For DRIVERS, MECHANICS & FOREMEN.

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter SHILLINGS to the sender of the one which we select as published. Mention your employer's name, in confidence, Commercial Motor," 745, Bos which we publish on this page, and an EXTRA FIVE being the best each week. All notes are edited before being as evidence of good faith, Address, D., M. and F., "The ebery Avenue, London, E.C. 1.

On Saturday, March lath, light your lamps at 6.26 in London, 6.45 in Edinburgh, 6.36 in Newcastle, 6.42 in Liverpool, 6.36 in Birmingham, 6.39 in Bristol, and 7.25 in Dublin.

Repairing a Flywheel.

The sender of the following communication has been awarded the extra payment of 5s. this week.

12,063] " F.W." (Barrow) writes There are very

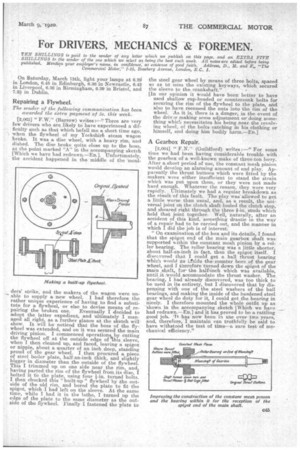

few drivers who are likely to have experienced a difficulty such as that which befell me a short time ago, when the flywheel of my Yorkshirt steam wagon broke. It was a disc wheel, with a heavy rim, and dished. The diso broke quite close up to the boss, at the point marked "A" in the accompanying sketch [Which we have had redrawn—En.]. Unfortunately, the accident happened in the middle of the moul

ders' strike, and the makers of the wagon were unable to supply a new wheel. I had therefore the rather unique experience of having to find a substitute for a flywheel, or else to devise means of repairing the broken one. Eventually I decided to adopt the latter expedient, and ultimately I managed all right, as a further glance at the sketch will show. It will be noticed that the boss of the flywheel was extended, and on it was secured the main driving pinion. I commenced operationby cutting the flywheel off at the outside edge of This .sleeve, when I then cleaned up, and faced, leaving a spigot or nipple, about a quarter of an inch deep, standing proud of the gear wheel. I then procured a piece of steel boiler plate, half-an-inch thick, and slightly bigger in diameter than the outside of the flywheel. This I trimmed up on one side near the rim, and, having parted the rim of the flywheel from its disc, I bolted it to the plate, using four 1-in. turned bolts. I then chucked this built-up " flywheel by :the outside of the old rim, and bored the plate to fit the spigot, which I had left on the sleeve. At. the same time, while I had it in the lathe, I turned up the edge of the plate to the same diameter as the outside of the flywheel. Finally I fastened the plate to the steel gear wheel by means of three bolts, spaced so as to miss the existing keyways, which secured the sleeve to the crankshaft."

fIn our opinion it *mild have been better to have used shallow cup-headed or countersunk bolts for securing the rim of the flywheel to the plate, and also to have recessed the nuts into the rim of the wheel. As it is, there is a danger, in the event of the drivir making some adjustment or doing something which necessitates his being near the revolving wheel, of the bolts catching in his clothing or himself, and doing him bodily harm.---En.]

A Gearbox Repair.

[2,064] " F.N." (Guildford) writes :—" For some time we had been having considerable trouble with the gearbox of a well-known make of three-ton lorry. After a short period of use, the constant mesh. pinion would develop an alarming amount of end play. Apparently the thrust buttons which were fitted by the makers were either insufficient to stand the strain which was put upon them, or they were not made hard enough. Whatever the reason, they wore very rapidly. Lltimately we had a regular breakdown an the rbsult of this fault. The play was allowed to get a, little worse than usual, and, as a result, the universal joint on the clutch shaft fouled the clutch stop, and sheared right through the three 1-in, studs which held that joint together. Well, naturally, after an accident of this kind, something drastic in the way of a repair had to be carried out, and the manner in which I did the job is of interest.

"On examination.of the box and its details, I found that the spigot end of the main gearbox shaft was supported within the constant mesh pinion by a roller bearing. The roller bearing was a little shorter, about half-an-inch in fact, than the spigot itself. di9.ccvered that I could get a ball thrust bearing which would gQ hIside the counter bore of the gear wheel, and I therefore turned down the spigot of the main shaft, furthe halflinch which was available, until it .would.accommodate the thrust washer. The bearing, I had already discovered, was too thick to be used in its entirety, but I discovered that by dispensing with one of the steel washers of the ball bearings, and snaking the inside of the hardened steel gear wheel do duty for it, I could get the bearing in nicely. I therefore mounted the whole outfit up as -shown in the accompanying sketch I.Whieh we have had redrawn.—En.] and it has proved to be a rattling .good job.. 'It has now been in use over two years, and, therefore, I maintain can truthfully be said to have withstoOd the test of time—a sure test of me

chanical efficiency." '