from the earlier figure of 14.3 m.p.g. to 17.1 m.p.g.

Level-road fuel consumption tests were again carried out on a 5.95-mile course at Tarleton. This involved travelling over a stretch of dual carriageway in both directions, with a roundabout at one end, reversing direction at the other end by negotiating a break in the central dividing strip. Most of the coursecan be traversed at constant speed, and 30-32 m.p.h. was set as the target.

Again, luck with traffic produced a faster time than on the previous occasion, and the run could very nearly be taken as a constant-speed test at 30 m.p.h. The very creditable figure of 20.1 m.p.g. was reached, showing an improvement of some 28 per cent. over the earlier figure.

A repeat of the top-gear acceleration tests showed, that performance had also improved. The engine pulled strongly from 10 m.p.h. on this occasion, reaching 20 m.p.h. in 18.5 seconds, an improvement of 3.5 seconds on the previous time, whilst 30 m.p.h. was reached in 38 seconds, representing a reduction of 6.6 seconds on the earlier test. The acceleration times from a standing start were not repeated, partly due to lack of time, as it was felt that they were less likely to be affected to such an extent, although a second or two might have been clipped off them,

The motorway run was also appreciably faster, and although this was partly due to being able to negotiate the roundabout at the north end without delay, the minimum climbing speed was 43 m.p.h. The maximum speed was unchanged at 65 m.p.h. and on this occasion, with a half-blanked radiator, the maximum coolant temperature was 79.5°C. (175°F.), showing that ample cooling capacity was available under these conditions. The fuel consumption, 11.1 m.p.g., did not show as great an improvement over the earlier figure of 10.4 m.p.g. as on the slower speed tests, but the improvement in average speed from 47.5 m.p.h. to 51.7 m.p.h. must be borne in mind The second series of tests showed that, even with modern production methods, at least 1,000 miles of normal running may be required to allow a vehicle to develop something approaching its best performance. The Tiger Cub is shown to be a very economical model, particularly if its performance is not used to the full. Operators requiring high performance would probably find that the Leopard model would give comparable economy with the effortlessness of a larger engine. The Tiger Cub appears to be very well suited to work where economy is of paramount importance and schedules allow moderate speeds to be used.