An Entirely New Six-cylinder CROSSLEY PASSENGER CHASSIS

Page 98

Page 99

Page 100

If you've noticed an error in this article please click here to report it so we can fix it.

First and Full Particulars of a High-grade Powerful Machine Incorporating a Host of Interesting and Practical Features.

THE claim of Crossley Motors, Ltd., that it has, in the past, produced a wide variety of commercial chassis, and that in practice these vehicles have earned the concern an enviable reputation for reliability and performance, is no Idle boast.

The latest product of the well-equipped workshops of the company—a six-cylinder coach and bus chassis—has, therefore, a line of breeding, as it were, and, although new in the sense that the general layout is different from what has obtained in the past, the principles involved in the design are the result of long experience in a class of work which can only be called specialized.

There is one other point before turning to a consideration of the technical details—the new chassis is a thoroughly tested and tried proposition; indeed, the makers state that one vehicle with a 31-seater body has been on ManchesterLondon daily service without a failure and without giving the slightest trouble for just over three months.

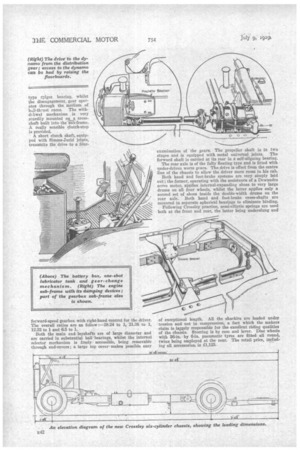

Sturdiness and a capacity for prolonged hard work seem to be the outstanding characteristics of the design, as a glance at the photographs of the tout ensemble will clearly show, yet the various components are not unduly heavy or bulky, as witness the fact that the chassis, complete with oil, water, all accessories and five gallons of fuel, scales but 3 tons 10 cwt. 2 qrs. Mention of a few of the main dimensions may not here be out of place. With wheelbase and track dimensions of 16 ft. 71 ins. and 5 ft. 111 ins, respectively, the overall length (excluding the starting handle) works out at 25 ft. 6-1 ins., and the width is 7 ft. 6 ins., whilst the left-hand turning circle is 57 ft. 5 ins. and in the opposite direction 59 ft. 2 ins.

In keeping with the modern demand for maximum passenger accommodation, the power unit has been compacted as much as possible and the driver placed in the forward position, which has resulted in the available body space being 20 ft. 91 ins. Another point worthy of comment is the fact that despite the ground clearance of 11 ins., the laden height of the frame between the axles is 1 ft. 111 ins. whilst the height of the frame at the rear overhang is but I: ft. 3 ins.

There is a kick-up of the frame over both front and rear axles, the latter part being strengthened by a welded-in flitch joining the inner edges of the frame channels. The side: members are 9 ins, deep, and they are tied together and braced diagonally to prevent any possibility of " lozenging." In passing, it may be mentioned that 12 double channelsection outriggers of pressed-steel are provided ; the body is carried on large rubber pads.

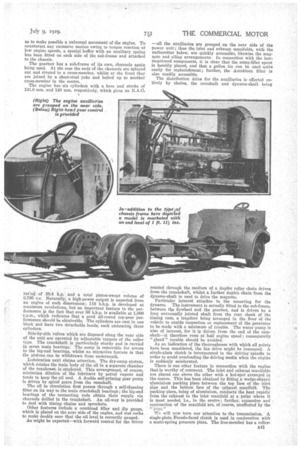

We can now turn our attention to a consideration of .the power unit, but 'before going into details it would seem opportune to mention the special arrangements that have been made to prevent chassis distortion being passed on to the crankcase or gearbox. The engine sub-frame consists of a pair of channels anchored at the rear on a cross-member with Silentbloc bushes interposed between pin-type joints, and at the front by a sheet-steel bearer arm which is pivoted on a single centre bearing.

It will be seen, therefore, that each joint is so constructed as to make possible a universal movement of the engine. To counteract any excessive motion owing to torque reaction at low engine speeds, a special buffer with an auxiliary spring has been fitted on each side of the sub-frame and attached to the chassis.

The gearbox has a sub-frame of its own, channels again being used. At the rear the ends of the channels are splayed out and riveted to a cross-member, whilst at the front they are joined by a sheet-steel yoke and bolted up to another cross-member in the centre.

The engine has six cylinders with a bore and stroke of 101.6 mm. and 140 mm. respectively, which gives an It.A.C.

rating of 38.4 h.p. and a total piston-swept volume of 6,796 c.c. Naturally, a high-power output is expected from an engine of such dimensions ; 110 b.h.p. is developed at maximum revolutions but an important feature in the per formance is the fact revolutions, over 50 b.h.p. is available at 1,000 r.p.m., which indicates that a good all-round top-gear performance should be obtainable. The cylinders are cast in one block and have two detachable heads, each embracing three • cylinders.

