The Fleet Special Serves th€

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

■ Tews Hot

By Anthony Ellis

RESPLENDENT in bright yellow paint and colourful signwriting, the Fleet Special van which

• appeared on the Dennis stand at the Commercial Motor Show must have caught Many visitors eyes. Those who went further into the details of this 2-tanner would have realized quickly how apt was the "special" in its title.

• Dennis Bros., Ltd., Guildford, have a zeputation for satisfying their customers' special requirements and, like the Paravan (a road-test report on

which appeared in The Commercial Motor on October 31, 1958), the Fleet Special is the result of collaboration between the operator and manufacturer.

It is the brain-child of Mr. E. A. Jones, general manager of Fleet Deliveries, Ltd., 77 Kill& Street,

• London, N.1: It is his idea of the ideal van for the work on Which his organization is engaged—conveying all newspapers printed by the Daily Mirror group from their printing works in Ray Street to London railway termini for distribution throughout the country. The vans must also be capable of completing longer journeys little slower than a train.

Thus, the basic requirement was for a compact van capable of high road speeds—future possibilities opened up

by the new road system had to be considered-7–good acceleration and easy manceuvrability in dense London traffic. Although the average payload of vans used at the moment is only about a ton, the rising circulation of papers in the group and the tendency towards larger newspapers called for a vehicle capable of carrying at least two tons.

The vehicle which I was given to road test was the first production Fleet Special. A prototype has been in operation with Fleet Deliveries since early last year. Derived from the Dennis Heron chassis, the new model is powered by the Dennis four cylindered 3.77 litre

overhead-valve petrol engine. . To ensure, good performance, the Hendy governor is set for this application, at 3,200 r.p.m., the normal limit

being 2,900 r.p.m. The higher figure is still 300 r.p.rn. below

the point at which valve bounce occurs. The sizes of choke,main and compensating jets of the single Zenith carburetter are also increased. Although one might .think

this would seriously increase fuel consumption, the figure of 12.6 m.p.g. recorded during the test while carrying a load of slightly over two tons shows that economy has suffered little.

The four-speed gearbox has inertialock synchromesh engagement of the three upper gears. Whereas on the standard Heron chassis it is operated directly by a forward cranked lever, a remote control linkage has been designed for the new vehicle.

Mr. Jones originally requested a gear lever mounted on the steering column but this was not practicable. The lever is mounted on the engine, operating through a universal joint and a curved rod. It lies ideally under the driver's left hand almost level with the steering wheel to give a first-class gear-change for a short movement. The excellent acceleration figures obtained reflect in some part the excellence of this combination.

The standard Heron hypoid-bevel rear axle is used, but in view of the reduced payload single rear wheels are fitted in place of the normal twins. This also narrows the tear track and tends to reduce damage to tyres through striking kerbs. Although during the test the narrow rear track seemed to increase roll, it did not do so to an uncomfortable or dangerous extent.

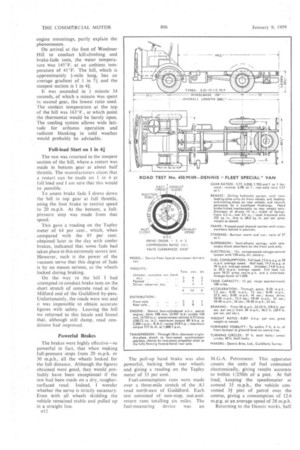

As tested, the van was carrying a load of sandbags and 56 lb. weights totalling 2 tons 1.1. cwt. Having an unladen weight of 2 tons 81 cwt., it was thus running at 4 tons 14 cwt., with myself and Mr„ L. Jackson, of Dennis Bros., aboard. Weight distribution over the 8.25-15 in. (12-ply) tyres was almost perfect, with 2 tons 54 cwt. on the front axle and 2 tons 81 cwt. on the rear.

On the way to the acceleration test course on a level stretch of road between Guildford and Godalrning it was at once apparent that here was no mean performer, even fully loaded. For the standing-start tests, first gear was used up to about 9 m.p.h., second to 18 m.p.h., with the change into direct drive made at 33 m.p.h.

