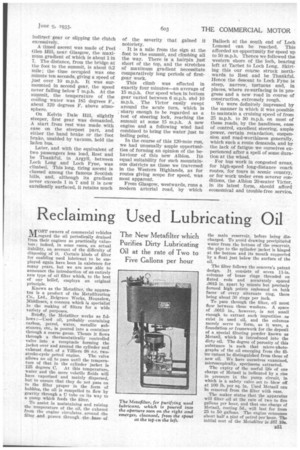

Reclaiming Used Lubricating Oil

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

OST owners of commercial vehicles IV_Lregard the oil periodically drained from their engines as practically valueless; indeed, in some cases, an actual liability, on account of the difficulty of disposing of it. Certain kinds of filter for enabling used lubricant to be employed again have been in existence for many years, but we are now able to announce the introduction of an entirely new type of oil filter which, to the best of our belief, employs an original principle.

Known as the Metafilter, the apparatus is a product of the Metafiltration Co., Ltd., Belgrave Works, Hounslow, Middlesex, a concern which is specialist in the making of filters for a wide variety of purposes.

Briefly, the Metafilter works as follows :—.Used oil, probably containing carbon, petrol, water, metallic substances, etc., is poured into a container through a coarse gauze. Thence it flows through a thermostatically controlled valve into a receptacle forming the jacket over and around the cylinder and exhaust duct of a Villiers 98 c.c. two

stroke-cycle petrol engine. The valve allows no oil to pass until the temperature of that in the cylinder jacket is 125 degrees C. At this temperature, water and the more volatile fluids will have vaporized and mainly dispersed, but to ensure that they do not pass on to the filter proper in the form of bubbles, the oil is compelled to flow by gravity through a T_T tube on its way to a pump which feeds the filter.

To assist in maintaining and raising the temperature of the oil, the exhaust from the engine circulates around the filter and passes through the base of

the main reservoir, before being discharged. To avoid drawing precipitated water from the bottom of the reservoir, the pipe to the cylinder jacket is hinged at the bottom and its mouth supported by a float just below the surface of the oil.

The filter follows the concern's patent design. It consists of seven 11-in. columns of brass rings threaded on fluted rods and accurately spaced .0015 in. apart by minute but precisely formed high points embossed on both faces of every alternate ring, there being about 30 rings per inch.

To pass through the filter, oil must flow between these washers. A space of .0015 in., however, is not small enough to extract such impurities as exist in used oil, and the columns merely serve to form, as it were, a foundation or framework for the deposit of a special filtering powder 'blown as Metasil, which is introduced into the dirty oil. The degree of porosity of this substance is such that micro photographs of the oil emerging from the filter cannot be distinguished from those of new oil. We have ourselves examined, microscopically, specimens extracted.

The expiry of the useful life of one charge of Metasil is indicated by a rise in pressure in the pump circuit, in which is a safety valve set to blow off at 100 lb. per sq. in. Used Metasil can be removed from the filter with ease.

The maker states that the apparatus will filter oil at the rate of two to five gallons per hour, and that one charge of Metasil, costing 5d., will last for from 25 to 50 gallons. The engine consumes about half a pint of petrol per hour. The initial cost of the Metafilter is £67 10s.