• Side-by-side valves which are disposed along the near side of the unit are operated by adjustable tappets of the roller type. The crankshaft is particularly sturdy and is carried in seven main bearings. The sump is removable for access to the big-end bearings, whilst an attractive feature is that the pistons can be withdrawn from underneath.

• Lubrication next claims attention. The dry-sump system, which retains the main body of the oil in a separate chamber of the crankcase, is employed. This arrangement, of course, minimizes dilution of the lubricant by petrol vapour and tends to keep the oil cool. A double self-priming gear pump is driven by spiral gears from the camshaft.

The oil in circulation first passes through a self-cleaning filter on its way to the main crankshaft bearings ; the big-end bearings of the connecting rods obtain their supply via channels drilled in the crankshaft. An oil-way is provided to deal with timing chains and sprockets.

Other features include a combined filler, and dip gauge, which is placed on the near side of the engine, and test cocks to make doubly sure that the oil level is correctly gauged. As might be expected—with forward control for the driver —all the auxiliaries are grouped on the near side of the power unit ; thus the inlet and exhaust manifolds, with the carburetter below, are quickly accessible, likewise the magneto and oiling arrangements. In connection with the lastmentioned components, it is clear that the sump-filler spout is handily placed, and that a gallon tin can be used quite easily for replenishment ; further, the Autokleen filter is also readily accessible.

The distribution drive for the auxiliaries is effected entirely by chains, the camshaft and dynamo-shaft being rotated through the medium of a duplex roller chain driven from the crankshaft, whilst a further duplex chain from the dynamo-shaft is used to drive the magneto.

Particular intereat attaches to the mounting for the dynamo. The instrument is actually fitted to the sub-frame, between tile flywheel and the gearbox, and is driven by a long universally jointed shaft from the rear cheek of the -timing case, a trapdoor being arranged in the floor of the vehicle to enable inspection or replacement of the generator to be made with a minimum of trouble. The water pump is also of interest, for it is driven from the end of the camshaft—it therefore runs at half engine speed ; consequently " gland " trouble should be avoided.

• As an indication of the thoroughness with which all points hate been considered, the fan drive might be instanced. A single-plate clutch is incorporated in the driving spindle in order to avoid overloading the driving media when the engine is suddenly accelerated. • There is one other feature in connection with the engine that is worthy of comment. The inlet and exhaust manifolds are placed one above the other with a hot-spot arranged in the centre. This has been obtained by fitting a wedge-shaped aluminium packing piece between the top face of the inlet pipe and the bottom face of the exhaust manifold. The packing piece, being of aluminium, conducts the heat rapidly from the exhaust to the inlet manifold at a point where it is most needed, le., in the centre; further, expansion and contraction -of the manifold are, of course, unaffected by the "joint."

We will now turn our attention to the transmission. A single-pIate Ferodo-faced clutch is used in conjunction with a multi-spring pressure plate. The free-member has a rollerE41 type tpigot bearing, whilst the disengagement gear operates through the medium of ha-thrust races. The withdihwal mechanism is very sturdily mounted on _a crossshaft built into the sub-frame. A really sensible clutch-stop is provided.

A short clutch shaft, equipped with Simms-Jurid joiuts, transmits the drive to a four

forward-speed gearbox with right-band control for the driver. The overall ratios are as follow :-38.24 to L 21.38 to 1, 12.22 to 1 and 6.5 to 1.

Both the main and layshafts are of large diameter and are carried in substant. al baltr bearings, whilst the internal selector mechanism is freelyaccessible, being removable through end-covers; a large top cover' makes possible easy examination of the gears. The propeller shaft is in two stages and is equipped with metal universal joints. The forward shaft is carried at its rear in a self-aligning bearing. The rear axle is of the fully floating type and is fitted with under-driven worm gears. The drive is offset from the centre line of the chassis to allow the driver more room in his cab. Both hand and foot-brake systems are very simply laid out; the former, operating with the assistance of a Dewandre servo motor, applies internal-expanding shoes to very large drums on all four wheels, whilst the latter applies only a second set of shoes inside the double-width drums on the rear axle. Both hand and foot-brake cross-shafts are mounted in separate spherical bearings to eliminate binding. Following Crossley practice, semi-elliptic springs are used both at the front and rear, the latter being underslung and of exceptional length. All the shackles are loaded under .tension and not in compression, a fact which the makers claim is largely responsible for the excellent riding qualities of the chassis. Steering is by cam and lever. Disc wheels with 36-in. by 6-in, pneumatic tyres are fitted all round, twins being employed at the rear. The retail price, including all accessories, is £1,125.