As these were the approximate theoretical cut-off points for the governor, this unit was obviously working well and the transmission ratios were correctly chosen for the engine characteristics. The time of 15 seconds taken to reach 30 m.p.h. was extremely good for a commercial vehicle running at more than 4 tons and indicates the ability of the van to keep up with almost any traffic.

The absence of an air cleaner or intake silencer from the engine of the vehicle tested was made apparent by loud induction roar at large throttle openings. It would seem a pity that at least a simple silencer could not be fitted to overcome this minor criticism.

On the direct-drive acceleration tests it was possible to engage top gear before the speedometer needle started to move from its stop, showing the flexibility of the engine when cornbined with a 5.57 to 1 ratio rear axle. • From this point, about 5 m.p.h., the vehicle accelerated smoothly up to its maximum speed.

There was at no point in the speed range any transmission judder or noticeable vibration, whilst the time taken between each increment of 10 m.p.h.—approximately 13 seconds —was consistent. So smooth was the engine during these tests that one had almost to be reminded that the power unit had only four cylinders; the good engine mountings, partly explain the phenomenon.

On arrival at the foot of Woolmer Hill to conduct hill-climbing and brake-fade tests, the water temperature was 145°F. at an ambient temperature of 41°F. The hilt, which is approximately +-mile long, has an average gradient of 1 in 71 and the steepest section is 1 in 44.

It was ascended in 1 minute 34 seconds, of which a minute was spent in second gear, the lowest ratio used. The coolant temperature at the top of the hill was 163°F., at which point the thermostat would be barely open. The cooling system allows wide latitude for arduous operation and radiator blanking in cold weather would probably be advisable.

Full-load Start on 1 in 41,1

The van was returned to the steepest section of the hill, where a restart was made in bottom gear at about half throttle, The manufacturers claim that a restart can be made on 1 in 4 at full load and I am sure that this would be possible.

To assess brake fade I drove down the hill in top gear at full throttle, using the foot brake to restrict speed 16 20 m.p.h. At the bottom, a fullpressure slop was made from that speed.

. This gave a reading on the Tapley meter of 64 per cent., which, when compared with the 85 per cent. obtained later in the day with cooler brakes, indicated that some fade had taken place in this extremely severe test. However, such is the power of the vacuum servo that this degree of fade is by no means serious, as the wheels locked during braking.

On the way to the hill I had attempted to conduct brake tests on the short stretch of concrete road at the Milford end of the Guildford by-pass, Unfortunately, the roads were wet and it was impossible to obtain accurate figures with safety. Leaving the hill we returned to this locale and found that, although still damp, road conditions had improved.

Powerful Brakes

The brakes were highly effective—so powerful in fact, that when making full-pressure stops from 20 m.p.h. or 30 m.p.h., all the wheels locked for the full distance. Although the figures obtained were good, they would probably have been exceptional if the test had been made on a dry, roughersurfaced road. Indeed, I wonder whether the servo is strictly necessary. Even with all wheels skidding the vehicle remained stable and pulled up in a straight line. The pull-up hand brake was also powerful, locking both rear wheels and giving a reading on the Tapley meter of 33 per cent.

Fuel-consumption runs were made over a three-mite stretch of the A3 road north-east of Guildford. Each test consisted of non-stop, out-andreturn runs totalling six miles. The fuel-measuring device was an M.G.A. Petrometer. This apparatus counts the units of fuel consumed electronically, giving results accurate to within 1/250th of a pint. At full load, keeping the speedometer at around 35 m.p.h., the vehicle consumed 3f pint of petrol over the course, giving a consumption of 12.6 m.p.g. at an average speed of 28 m.p.h.

Returning to the Dennis works, half the test load was removed to reduce the all-up weight to about 3 tons 13 cwt. Afurther run was then undertaken, which gave 143 m.p.g. at an average speed of 30 m.p.h. The remainder of the load was then removed and an unladen run was carried out at 30.3 m.p.h. for a fuelconsumption rate of 14.8 m.p.g.

When the van was fully laden, I made a fast'run to estimate the fuel consumption when it was driven "flat out." Employing a leaden-right-foot technique over the same course with the speedometer needle, wherever possible, above the 50 m.p.h. mark and on occasions just below 60 m.p.h., a run was made at an average speed of 36.6 m.p.h., with a fuel-consumption return of 9.9 m.p.g.

