Braking by wire

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

Truck manufacturers are already using electronics to control the application of air brakes in ABS. But what about electronically activated brakes?

• Like it or not, truck operators will have to get used to electronically controlled brakes. But what about electronically activated brakes?

The Construction & Use regs require EC Category 1 anti-lock systems to be fitted to every truck registered on or after 1 April 1992 which has a GVW over 16 tonnes and is designed to pull trailers with a gross weight over 10 tonnes. ABS must also be fitted to trailers with a design weight over 10 tonnes which were first used after October 1991.

Few operators would argue with the safety benefits of ABS, but, judging by the number who rushed out to buy non-ABS tractors before the April deadline, there is still a feeling that ABS is too expensive, unreliable or both.

The IRTE's recent survey on truck electronics (CM Workshop, June) indicated that concern over ABS reliability is justified.

Of the 714 ABS-equipped vehicles surveyed, 14.6% suffered an electronic failure in six months. On trailers the failure rate was 15%; on fire engines it rose to 19%. The main problems were sensors (6.3%), wiring (3.6%), and electronic control units (3.1%).

Given those figures, hauliers could be forgiven for seeing Scania and Bosch's plans for electronic braking as just another dose of untried, fragile gimmickry.

In fact the Scania/Bosch electronically controlled braking (ELB) project dates back to 1985. Following successful trials Scania used the Hanover Show to announce "a limited production run of Bosch (ELB)-equipped Scania trucks for regular monitored use" (CM 14-20 May).

MARKET TRIALS "Providing the market accceptance trials are successful," says Scania, "ELB will become generally available during the mid-nineties."

So ELB is far from untried, but what lies behind the initials — and will it be of practical use to hard-pressed hauliers?

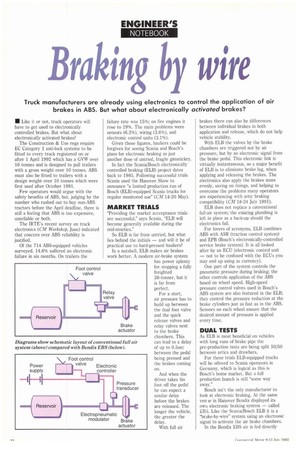

In a nutshell, ELB makes air brakes work better. A modern air-brake system has power aplenty for stopping a fully freighted

38-tonner, but it is far from

perfect, For a start, air pressure has to build up between the dual foot valve and the quick release valves and relay valves next to the brake chambers. This can lead to a delay of up to 0.5sec between the pedal being pressed and the brakes coming on.

And when the driver takes his foot off the pedal he can expect a similar delay before the brakes are released. The longer the vehicle, the greater the delay.

With full air brakes there can also be differences between individual brakes in both application and release, which do not help vehicle stability.

With ELB the valves by the brake chambers are triggered not by air pressure, but by an electronic signal from the brake pedal. This electronic link is virtually instantaneous, so a major benefit of ELB is to eliminate brake lag, when applying and releasing the brakes. The electronics also apply the brakes more evenly, saving on linings, and helping to overcome the problems many operators are experiencing with artic braking compatibility (CM 18-24 July 1991).

ELB does not replace a conventional full-air system; the exiting plumbing is left in place as a back,i.ip should the electronics fail.

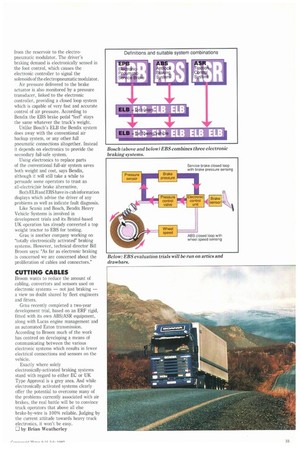

For lovers of acronyms, ELB combines ABS with ASR (traction control system) and EPB (Bosch's electronically-controlled service brake system). It is all looked after by an ECU (electronic control unit — not to be confused with the ECUs you may end up using as currency).

One part of the system controls the pneumatic pressure during braking; the other controls application of the ABS based on wheel speed. High-speed pressure control valves used in Bosch's ABS system are also featured in the ELB; they control the pressure reduction at the brake cylinders just as fast as in the ABS. Sensors on each wheel ensure that the desired amount of pressure is applied every time.

DUAL TESTS

As ELB is most beneficial on vehicles with long runs of brake pipe the pre-production tests are being split 50/50 between artics and drawbars.

For these trials ELB-equipped trucks will be offered to Scania operators in Germany, which is logical as this is Bosch's home market. But a full production launch is still "some way away."

Bosch isn't the only manufacturer to look at electronic braking. At the same ven.ie in Hanover Bendix displayed its own electronic braking system — called EBS. Like the Scania/Bosch ELB it is a "brake-by-wire" system using an electronic signal to activate the air brake chambers.

In the Bendix EBS air is fed directly from the reservoir to the electropneumatic modulator. The driver's braking demand is electronically sensed in the foot control, which causes the electronic controller to signal the solenoids of the electropneumatic modulator.

Air pressure delivered to the brake actuator is also monitored by a pressure transducer, linked to the electronic controller, providing a closed loop system which is capable of very fast and accurate control of air pressure. According to Bendix the EBS brake pedal "feel" stays the same whatever the truck's weight.

Unlike Bosch's ELB the Bendix system does away with the conventional air backup system, or any other full pneumatic connections altogether. Instead it depends on electronics to provide the secondary fail-safe system.

Using electronics to replace parts of the conventional full-air system saves both weight and cost, says Bendix, although it will still take a while to persuade some operators to trust an all-electric/air brake alternative.

Both ELB and EBS have in-cab information displays which advise the driver of any problems as well as indicate fault diagnosis.

Like Scania and Bosch, Bendix Heavy Vehicle Systems is involved in development trials and its Bristol-based UK operation has already converted a top weight tractor to EBS for testing.

Grau is another company working on "totally electronically activated" braking systems. However, technical director Bill Broom says: "As far as electronic braking is concerned we are concerned about the proliferation of cables and connectors."

CUTTING CABLES

Broom wants to reduce the amount of cabling, convertors and sensors used on electronic systems — not just braking — a view no doubt shared by fleet engineers and fitters.

Grau recently completed a two-year development trial, based on an ERF rigid, fitted with its own ABS/ASR equipment, along with Lucas engine management and an automated Eaton transmission. According to Broom much of the work has centred on developing a means of communicating between the various electronic systems which results in fewer electrical connections and sensors on the vehicle.

Exactly where solely electronically-activated braking systems stand with regard to either EC or UK Type Approval is a grey area. And while electronically activated systems clearly offer the potential to overcome many of the problems currently associated with air brakes, the real battle will be to convince truck operators that above all else brake-by-wire is 100% reliable. Judging by the current attitude towards heavy truck electronics, it won't be easy.

by Brian Weatheriey