Performance First

For an engine which has been deliberately upratcd for performance without thought for economy, these figures are commendable. Even when driven hard on town work, the fuelconsumption rate is not likely to drop below 11 m.p.g. when running unladen half the time, as Fleet Deliveries' vans do, whilst on long runs, laden in only one direction, the figure should be of the order of 13 m.p.g. The prototype Fleet Special bears out this belief, as it has averaged about 12 m.p.g. while it has been in service.

Wishing to see how the van performed on its home ground 1 spent a day driving it in London. As it was unladen, the acceleration was obviously even better than it had been during the scheduled tests, making it possible to keep up with, and even overtake, private cars in London traffic.

Easy to Manceuvre An extremely good lock giving a turning circle of 37 ft. and good forward vision make the van highly manoeuvrable and pleasant to drive in congested conditions. When laden, I had noticed that the steering tended to be rather woolly and to have little self-centring action. This characteristic was not nearly as apparent when the load was removed and I assumed that it was in some part caused by the rather large tyres.

Apart from the provision of an accessible gear lever, Mr. Jones and Dennis Bros. have paid much other attention to the comfort of the driver. Ease of entry is one of the features 'of the cab, the door-sill line of which is tow because of the use of 15-in. wheels. Wide steps are provided at hub level on each side, whilst large and robust grab rails help the driver to get in and out. The sliding doors have deep drop windows which give good sideways vision. Although fabricated of metal panels on a wooden frame, the cab and body share a translucent plastics roof panel.

Detail refinements in the construction of the body and chassis can be seen in the design of the front bumper and in the shutter used at the rear. The bumper is extended around the front quarters to combine with the wheel-arches. The gap between it and the body is filled by chequer-plate decking to form both the entrance steps and a ledge on which the driver can stand to clean the divided windscreen.

The rear shutter is of plastics construction made up of a one-piece resinreinforced glass-fibre sheet braced laterally by bonded-in angle strips of similar material. Running in a channel, it relies on the flexibility of the plastics to allow it to curve upwards into the roof. Although rather stiff to operate, it could easily be assisted by a spring or a similar mechanical aid.

Wooden shutters previously used by Fleet Deliveries have had a short life, as the vehicles are often driven with the shutters up, causing constant hammering and consequent damage.

Good Driving Position

The two-way adjustable seat for the driver is well situated with regard, to the pedals and gives a good alert driving position. Otherwise well equipped, the cab had no interior light, although one was fitted in the body.

Great care has been taken to ensure good accessibility to units requiring a regular servicing. The top of the engine cowling is readily removable by releasing three spring clips. It has a trap to give access to the oil filler, whilst another trap in the near side of the cowl allows the dipstick to be reached. Using this side trap I was able to check the oil level in 17 seconds without difficulty.

The battery is housed under the cab

floor beneath the passenger's feet. It is covered by a hinged chequer-plate trap secured by a single fastener. The trap was opened, the level of the six cells inspected and the cover secured in 60 seconds.

Two panels are incorporated in the near side of the engine cowl, which, when removed, reveal the sparking plugs. I was unable to remove a plug because it was not possible to obtain a suitable box spanner. The sparking plugsused in the Dennis engine are 18 mm. and no tool kits or spare wheels are provided with the vehicles supplied to Fleet Deliveries. However, given the correct tool, this would cause no difficulty.

Engine Accessible

A large removable panel is also fitted in the near side of the cowl to give access to the inlet and exhaust manifolds. Separate master cylinders for the hydraulic clutch mechanism and braking system are located under the floor on the driver's side of the cab and reached through two hinged traps. In all, the engine and its accessories will create few accessibility problems during routine maintenance.

As I did not have a jack it was also impossible to adjust the brakes, but as these are taken up by single squareheaded nuts on the brake back-plates, they, too, should present little difficulty.

Attractive in appearance and almost completely vice-free, whilst giving a remarkable performance, the Fleet Special is an excellent example of how far a specialized manufacturer can go to give complete satisfaction to the operator. Although it has naturally proved to be much more expensive than a mass-produced equivalent would be, it does its specified job as no other vehicle offered can.

The proof of a vehicle is in the driving and Mr. Jones, after nearly a year's experience with the prototype, has drivers clamouring for delivery of the remaining 16 vehicles which constitute the original order.